Preparation method of moxifloxacin-loaded electro-spinning film antibacterial dressing

A moxifloxacin and electrospinning technology, which is applied in the field of preparation of moxifloxacin-loaded electrospun membrane antibacterial dressings, can solve the problems of granulation tissue adhesion and scab, long wound healing period, and obvious scars, and achieve good biodegradation Sexuality and compatibility, promote wound healing, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a water bath at 80°C, stir the PVA with distilled water on a magnetic stirrer, fully swell and dissolve completely, and prepare PVA solutions with a concentration of 8%, 10%, 12% and 14%. It is found in the configuration that the PVA solution concentration is When it is 12%, the viscosity of the solution is more suitable for spinning, and the prepared spinning is less beaded and will not block the nozzle.

Embodiment 2

[0039] At room temperature, stir SA with distilled water on a magnetic stirrer, fully swell and dissolve completely, and prepare SA solutions with concentrations of 2%, 2.5% and 3%. Pipette 12% PVA with a volume ratio of 3:2 and the above-mentioned SA solutions of different concentrations, stir well, and spin on a spinning machine at room temperature. The results are listed in Table 1 below.

[0040] Table 1

[0041]

Embodiment 3

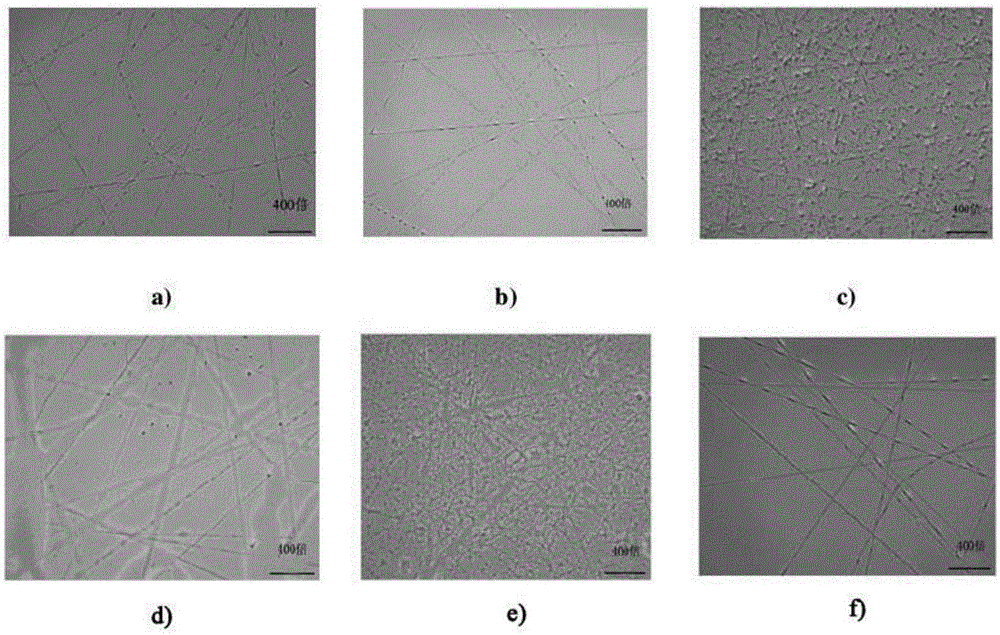

[0043] Weigh five portions of PVA and SA with a mass ratio of 9:1 and a total mass of 0.4g in parallel, accurately pipette 4ml of distilled water, place it in a water bath at 80°C, stir and dissolve fully on a magnetic stirrer, and add water after cooling and 1ml of DMSO, THF, DMF, and 1,2-propanediol organic solvents, fully stirred evenly at room temperature to prepare a spinning solution with a solvent volume ratio of 4:1, and spun on a spinning machine to investigate the effect of the solvent on the spinning solution. The influence of morphology, diameter and uniformity, the glass slides were then spun and observed under a microscope with a magnification of 400×.

[0044] Such as figure 1 The spinning diameters and beaded spinning numbers in a), b) and f) shown are similar, and the spinning surface is relatively smooth. But with chloroform: water as its viscosity of the spinning solution of solvent is bigger, easy to block nozzle; With 1,2-propanediol: water (v:v=4:1) is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com