Nitrogen-doped graphene-metal oxide nanocomposite material as well as preparation method and application thereof

A technology of nitrogen-doped graphene and nanocomposite materials, applied in the field of nanomaterials, can solve the problems of large particle size, uneven growth of metal oxide particles, low nitrogen doping content, etc., and achieve uniform particle size and operability And the effect of good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation:

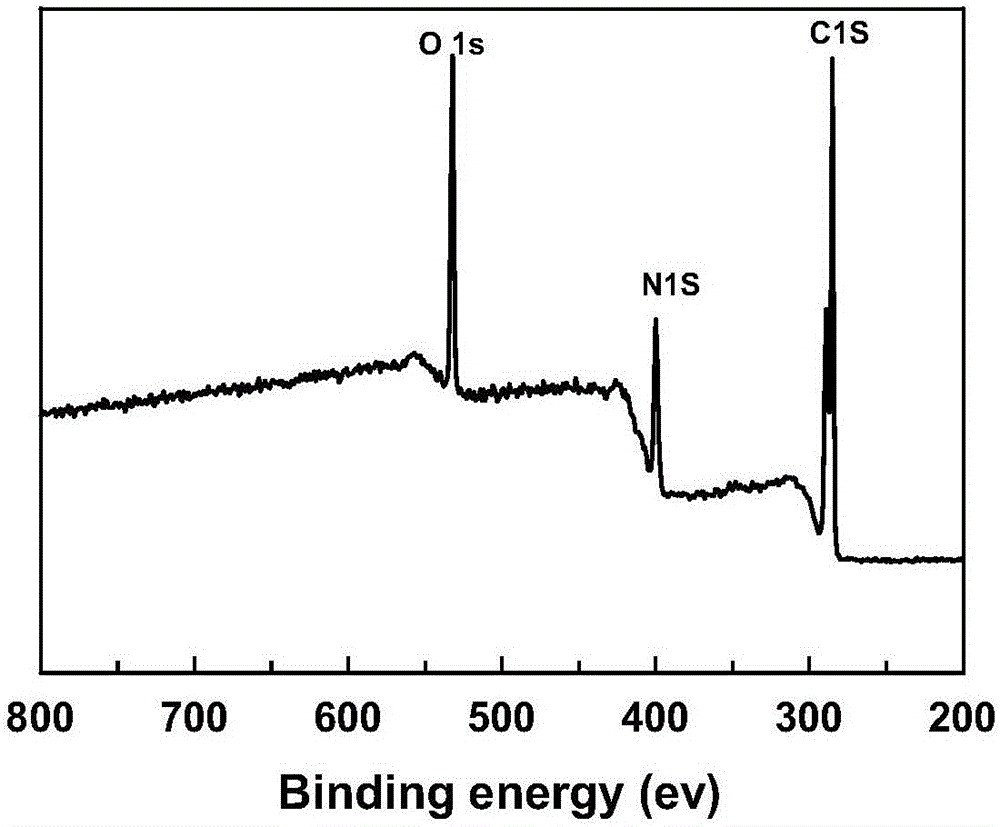

[0042] S1. Measure 200ml 0.5mg / ml graphene oxide aqueous solution and place it in a 250ml triangular beaker, then add 8ml 50wt% cyanamide aqueous solution, stir evenly, react at 90°C for 24h, filter the reaction product with deionized water Washing and drying to obtain nitrogen-doped graphene.

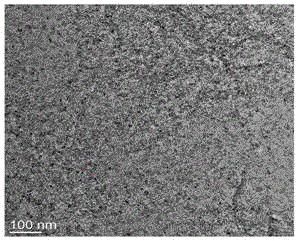

[0043] S2. Weigh 30mg of nitrogen-doped graphene, add it to 160ml of absolute ethanol for ultrasonic dispersion, and then take 0.07mmol of TiCl 4 , dissolved in 8ml of absolute ethanol, added to the dispersed nitrogen-doped graphene solution, magnetically stirred until it was uniformly dispersed, slowly added 4ml of deionized water, and then transferred the dispersion to the reaction kettle for 120 ℃ reaction 2h.

[0044] S3. The reaction product is naturally cooled, filtered, washed, and dried at 60° C. to obtain a nitrogen-doped graphene-titanium dioxide nanocomposite material.

[0045] 2. Characterization and performance testing:

[0046] Performance tes...

Embodiment 2

[0051] S1. Weigh 100 mg of partially reduced graphene and place it in a 250 ml conical beaker, add 200 ml of deionized water, and ultrasonically disperse evenly. Then add 4 g of melamine, stir evenly, react at 200° C. for 0.5 h, filter the reaction product with suction, wash with deionized water, and dry to obtain nitrogen-doped graphene.

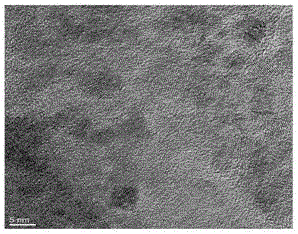

[0052] S2. Weigh 30mg of nitrogen-doped graphene, ultrasonically disperse it into 160ml of absolute ethanol, and then take 0.7mmol of SnCl 4 , dissolved in 8ml of absolute ethanol, then added to the dispersed nitrogen-doped graphene solution, magnetically stirred until it was uniformly dispersed, then slowly added 4ml of deionized water, and then transferred the dispersion to the reaction kettle Reaction at 120°C for 2h.

[0053] S3. The reaction product is naturally cooled, then filtered, washed, and dried at 100° C. to obtain a solvothermally synthesized nitrogen-doped-tin dioxide nanocomposite material.

[0054] After testing, the nitr...

Embodiment 3

[0056] S1. Weigh 100 mg of partially reduced graphene and place it in a 250 ml conical beaker, add 200 ml of deionized water, and ultrasonically disperse evenly. Then add 4 g of urea, stir evenly, react at 90° C. for 48 hours, filter the reaction product with suction, wash with deionized water, and dry to obtain nitrogen-doped graphene.

[0057] S2. Weigh 30mg of nitrogen-doped graphene and ultrasonically disperse it into 160ml of absolute ethanol, then take 0.3mmol of FeCl 3 ·6H 2 O, dissolved in 8ml of absolute ethanol, then added to the dispersed nitrogen-doped graphene solution, magnetically stirred until it was uniformly dispersed, then slowly added 4ml of deionized water, and then transferred the dispersion to the reaction kettle React at 120°C for 2h.

[0058] S3. The reaction product is naturally cooled, then suction filtered, washed, and dried at 80° C. to obtain a solvothermally synthesized nitrogen-doped graphene-ferric oxide nanocomposite material.

[0059] Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com