Process for preparing metal silver micropattern on polymeric material surface

A technology of polymer materials and process methods, which is applied in the field of preparing metallic silver micropatterns on the surface of polymer materials, can solve problems such as the complexity of the silver plating process, and achieve the effects of uniform functionalization, high fidelity, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

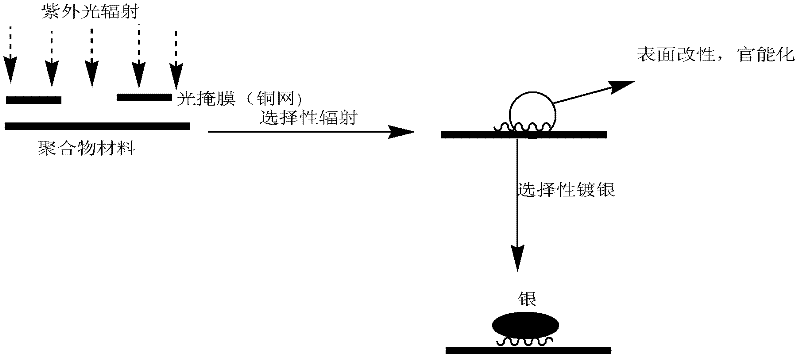

Method used

Image

Examples

Embodiment 1

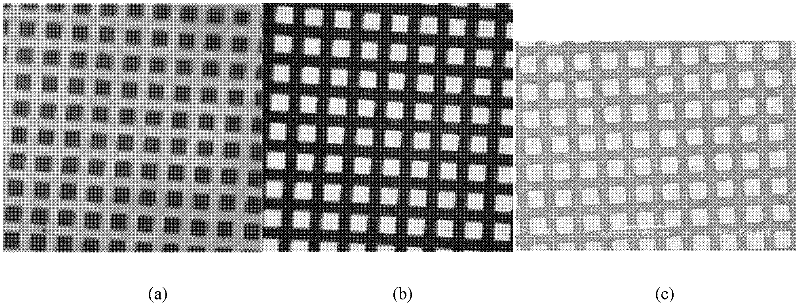

[0018] Example 1 Preparation process of metal patterning on the surface of polyethylene terephthalate (PET) material:

[0019] 1) Cleaning of PET substrate:

[0020] First cut the PET substrate into 1cm×1cm sheet, soak it with lye (sodium hydroxide: 60g / L, anhydrous sodium carbonate: 15g / L, washing powder: 35g / L, control the solution temperature to 65℃) After 10 minutes to remove the grease on the surface, pour off the lye, and repeatedly rinse the polymer substrate with distilled water until the pH of the distilled water after rinsing is ≈ 7, indicating that the lye on the surface of the substrate has been rinsed, and then reflux with acetone for 24 hours. After reflux, ultrasonically clean with toluene, ethanol, and deionized water for 10 minutes in sequence, and blow dry with nitrogen, and set aside;

[0021] 2) Modification of PET substrate:

[0022] Fix the photomask (copper mesh, with a line width of about 20 μm) on the surface of the PET substrate with clips, place it...

Embodiment 2

[0032] Example 2 Preparation process of metal patterning on the surface of polyimide (PI) material:

[0033] (1) Cleaning of PI substrate:

[0034]First cut the PI base material into 1cm×1cm sheet, use lye (sodium hydroxide: 60g / L, anhydrous sodium carbonate: 15g / L, washing powder: 35g / L, control the solution temperature to 65 ° C) Soak for 10 minutes to remove the grease on the surface. After that, pour off the lye, and rinse the polymer substrate repeatedly with distilled water until the pH of the distilled water after rinsing is ≈ 7, indicating that the lye on the surface of the substrate has been rinsed clean, and then use The acetone was refluxed for 24 hours. After the reflux was completed, it was washed with toluene, ethanol, and deionized water in sequence for 10 minutes, and then dried with nitrogen gas for later use.

[0035] (2) Modification of PI substrate:

[0036] Fix the photomask (copper mesh, with a line width of about 20 μm) on the surface of the PI substra...

Embodiment 3

[0045] Example 3 Preparation process of metal patterning on the surface of polystyrene (PS) material:

[0046] (1) Cleaning of PS substrate:

[0047] First cut the PS base material into 1cm×1cm sheet, use lye (sodium hydroxide: 60g / L, anhydrous sodium carbonate: 15g / L, washing powder: 35g / L, control the solution temperature to 65 ° C) Soak for 10 minutes to remove the grease on the surface. After that, pour off the lye, and rinse the polymer substrate repeatedly with distilled water until the pH of the distilled water after rinsing is ≈ 7, indicating that the lye on the surface of the substrate has been rinsed clean, and then use The acetone was refluxed for 24 hours. After the reflux was completed, it was washed with toluene, ethanol, and deionized water in sequence for 10 minutes, and then dried with nitrogen gas for later use.

[0048] (2) Modification of PS substrate:

[0049] Fix the photomask (copper mesh, with a line width of about 20 μm) on the surface of the PS subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com