Cured meat processing method

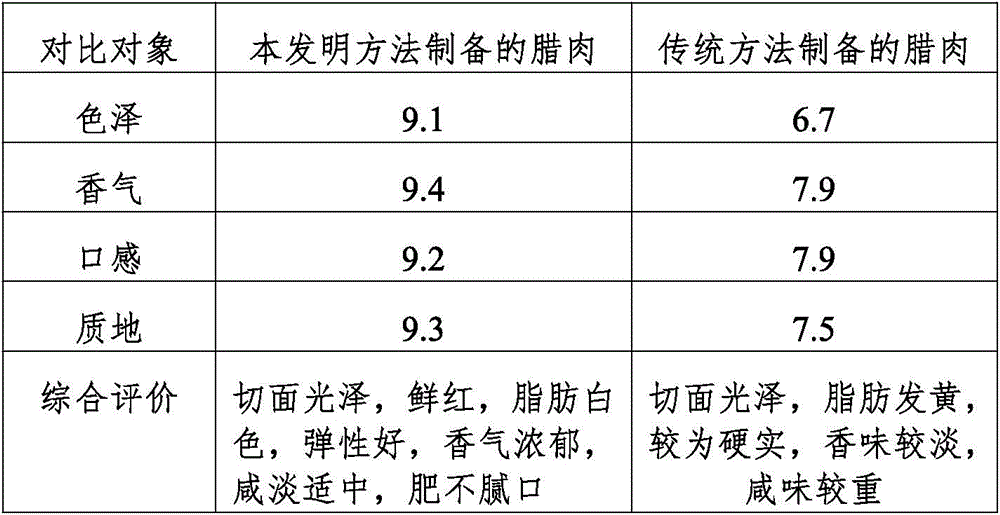

A technology for bacon and pork, applied in the preservation of meat/fish, preservation of meat/fish with chemicals, preservation of meat/fish through radiation/electrical treatment, etc., can solve the problems of restricting the export of bacon, long smoking time, air pollution, etc. problems, to achieve the effect of improving the taste and nutritional content, rich and lasting aroma, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for processing bacon, comprising the following steps:

[0030] (1) Preparation of spices: it consists of the following raw materials in parts by weight: cypress 1kg, cinnamon 4kg, vetiver 3kg, grass fruit 4kg, nutmeg 6kg, tangerine peel 2kg, notoginseng 1kg, astragalus 3kg, Codonopsis 2kg; Mix the above raw materials to obtain a mixture, add 2.5% water of the mixture, decoct in rapid fire before boiling, simmer for 30 minutes after boiling, filter to obtain the first filtrate; add 1.5% water of the filter residue, decoct for 80min with low heat, filter , Mix the two filtrates, and concentrate to 1 / 2 at 100°C to obtain the fragrance.

[0031] (2) Processing of raw meat: select pigs that have passed the quarantine inspection and have grown for one year. After slaughtering, the pork is divided into 500g strips or blocks, and the pork is sterilized.

[0032] (3) Pork marinating: For every 100kg of raw meat, use 4kg of salt, 1.3kg of rock sugar, 0.8kg of white wine...

Embodiment 2

[0040] A method for processing bacon, comprising the following steps:

[0041] (1) Preparation of spices: it consists of the following raw materials in parts by weight: cypress 2kg, cinnamon 8kg, vetiver 7kg, grass fruit 10kg, nutmeg 13kg, tangerine peel 5kg, Panax notoginseng 6kg, astragalus 5kg, Codonopsis 7kg; Mix the above raw materials to obtain a mixture, add 3 times the water of the mixture, decoct in a rapid fire before boiling, decoct in a slow fire for 50 minutes after boiling, filter to obtain the first filtrate; add 2.2 times the water of the filter residue, and decoct in a slow fire for 100 minutes , Filtrate, mix the two filtrates, and concentrate to 1 / 2 at 120 ° C to obtain the fragrance.

[0042] (2) Processing of raw meat: select pigs that have passed the quarantine inspection and have grown for one year. After slaughtering, the pork is divided into 1000g strips or blocks, and the pork is sterilized.

[0043] (3) Pork marinating: For every 100kg of raw meat, ...

Embodiment 3

[0051] A method for processing bacon, comprising the following steps:

[0052] (1) Preparation of spices: it is composed of the following raw materials in parts by weight: cypress 1.5kg, cinnamon 6kg, vetiver 5kg, grass fruit 6kg, nutmeg 10kg, tangerine peel 3kg, Panax notoginseng 4kg, astragalus 4kg, Codonopsis 5kg; Take the above raw materials and mix them to get a mixture, add 2.8 times the water of the mixture, decoct in a rapid fire before boiling, decoct in a slow fire for 40 minutes after boiling, filter to get the first filtrate; add 2 times the water of the filter residue, and decoct in a slow fire After 90 minutes, filter, mix the two filtrates, and concentrate to 1 / 2 at 110°C to obtain the fragrance extract.

[0053] (2) Processing of raw meat: select the 1-year-old pigs that have passed the quarantine inspection, and after slaughtering, divide the pork into 800g strips or blocks, and then sterilize the pork.

[0054] (3) Pork marinating: For every 100kg of raw mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com