A kind of crystalline silicon solar cell and its preparation method

A technology of solar cells and crystalline silicon, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of increased battery series resistance, decreased fill factor, and damaged passivation layer, and achieves increased open circuit voltage, Isc, and The effect of increasing the light path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

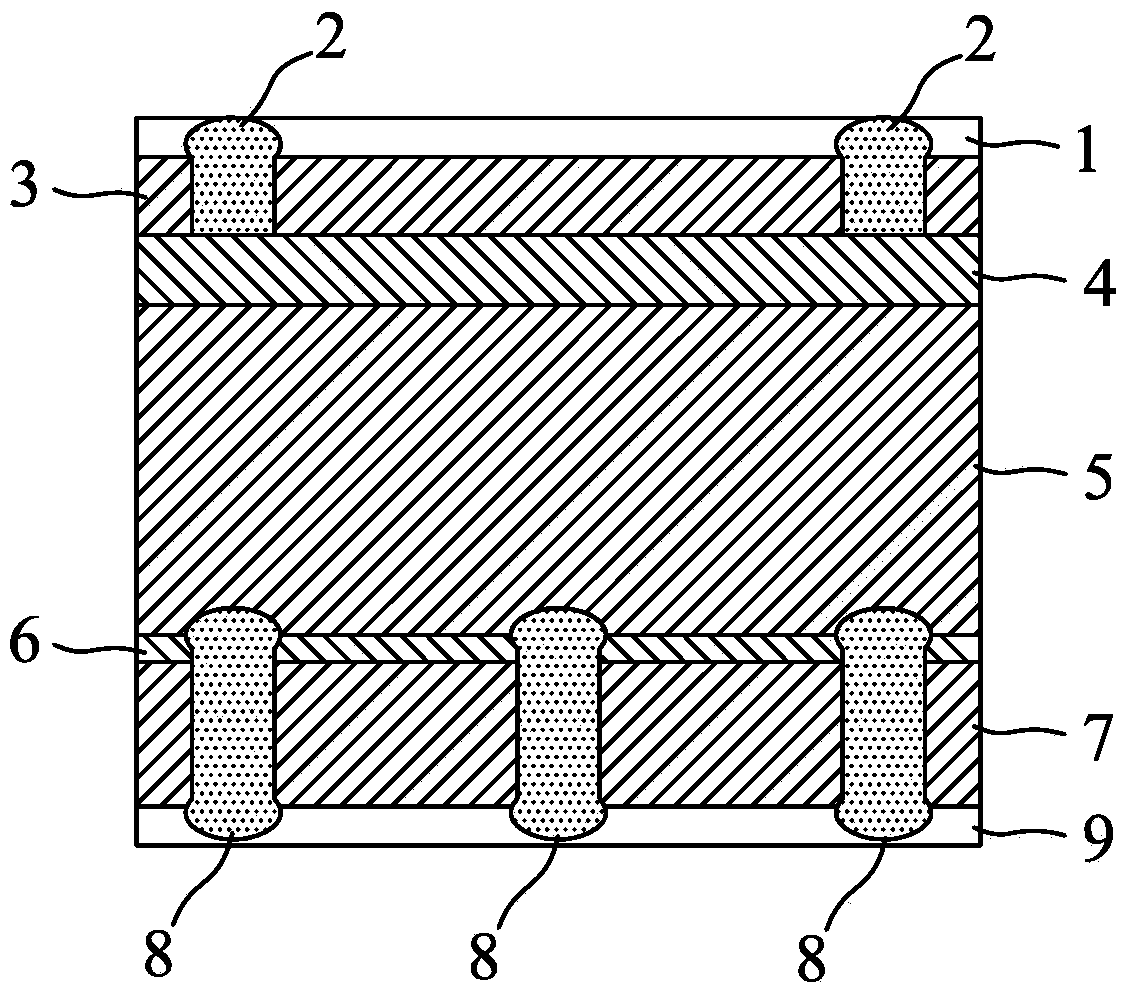

[0037] The present invention also provides a method for preparing the above-mentioned crystalline silicon solar cell, which specifically includes the following steps:

[0038] S1. Provide a silicon substrate with a diffusion layer on the light-facing surface, the silicon substrate is a P-type polycrystalline silicon-silicon substrate, and a P-type zinc oxide is deposited on the backlight surface of the silicon substrate to form a conductive medium layer;

