A kind of ultra-high molecular weight polyethylene fiber surface functionalization treatment method

An ultra-high molecular weight, polyethylene fiber technology, which is applied in fiber processing, textiles and papermaking, etc., can solve problems such as high equipment requirements, difficult resin wetting, and reduced fiber strength due to oxidation, to achieve uniform functionalization and improve viscosity. The effect of knot strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

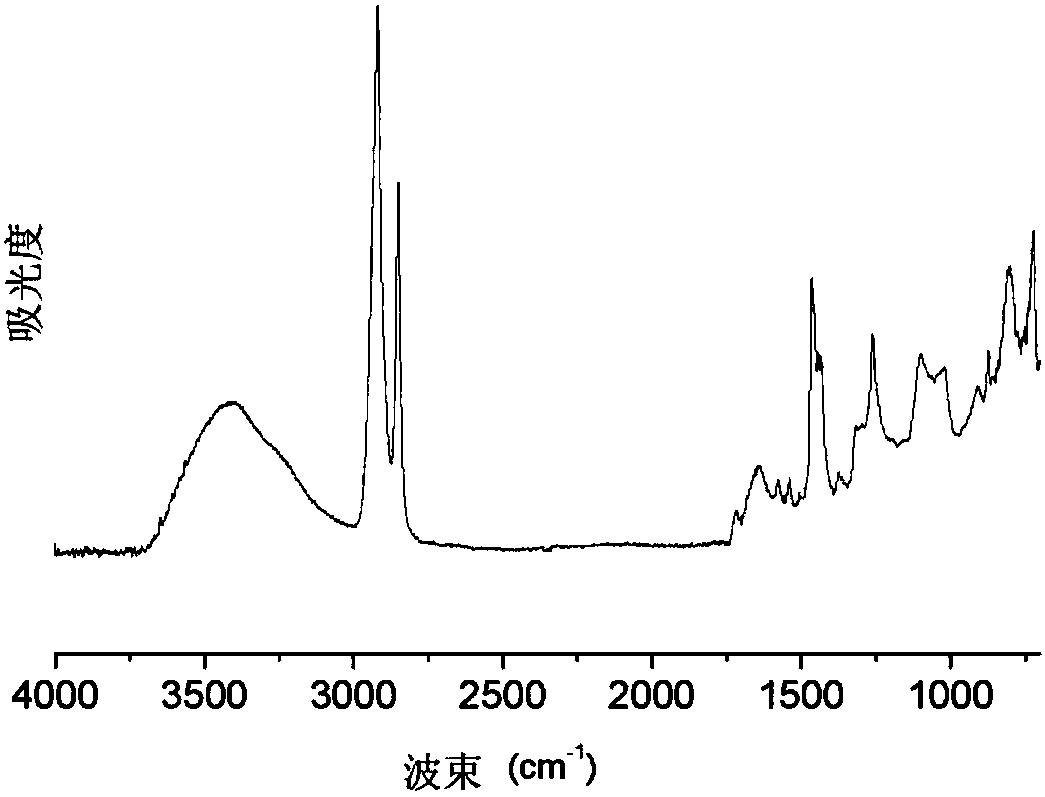

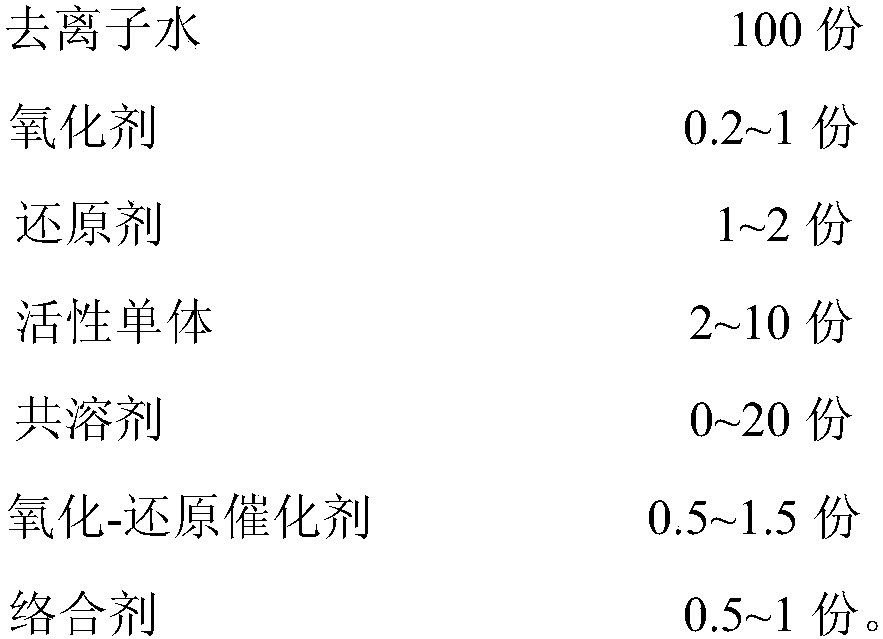

[0026] The surface chlorination reaction of UHMWPE fiber is carried out through the chlorinated aqueous phase system. The chlorinated aqueous solution contains: 100 parts of deionized water, 0.4 parts of chlorine, the reaction temperature is 65 ° C, and the chlorination degree is 30 through the immersion time in the water tank for 10 minutes. % of UHMWPE fiber surface, UHMWPE fiber after surface chlorination undergoes atomic group transfer reaction through grafting reaction aqueous solution, and its grafting reaction aqueous solution contains: 100 parts of deionized water, 0.2 part of oxidant CuCl 2 , 1 part of reducing agent ethylene glycol, 3 parts of active monomer hydroxyethyl methacrylate, 1 part of redox catalyst sodium carbonate, 0.5 part of complexing agent pyridine, the grafting reaction temperature is 40 ° C, the reaction time is 30 min, then The fibers after branching reaction were washed in a water tank and dried with hot air at 80°C to obtain UHMWPE fibers with hyd...

Embodiment 2

