Manufacturing method and temperature control system of perforated plug of seamless steel pipe

A technology of perforated plugs and manufacturing methods, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of excessive alcohol, increased cost, waste of resources, etc., and achieve less consumption of nitrogen and alcohol, good Forgeable performance, the effect of short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

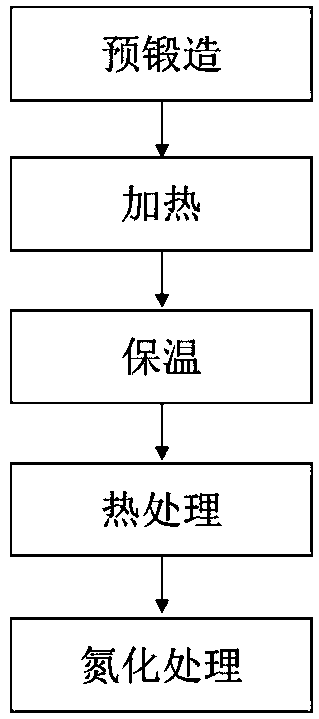

[0014] In the first embodiment of the present invention, a method for manufacturing a seamless steel pipe perforated plug is provided, see the attached figure 1 , including the following steps:

[0015] Step 1, pre-forging, heating the steel ingot to 150-200°C, and forging it for 5 minutes.

[0016] The steel ingot is made of improved 20CrNi4 material. The chemical composition of the original 20CRNI4 is (by weight): carbon C: 0.10-0.17, silicon Si: 0.17-0.37, manganese Mn: 0.30-0.60, sulfur S: allowable residual content ≤ 0.035, phosphorus P: allowable residual content ≤ 0.03, chromium Cr: 0.60~0.90, nickel Ni: 2.75~3.15, copper Cu: the allowable residual content is ≤0.030. A small amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com