Green technology for preparing n-valeric acid from low-purity n-valeraldehyde by air oxidation

A technology of air oxidation and n-valeraldehyde, applied in the preparation of organic compounds, carboxylate preparation, organic chemistry, etc., can solve the problems of high cost of raw materials, and achieve the effects of high selectivity, less side reactions, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

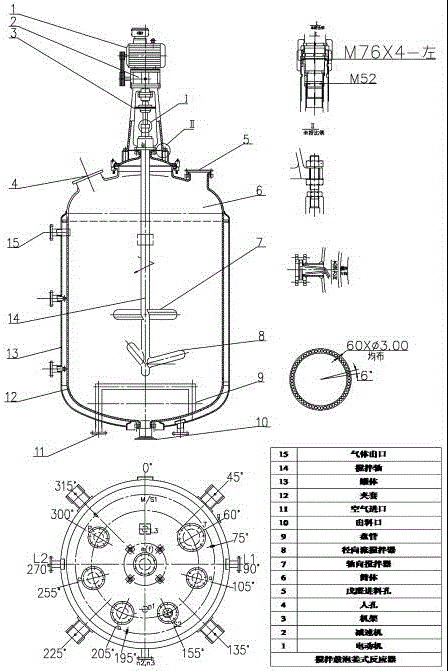

Image

Examples

Embodiment 1

[0017] Preparation of n-valeric acid in the laboratory: In a self-made bubbling reactor with an inner diameter of 46 mm and a length of 150 cm with a jacket, the n-valeraldehyde was directly oxidized by air to prepare n-valeric acid. By using a temperature-controllable circulating water pump to adjust the internal temperature of the bubbling reactor, the internal temperature of the reactor is kept constant. Air is bubbled in from below the bubble column. Weigh 100 g of 93.8% n-valeraldehyde and add it into a bubbling reactor with glass spring packing, use an air compressor to blow air in at a rate of 700 mL / min, control the reaction temperature at 80 °C, and track it with gas chromatography reaction. After reacting for 8 h, samples were taken for gas chromatography test, and the content of n-valeric acid was 94.5%, the conversion rate of n-valeraldehyde was 99.3%, and the selectivity was 98.5%.

Embodiment 2

[0019] The difference from Example 1 is that hydrogen peroxide is used as the oxidizing agent instead. Weigh 100 g of 93.8% n-valeraldehyde and add it into a 500mL reaction bottle. According to the molar ratio of n-valeraldehyde and hydrogen peroxide at 1:2, add 30% hydrogen peroxide dropwise. The reaction temperature is controlled at 80°C and the reaction time is controlled at After 8 h, the reaction was followed by gas chromatography. The result obtained by the reaction of Example 2: the conversion rate of n-valeraldehyde is 30%, the content of n-valeric acid is 23%, and the impurity content is high.

Embodiment 3

[0021] The difference from Embodiment 1 lies in: workshop scale-up. Weigh 600 kg of 93.8% n-valeraldehyde and add it into a stirred bubbler reactor, use an air compressor to blow air at a rate of 1500 L / min, control the reaction temperature at 80 °C, and use gas chromatography to track the reaction. After reacting for 20 h, samples were taken for gas chromatography test, and the content of n-valeric acid was 94.3%, the conversion rate of n-valeraldehyde was 97.5%, and the selectivity was 99.0%. Take 500 kg of the reaction solution for vacuum distillation to purify n-valeric acid, and collect fractions at 118-120°C. Obtain 22 kg of cuts with 75.1% n-valeric acid content, 434 kg of cuts with more than 98% n-valeric acid content, 35 kg of raffinate with 80.2% n-valeric acid content at the bottom of the still, and a single rectification with a purity of more than 98% n-valeric acid The acid yield was 86.8%. The components below 98% can be combined for secondary distillation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com