Preparation and regeneration method of pythium oligandrum protoplasts and composite enzymatic hydrolysate

A compound enzymatic solution and protoplast technology, applied in the field of microbial protoplast preparation and regeneration, can solve the problems of inability to complete the preparation of Pythium oligandrum, the inability to remove the cell wall of Pythium oligandrum, and the difference in cell wall components, so as to achieve regeneration rate High, maintain integrity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation and regeneration of Pythium oligandrum protoplasts.

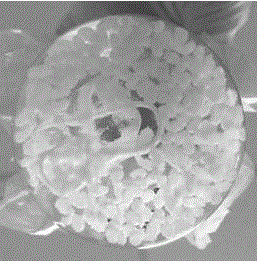

[0030] Inoculate Pythium oligandrum hyphae discs on PDA plate medium, culture at 26°C for 4 days, and scrape off all the mycelium and spore mixture on the 4 plates with a sterile inoculation loop (about 1g ), placed in a centrifuge tube; with 5mL osmotic pressure stabilization solution (0.8M mannitol, 25mM CaCl 2 , 10mM Tris-HCl pH7.5) wash the mixture of mycelia and spores, 5500rpm, centrifuge for 10min, repeat the washing and centrifugation for 3 times, and collect the mixture of mycelia and spores of Pythium oligandrum; the mixture of mycelia and spores of Pythium oligandrum collected in the previous step Add compound enzymatic hydrolysis solution (4mL 1%lysing enzyme + 4mL1%cellulase+200U lyticase), fully dissolve for enzymolysis, 30℃, 80rmp, enzymolysis for 2h, to obtain Pythium oligandrum protoplasts; The mixture of mycelium protoplasts and mycelial spore residues was filtered through 4 l...

Embodiment 2

[0033] Example 2 The composition determination experiment of the compound enzymatic hydrolyzate.

[0034] According to the method described in Example 1, different ratios of lysing enzyme, cellulase, and lyticase were used to enzymolyze the mixture of Pythium oligandrum mycelium spores, collect protoplasts, measure the concentration of protoplasts, and perform protoplast regeneration experiments to determine the protoplasts Regeneration rate, according to the experimental results to determine the best composition of the compound enzymatic hydrolyzate, the experimental results are shown in the table below.

[0035]

[0036] It can be seen from experiments that using one of lysing enzyme, cellulase or lyticase alone (such as ⑴~⑶), or enzymatically cleaving Pythium oligandrum mycelia without the participation of lyticase (such as ⑷), cannot make oligoandrum Pythium male releases protoplasts. When the activity of lyticase added to 1g of mycelia exceeds 200U (such as ⑿), it will ...

Embodiment 3

[0037] Example 3 Determination of the enzymatic hydrolysis time of the compound enzymatic hydrolyzate.

[0038] Using the composite enzymolysis solution determined in Example 2, i.e. 4mL 1%lysing enzyme+4mL1%cellulase+200U lyticase, respectively enzymatically hydrolyze the Pythium oligandrum mycelium spore mixture for 1h, 1.5h, 2h, 2.5h, 3h, 4h, 5h and overnight, and the rest of the method is the same as in Example 1, and the preparation of protoplasts is observed.

[0039] The experimental results showed that after 1 hour and 1.5 hours of enzymatic hydrolysis, there were more bacteria that had not been enzymatically hydrolyzed, and less protoplasts were released; Not good; after overnight enzymatic hydrolysis, the protoplasts were all enzymatically hydrolyzed into debris residues; after 2-3 hours of enzymatic hydrolysis, a large number and high activity of Pythium oligandrum protoplasts could be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com