[0029] The surface chlorination reaction of UHMWPE fibers is carried out through the chlorine-containing aqueous phase system. The chlorination aqueous solution contains: 100 parts of deionized water, 0.25 parts of chlorine, the reaction temperature is 75 ° C, and the chlorination degree is 30 after the immersion time in the water tank for 5 minutes. % of the UHMWPE fiber surface, the UHMWPE fiber after surface chlorination undergoes atomic group transfer reaction in the grafting reaction aqueous solution, and the grafting reaction aqueous solution contains: 100 parts of deionized water, 0.5 parts of oxidant CuBr 2 , 4 parts of active monomer hydroxyethyl methacrylate, 1 part of reducing agent glycerin, 1 part of redox catalyst sodium carbonate, 0.5 parts of complexing agent bipyridine, the grafting reaction temperature is 50 ° C, and the reaction time is 20 minutes , the fibers after the grafting reaction were washed in a water tank and dried with hot air at 80°C to obtain UHM...

Embodiment 3

[0032] The surface chlorination reaction of UHMWPE fiber is carried out through the chlorinated aqueous phase system. The chlorinated aqueous solution contains: 100 parts of deionized water, 0.3 parts of chlorine, the reaction temperature is 60 ° C, and the chlorination degree is 30 through the immersion time in the water tank for 10 minutes. % of the UHMWPE fiber surface, the UHMWPE fiber after surface chlorination undergoes atomic group transfer reaction in the grafting reaction aqueous solution, and the grafting reaction aqueous solution contains: 100 parts of deionized water, 0.6 parts of oxidant CuCl 2 / FeCl 3 (recombined at a molar ratio of 1:0.2), 6 parts of active monomer hydroxypropyl methacrylate, 1 part of reducing agent glucose, 1 part of redox catalyst disodium hydrogen phosphate, 0.6 part of complexing agent tris-(2-di Methylaminoethyl)amine, the grafting reaction temperature is 70°C, and the reaction time is 15min. After the grafting reaction, the fibers are was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com