A Cracking Catalyst Containing Modified Beta Zeolite

A beta zeolite and catalyst technology, applied in the field of catalytic cracking catalysts, can solve problems such as low liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

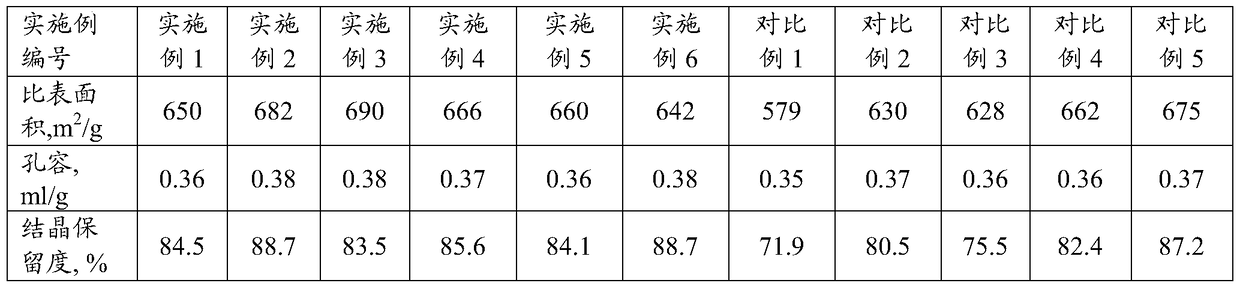

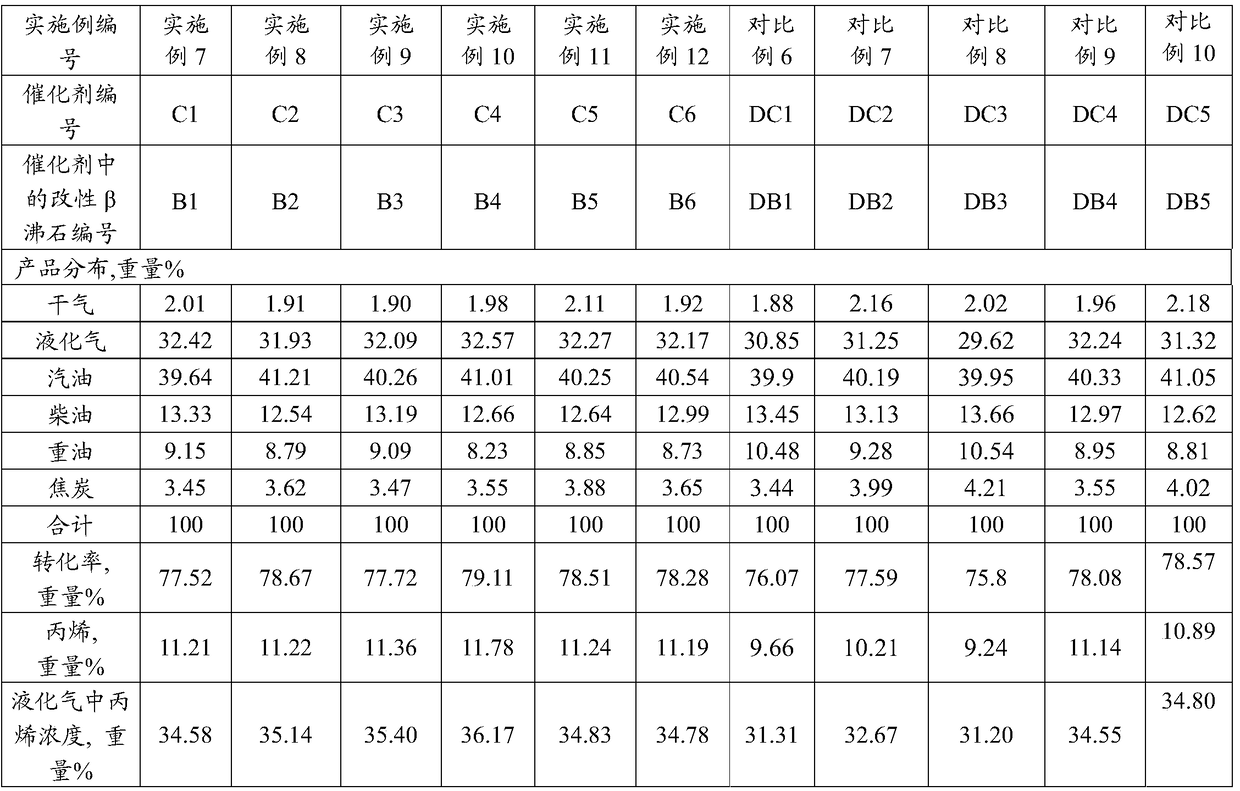

Examples

Embodiment 1

[0033] Get 200g sodium type β zeolite (production of Sinopec Catalyst Qilu Branch, SiO 2 / Al 2 o 3 =25 (molar ratio), dry basis accounts for 75% by weight), after beating with 1500g deionized water, add 45 grams (NH 4 ) 2 SO 4 and 45 mL RECl 3 Solution (RE 2 o 3 Concentration 270 g / liter, the same below), heated up to 90°C for exchange for 1 hour, filtered and washed with deionized water, and roasted for 2 hours at 600°C and 100% steam to obtain zeolite beta after rare earth exchange, with a water content of 3 wt. %, denoted as A-1;

[0034] 5.23g zirconium nitrate Zr (NO 3 ) 4 ·5H 2 O was dissolved in 150g ethanol (analytically pure) to obtain an impregnating solution, and then the above impregnating solution was mixed with rare earth-exchanged zeolite A-1 evenly, left to stand for 24 hours, dried at 100°C for 24 hours, and dried in a nitrogen atmosphere at 500°C Lower roasting for 4 hours, denoted as AC-1;

[0035] Add the roasted beta zeolite AC-1 to 2000 g of a...

Embodiment 2

[0038] Take 200g of sodium-type β zeolite (same as above), beat with 2000g of deionized water, add 35g of ammonium chloride and 22.2ml of RECl 3Solution (RE 2 o 3 Concentration 270 grams / litre), heat up to 85 DEG C and exchange for 1.5 hours, filter and wash with deionized water, and roast under 550 DEG C and 100% water vapor for 3 hours to obtain β zeolite after rare earth exchange, water content 3% by weight, record for A-2;

