Enzyme

An enzyme preparation and manufacturing method technology, applied in the directions of enzymes, enzyme stabilization, oxidoreductase, etc., can solve the problems of insufficient aldehyde odor effect and other problems, and achieve the effect of reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Add 0.01 parts of acetic acid bacteria strain (Gluconacetobacter swingsii QPJ strain) to 0.5 parts of glucose, 0.5 parts of yeast extract, 4.8 parts of ethanol, 1.5 parts of acetic acid, and 92.7 parts of clear water. Start culturing at 0.1 L / min. The Gluconacetobacter swingsii QPJ strain is obtained from Gluconacetobacter swingsii used for making vinegar by screening the strains that can grow under the acidity of 6% or more of acetic acid.

[0080]18 hours after the start of the culture, the aeration was stopped when the acidity of acetic acid reached 2.2%, and the culture was stopped to obtain the acetic acid bacteria culture solution. The obtained acetic acid bacteria culture solution was centrifuged at 10,000 rpm, concentrated to 10% solid content, and then fully mixed with a citric acid buffer solution (pH 5) that was 10 times the concentration in terms of mass. Centrifugation at a rotational speed of 10,000 rpm was performed again, and the supernatant was removed...

Embodiment 2、3 and comparative example 1、2

[0093] In Example 1, the acidity of acetic acid to stop the cultivation is as shown in Table 1. Except that, the acetic acid bacteria were cultivated in the same manner as in Example 1, and a deodorization test was carried out using the obtained liquid enzyme preparation. hydrogenase activity.

[0094] Here, the acetic acid culture solution of Comparative Example 1 is the acetic acid culture solution at the start of the culture.

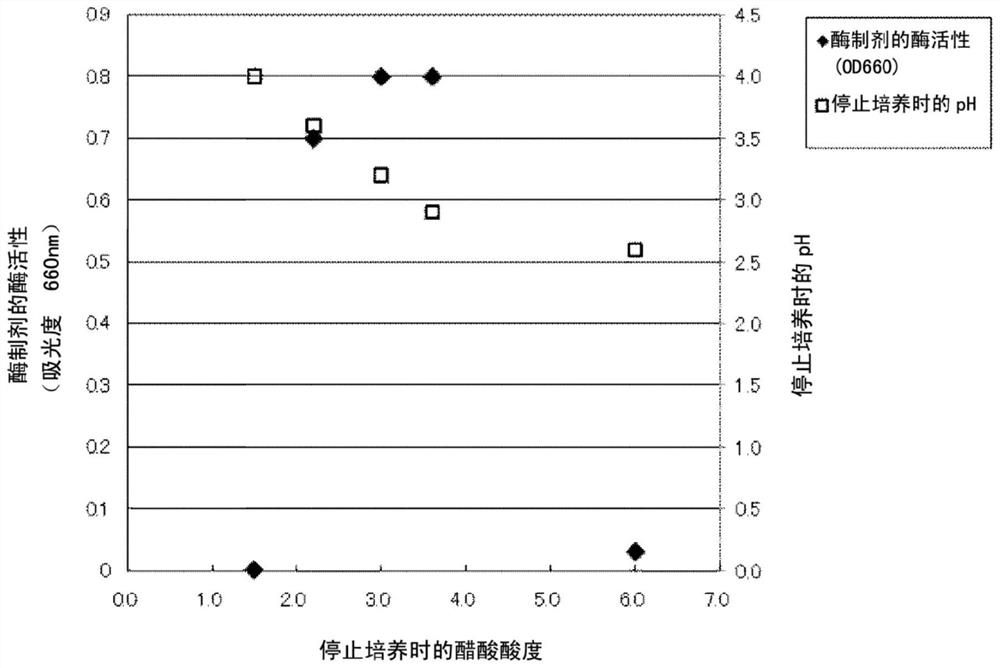

[0095] Table 1 shows the deodorizing test results and the measurement results of aldehyde dehydrogenase activity in Examples 1 to 3 and Comparative Examples 1 and 2. In addition, the relationship between the acidity of acetic acid and the absorbance or pH at the time of the termination of their culture is shown in figure 1 .

[0096] [Table 1]

[0097] Comparative example 1 Example 1 Example 2 Example 3 Comparative example 2 Acetic acid acidity when the culture was stopped 1.5 2.2 3.0 3.6 6.0 pH when the culture...

Embodiment 4

[0106] Gluconacetobacter xylinum QPJ strain was used instead of the Gluconacetobacterswingsii QPJ strain of Example 1. The Gluconacetobacter xylinum QPJ strain is obtained by selecting bacteria that can grow at an acetic acid acidity of 6% or more from Gluconacetobacter xylinus used for making vinegar.

[0107] Using this strain, the cultivation was stopped under 3.7% acetic acid acidity, except that, a liquid enzyme preparation was obtained in the same manner as in Example 1, and the activity of the aldehyde dehydrogenase was measured. 0.8. In addition, when a deodorization test was performed on acetaldehyde and nonenal in the same manner as in Example 1, both the acetaldehyde and nonenal odors disappeared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com