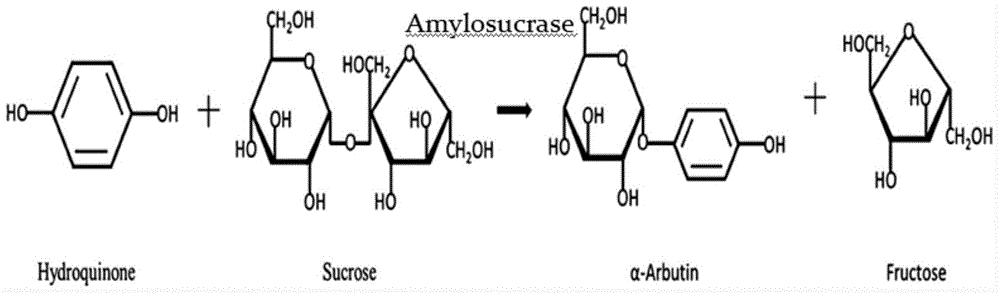

Gene engineering bacteria producing alpha-arbutin and construction method and application of gene engineering bacteria

A technology that encodes genes and purposes, applied in genetic engineering, microorganism-based methods, applications, etc., can solve the problems of only 83% conversion rate, toxicity, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the construction of the genetically engineered bacteria that produces α-arbutin

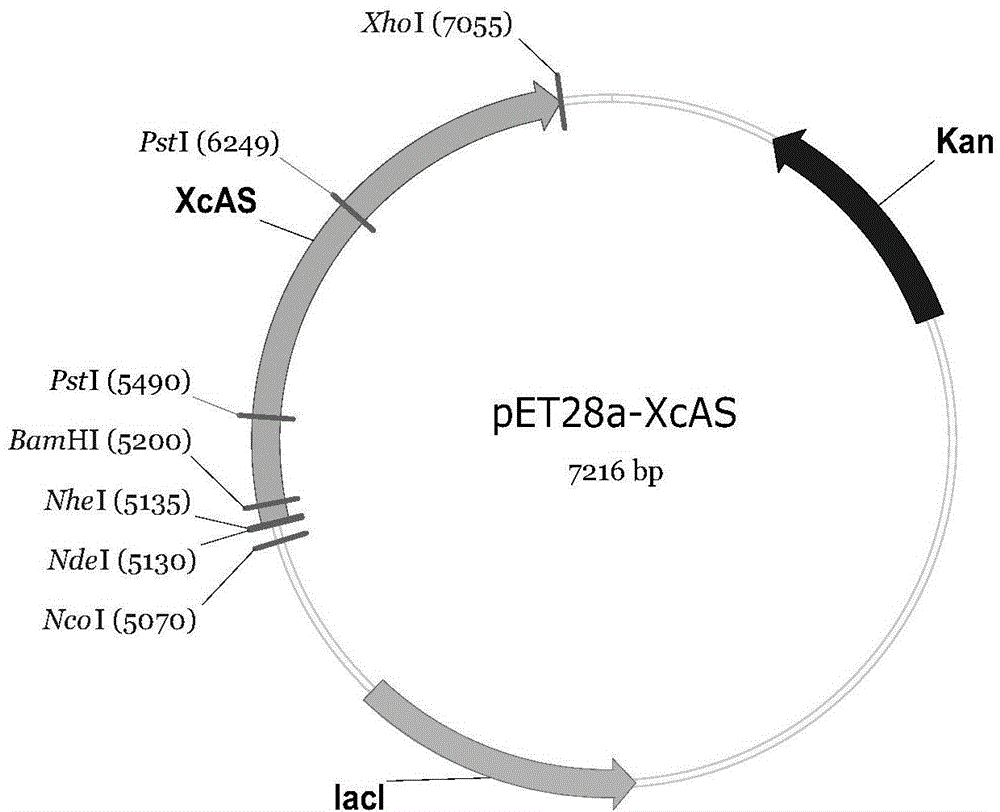

[0041] 1. Construction of a recombinant plasmid expressing amylosucrase derived from Xanthomonas campestris

[0042] In order to amplify the amylosucrase (Amylosucrase) gene XcAS derived from Xanthomonas campestris, design a pair of primers, the upstream primer is: GTGCCGCGCGGCAGCCATATG GCTAGC ATGATCGCTTCCTCCCCCATCG and downstream primer CAGTGGTGGTGGTGGTGGTG CTCGAG TCAACGACGCTGCAACCAGCGCAC.

