High-tap-density lithium-rich manganese-based positive electrode material and preparation method therefor

A positive electrode material and system technology, which is applied in the field of high tap density lithium-rich manganese-based positive electrode materials and its preparation, can solve the problems of low porosity, low tap density, and poor rate performance, and achieve low porosity and high tap density , Excellent electrochemical performance and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

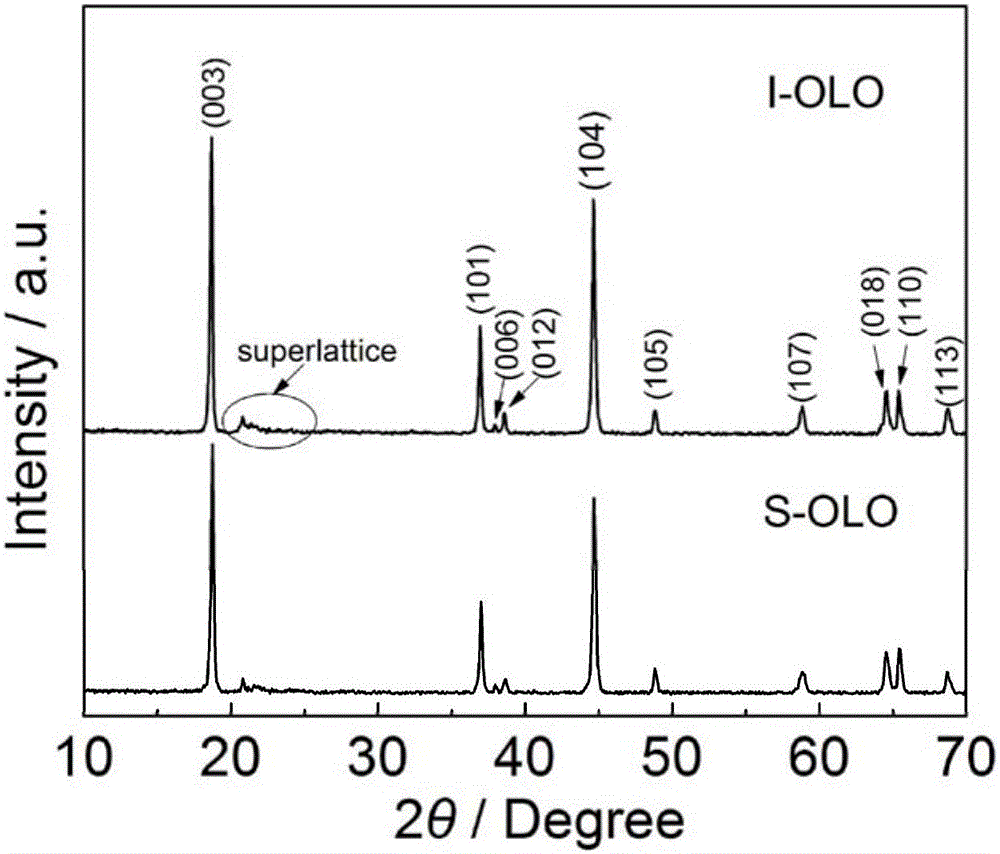

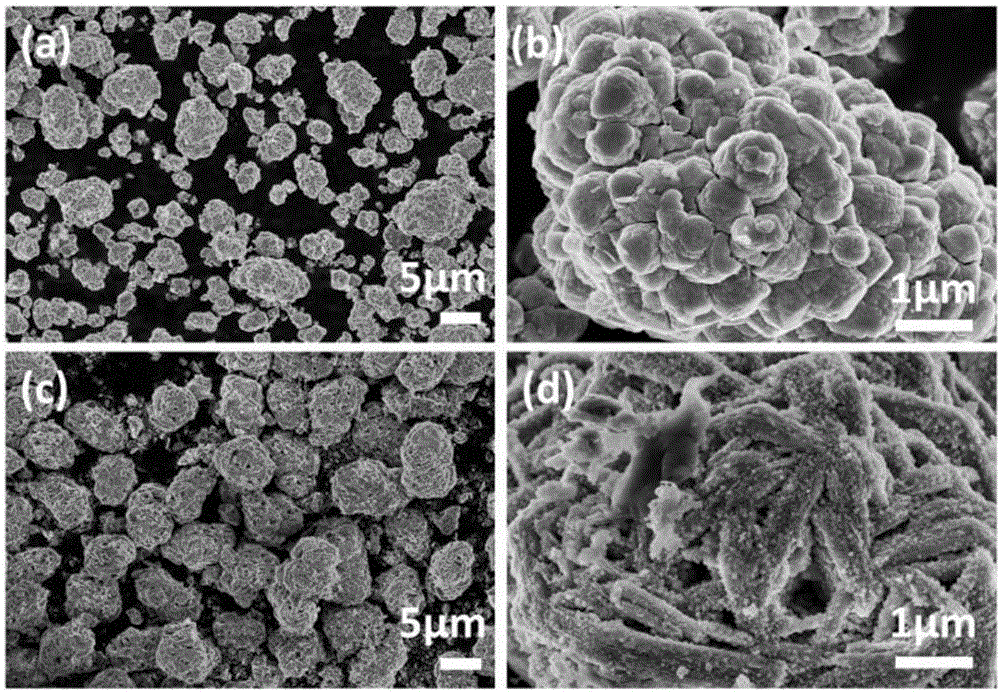

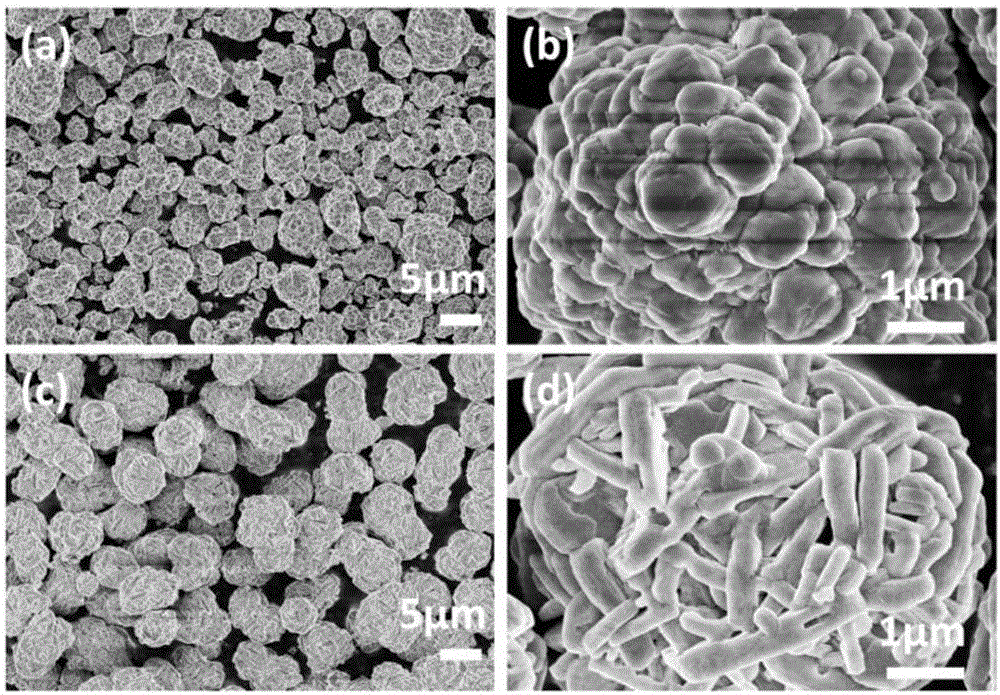

[0030] Under air atmosphere, 2.0mol / L MSO 4 (M=Mn, Ni, Co, where Mn:Ni:Co molar ratio is 0.54:0.13:0.13) solution and 5.0mol / L NaOH solution were added dropwise to the reaction vessel at a rate of 0.5ml / min to control the pH value is 10.0, and the co-precipitation reaction temperature is controlled at 50°C. After the reaction, washing and drying are carried out to obtain the precursor of secondary particles composed of micron-sized spherical primary particles with a wide particle size distribution ( figure 2 A and b are the XRD pattern of the prepared precursor), and the dried precursor was mixed with LiOH·H 2 O mixed evenly, then placed in a tube furnace, heated at 3°C / min to 500°C and then held for 6 hours, then raised to 900°C at 3°C / min and held for 15 hours to obtain a manganese-based lithium-rich positive electrode with high tap density Material( figure 1 I-OLO is the XRD pattern of the prepared cathode material, image 3 A and b are the SEM images of the prepared po...

Embodiment 2

