A carrier assembly for ceramic packaging power devices and its manufacturing method

A power device and ceramic packaging technology, which is applied in the manufacture of printed circuits, assembly of printed circuits with electrical components, electrical components, etc., can solve the problem of relatively high processing precision of heat conduction blocks, large influence of heat conduction of power devices, and variable heat dissipation capacity of power devices. To achieve the effect of solving heat conduction and stress matching problems, lowering temperature, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

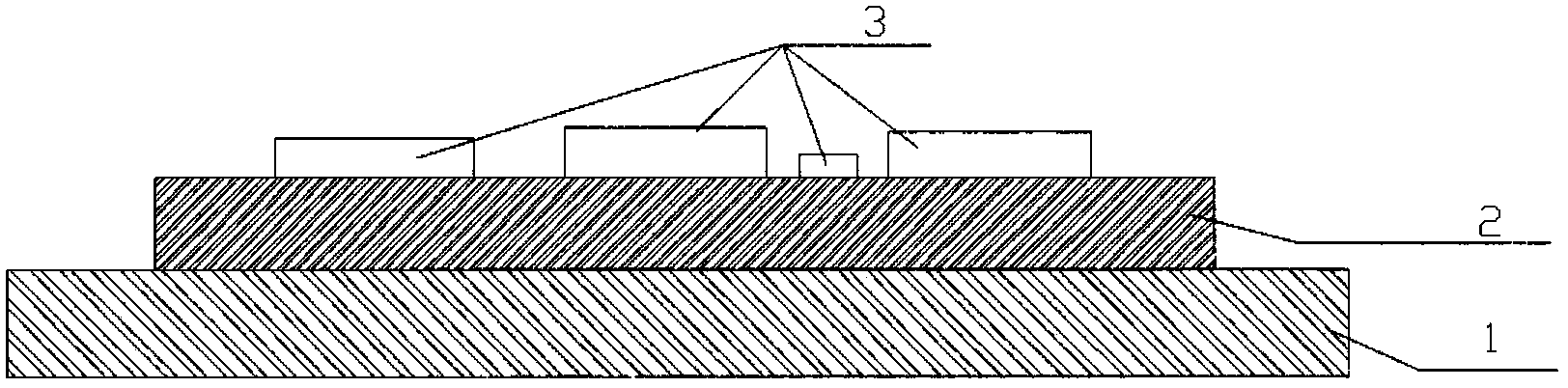

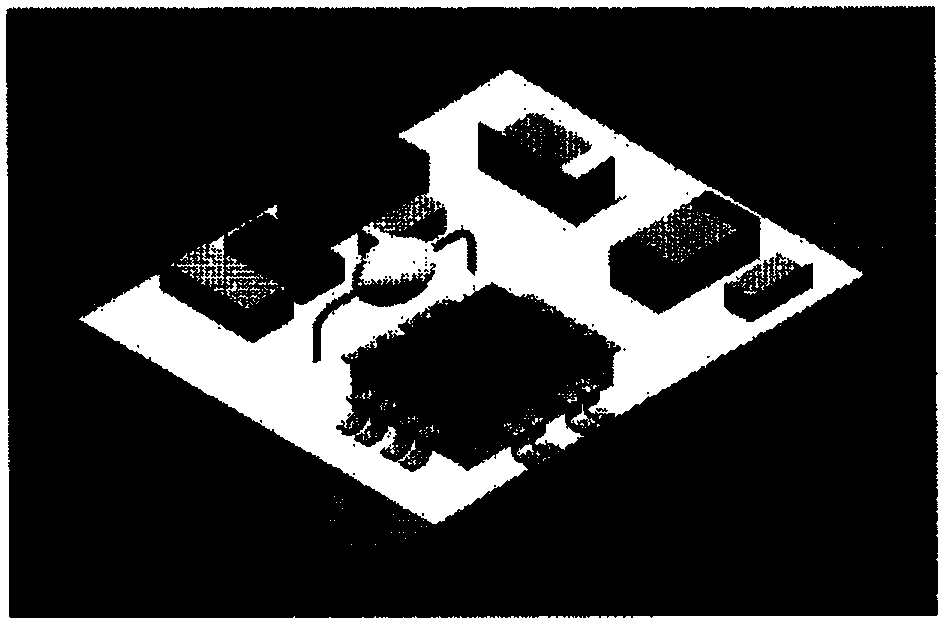

[0026] Such as figure 1 As shown, the carrier assembly of the present invention includes a ceramic circuit board and a carrier assembly substrate; the ceramic circuit board is coated with copper on both sides, and the back of the circuit board is spaced with a ventilation groove; the carrier assembly substrate is made of molybdenum copper material, and the upper surface of the substrate The surface is electroplated with lead-tin alloy; the ceramic circuit board and the substrate of the carrier component are welded together with lead-tin alloy.

