Method of recovering silver from low-silver smelting slag

A smelting slag, lower technology, applied in the field of non-ferrous metallurgy and secondary resource recovery, can solve the problems of reducing the direct yield of gold and silver, the large amount of low-silver smelting slag, and the difficulty of gold and silver, so as to save resources , high recovery rate, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

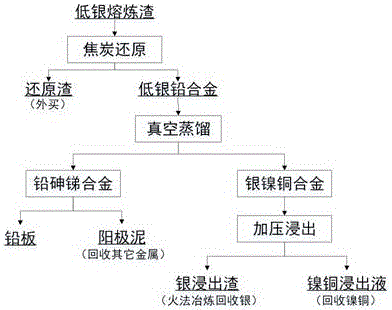

Embodiment 1

[0018] A method for recovering silver from low-silver smelting slag, comprising the following steps: adding coke accounting for 6% of the mass fraction of silver smelting slag in an electric furnace to reduce the silver smelting slag, the reduction temperature is 1200°C, and the reduction time is 3 hours to obtain gold-containing slag. Lead alloys with low silver content, lead, arsenic, antimony, copper, and nickel are reduced to simple substances, and form lead alloys with a small amount of gold and silver, and silicon, sodium, and some unreduced lead exist in the form of oxides in the reduced in the slag. Put the lead alloy in a vacuum furnace, and then control the vacuum degree to 5Pa and vacuum distillation for 2 hours at a temperature of 1000°C. The lead, arsenic, antimony, and bismuth in the lead alloy will volatilize into the volatiles to form a lead-arsenic-antimony alloy, nickel , copper, silver, gold and part of the non-volatile antimony and tellurium enter the resid...

Embodiment 2

[0020] A method for recovering silver from low-silver smelting slag, comprising the following steps: adding coke accounting for 4% of the mass fraction of silver smelting slag in an electric furnace to reduce the silver smelting slag, the reduction temperature is 1200°C, and the reduction time is 3 hours to obtain gold-containing slag. Lead alloys with low silver content, lead, arsenic, antimony, copper, and nickel are reduced to simple substances, and form lead alloys with a small amount of gold and silver, and some unreduced lead, silicon, and sodium exist in the form of oxides in the reduced in the slag. Put the lead alloy in a vacuum furnace, and then control the vacuum degree to 1Pa and vacuum distillation for 2 hours at a temperature of 1050°C. The lead, arsenic, antimony, and bismuth in the lead alloy will volatilize into the volatiles to form a lead-arsenic-antimony alloy, nickel , copper, silver, gold and part of the non-volatile antimony and tellurium enter the resid...

Embodiment 3

[0022] A method for recovering silver from low-silver smelting slag, comprising the following steps: adding coke accounting for 5% of the mass fraction of silver smelting slag in an electric furnace to reduce the silver smelting slag, the reduction temperature is 1200°C, and the reduction time is 3 hours to obtain gold-containing slag. Lead alloys with low silver content, lead, arsenic, antimony, copper, and nickel are reduced to simple substances, and form lead alloys with a small amount of gold and silver, and some unreduced lead, silicon, and sodium exist in the form of oxides in the reduced in the slag. Put the lead alloy in a vacuum furnace, and then control the vacuum degree to 10Pa and vacuum distillation for 2 hours at a temperature of 1050°C. The lead, arsenic, antimony, and bismuth in the lead alloy will volatilize into the volatiles to form a lead-arsenic-antimony alloy, nickel , copper, silver, gold and part of the non-volatile antimony and tellurium enter the resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com