[0039] S2. Prepare a protective layer on the conductive medium layer, and then prepare an aluminum back field on the protective layer, the aluminum back field penetrates the conductive medium layer and the protective layer, and is in contact with the silicon substrate and the conductive medium layer at the same time;

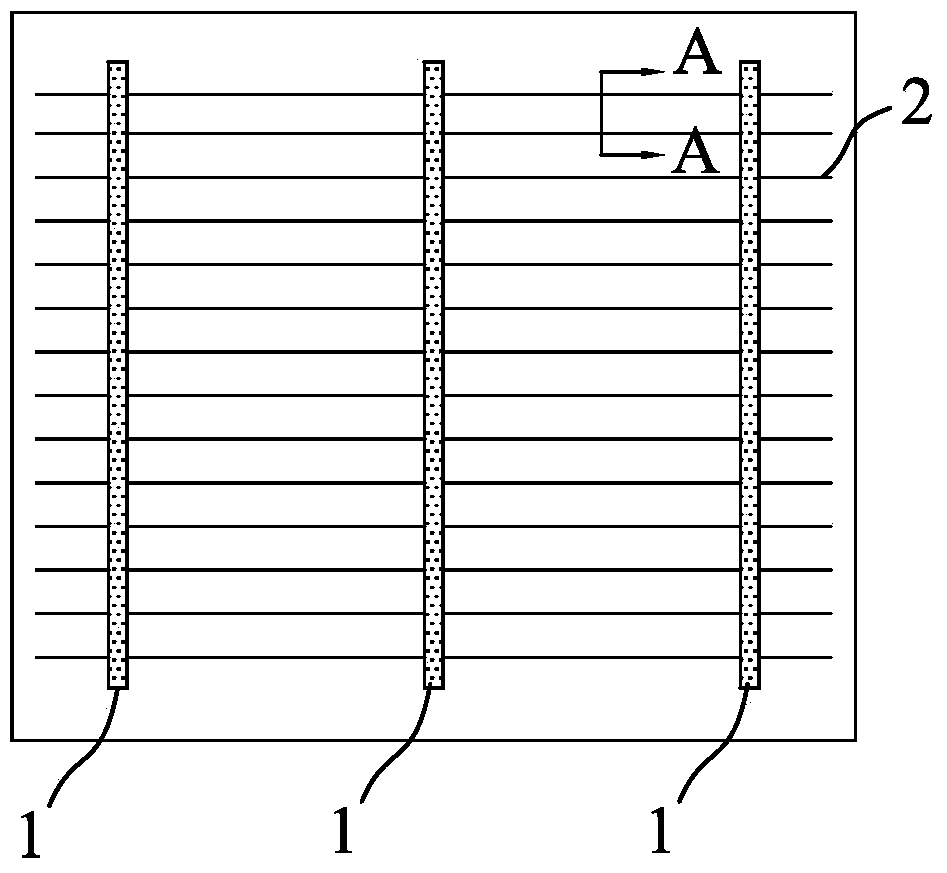

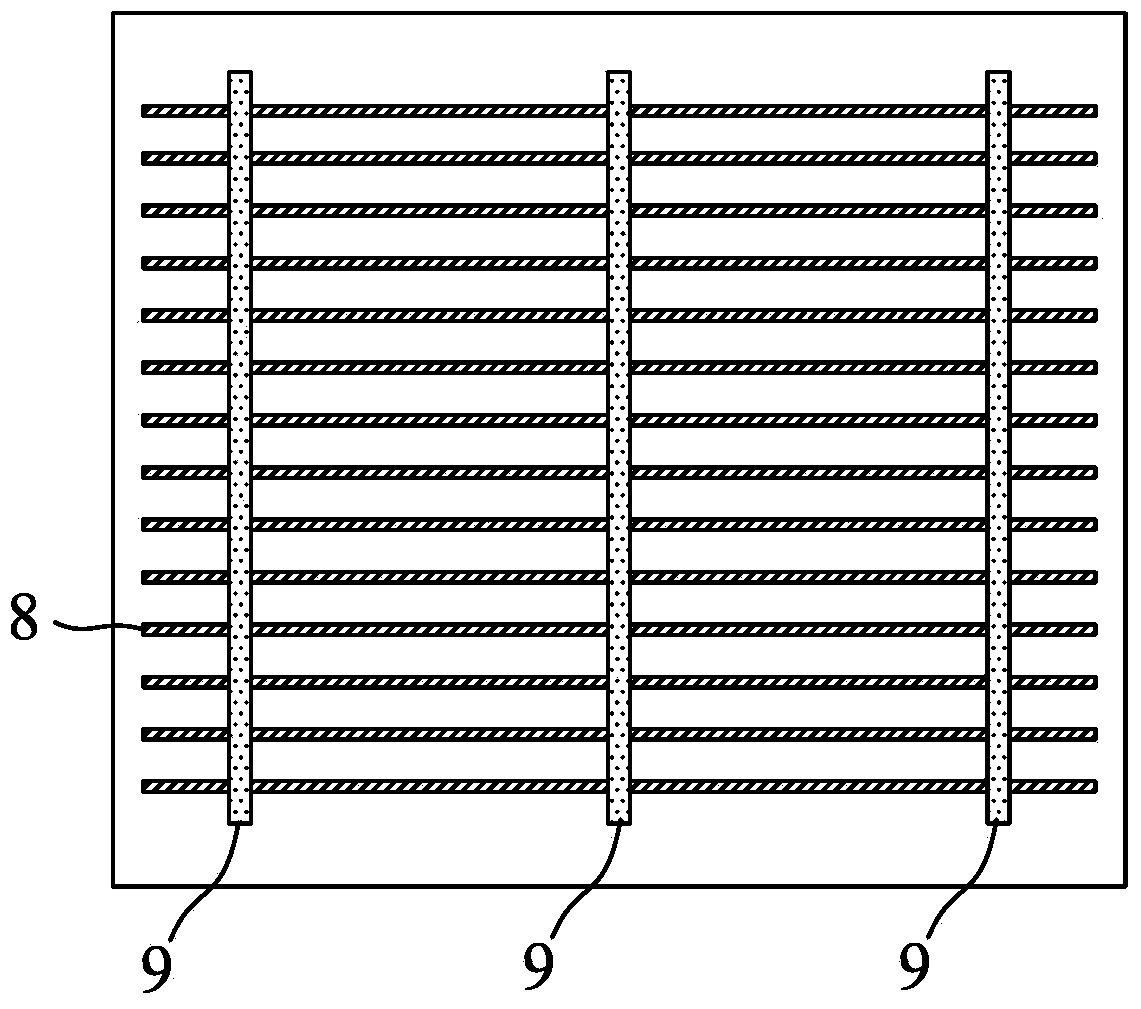

[0040] S3. On the protective layer on the backlight surface of the silicon substrate, prepare electrode grid lines on the backlight surface that are in contact with the aluminum back field, and prepare electrode ...

Embodiment 1

[0069] This embodiment is used to illustrate the crystalline silicon solar cell and its preparation method disclosed in the present invention.

[0070] 1. Preparation of silicon wafers before coating

[0071] The specification of the P-type polycrystalline silicon wafer used is: 156mm×156mm, and the thickness is 200μm. After the silicon wafer is textured, diffused and etched, the back of the silicon wafer is polished to obtain a silicon substrate with a diffusion layer on the surface.

[0072] 2. Preparation of P-type zinc oxide conductive dielectric layer

[0073] Solay Tech InPassion ALD 3600 atomic layer deposition equipment produced in the Netherlands was adopted, and dimethyl zinc, ammonia gas, trimethyl aluminum and deionized water were used as the zinc source, nitrogen source, aluminum source and oxygen source required for deposition, and dimethyl The molar ratio of base zinc: ammonia: trimethylaluminum: deionized water is 1:2:0.05:4. The temperature of the silicon su...

Embodiment 2

[0087] This embodiment is used to illustrate the crystalline silicon solar cell and its preparation method disclosed in the present invention.

[0088] Change the deposition time of the P-type zinc oxide conductive medium layer in embodiment 1 step 2 to 60 seconds, and the deposition thickness is 90-95nm. The resistivity of the conductive medium layer is tested to be 0.0453Ωcm. All the other processes and other steps are carried out Example 1 is the same.

[0089] The obtained crystalline silicon solar cell is denoted as S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com