[0032] Under air atmosphere, 1.5mol / L MNO 3 (M=Mn, Ni, Co, where Mn:Ni:Co molar ratio is 0.5:0.2:0.1) solution and 5.0mol / L NaOH solution were added dropwise to the reaction vessel at a rate of 0.5ml / min to control the pH value is 10.0, and the co-precipitation reaction temperature is controlled to be 30°C. After the reaction, washing and drying are carried out to obtain a precursor of secondary particles composed of micron-sized spherical primary particles and a wide particle size distribution. The dried precursor with Li 2 CO 3 Mix evenly, then place in a tube furnace, raise the temperature at 3°C / min to 600°C and keep it for 5 hours, then raise the temperature to 900°C at 5°C / min and keep it for 15 hours to obtain a manganese-based lithium-rich cathode material with high tap density , assembled into a CR2032 button battery with this material, and tested the electrochemical performance.

Embodiment 3

[0034] Under air atmosphere, 2.5mol / L MSO 4 (M=Mn, Ni, where the molar ratio of Mn:Ni is 0.6:0.2) solution and 2mol / L KOH solution were added dropwise to the reaction vessel at a rate of 0.2ml / min, and the pH value was controlled to be 10.0 to control the co-precipitation reaction The temperature is 60°C. After the reaction, washing and drying are carried out to obtain the precursor of secondary particles composed of micron-sized spherical primary particles and with a wide particle size distribution. The dried precursor is mixed with LiNO 3 Mix evenly, then place in a tube furnace, raise the temperature at 5°C / min to 600°C and keep it for 4 hours, then raise the temperature to 850°C at 3°C / min and keep it for 18 hours to obtain a manganese-based lithium-rich cathode material with high tap density , assembled into a CR2032 button battery with this material, and tested the electrochemical performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com