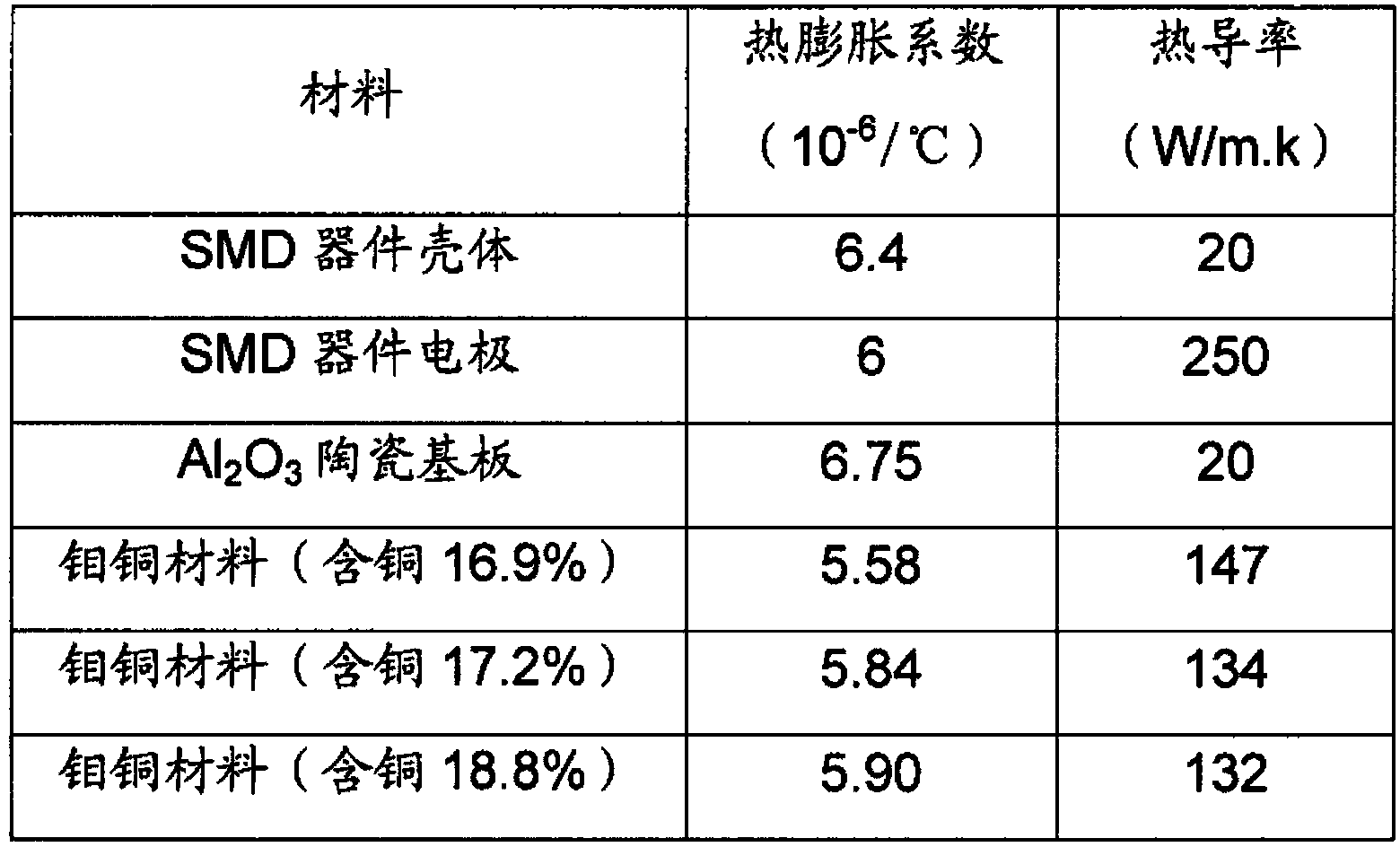

[0027] In order to ensure that the material of the substrate of the carrier assembly has a similar thermal expansion coefficient and conductivity to ceramics and SMD power devices packaged in ceramics, the thermal expansion coefficients and thermal conductivity of several materials shown in the table below are obtained according to experiments. By comparison, molybdenum-copper alloy is selected as the raw material of the substrate of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com