[0043] Taking Xanthomonas campestris CGMCC 1.3408 genomic DNA as template, carry out PCR amplification with upstream primer and downstream primer, obtain the PCR amplification product that size is 1914bp, through sequencing, it is amylosucrase gene (Amylosucrase), The nucleotide sequence is sequence 1 in the sequence listing.

[0044] The PCR amplified product with a size of 1914bp was digested with NheI and XhoI, and the obtained digested product was ligated with the pET28a vector ...

Embodiment 2

[0059] The preparation of embodiment 2, α-arbutin

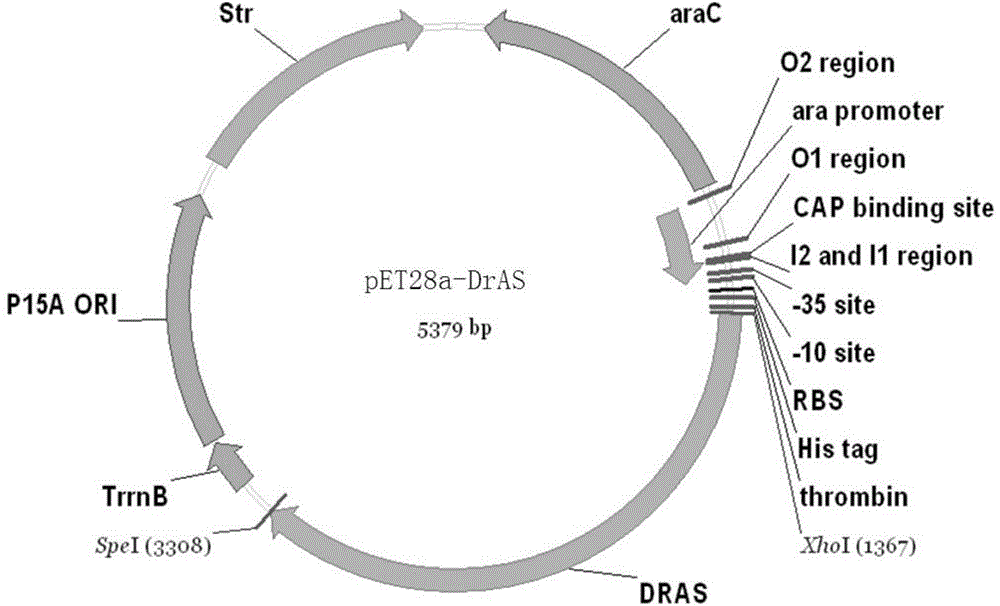

[0060] The genetically engineered bacteria pET28a-XcAS / BL21 obtained in Example 1 and the control bacteria pET28a-DrAS / BL21 are used as catalysts to produce α-arbutin, and the ability of these two strains of bacteria to produce α-arbutin in whole cell transformation is compared size, as follows:

[0061] 1. Preparation of α-arbutin

[0062] 1) Cultivate pET28a-XcAS / BL21 in liquid 2YT medium containing 80 μg / mL ampicillin at 37°C until the OD is 0.6, then add 0.2mM IPTG for induction, induce at 37°C for 10 hours, collect the induced products, and store at 4°C, Centrifuge at 8000 rpm for 15 minutes to collect the cells.

[0063] The above bacteria (i.e. cells), sucrose, hydroquinone, V C , TritonX-100 was added to Tris-HCl Buffer with a concentration of 100mM and a pH value of 7.0 and mixed to obtain a mixed solution; wherein, the cell concentration was 10g / L (wet weight), the concentration of sucrose was 1M, and the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com