[0039] Dissolve 15.7g of zirconium oxychloride in 200g of ethanol, then mix the obtained solution with rare earth-exchanged beta zeolite A-2 evenly, stir for 24 hours, dry at 100°C for 24 hours, and bake at 550°C in a nitrogen atmosphere for 3 Hour, obtain the beta zeolite AC-2 after roasting;

[0040] The beta zeolite AC-2 after above-mentioned roasting is joined in 1500g acid concentration and is the oxalic acid aqueous solution of 2.0mol / L, is heated up to 90 ℃ and continues to stir for 1 hour, then filters, washes with deionized water (the amoun...

Embodiment 3

[0043] Take 200g of sodium-type β zeolite (same as above), beat with 3000g of deionized water, add 30g of ammonium chloride and 33.4ml of RECl 3 Solution (RE 2 o 3 Concentration 270 grams / litre), be warming up to 80 ℃ and exchange 2 hours, filter and wash with deionized water, roast 2 hours under 500 ℃, 100% water vapor, obtain beta zeolite after rare earth exchange, water content 2% by weight, record for A-3;

[0044] Dissolve 28.3g of zirconium isopropoxide in 200g of ethanol, then mix the above solution with the obtained rare earth-exchanged β zeolite A-3, leave it to stand for 12 hours, and then dry it; Hours, the zeolite beta after roasting was obtained, denoted as AC-3;

[0045] The beta zeolite AC-3 after above-mentioned roasting is joined in 1000g acid concentration and is the hydrochloric acid aqueous solution of 0.5mol / L, is stirred at 80 ℃ for 3 hours, then filters, washes with deionized water (the amount of washing water is 20% of the molecular sieve dry weight)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com