Preparation method of nanomaterial-modified zeolite, and applications of zeolite in environment restoration

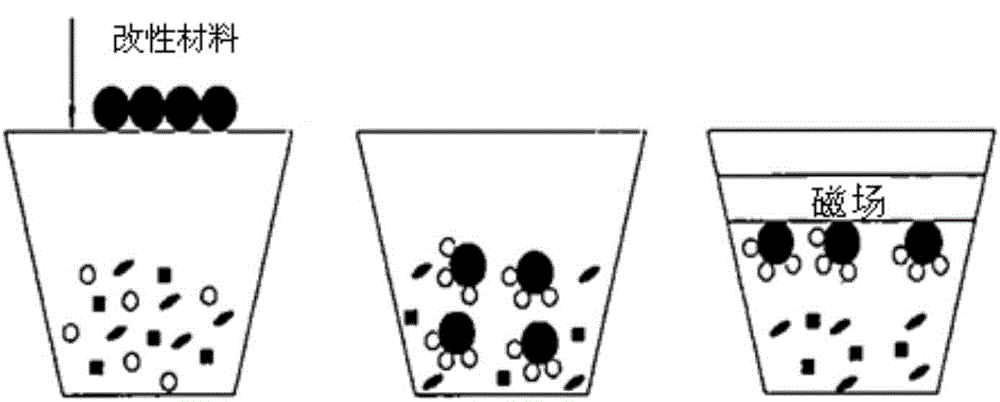

A technology for modifying zeolite and nanomaterials, which is applied in nanotechnology, chemical instruments and methods, and other chemical processes. Reduction and other issues, to achieve the effect of safe and reliable adsorption materials, easy industrial promotion, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

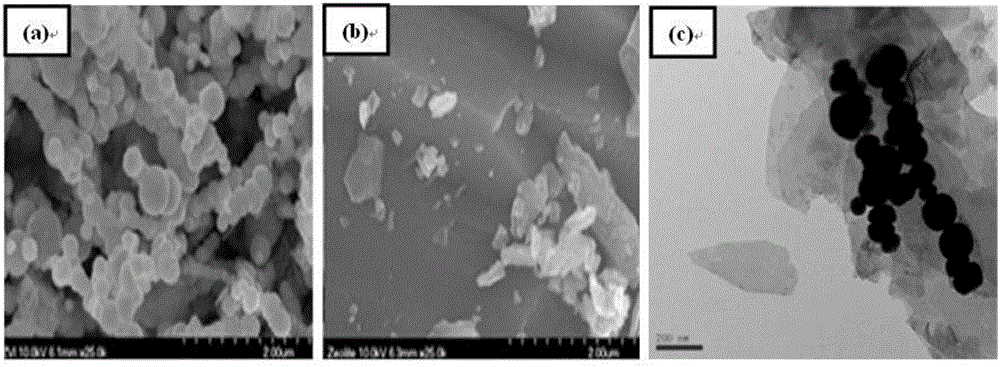

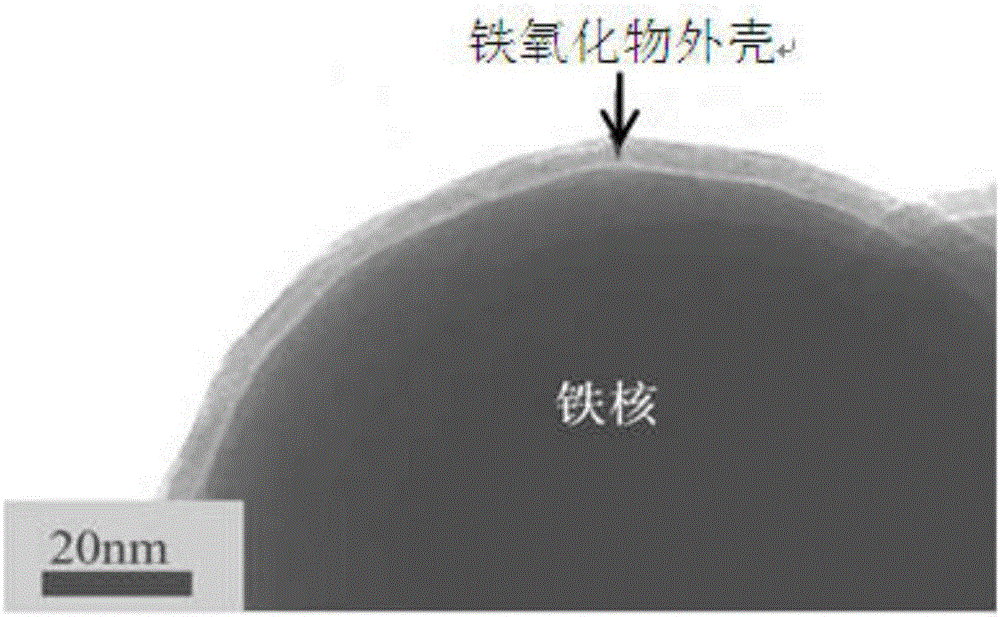

[0057] Embodiment 1, a kind of preparation method of nanomaterial modified zeolite, carries out following steps successively:

[0058] 1) 100 g of natural clinoptilolite was acid-washed with 1000 ml of 0.12M HCl, dried at 80° C. to constant weight, and passed through a 100-mesh sieve as a carrier.

[0059] 2) Weigh 100g of the carrier and add it to 2500ml of 0.24M FeCl 3 ·6H 2 O aqueous solution, adjust the pH of the gained suspension system to be 4.5 (using the HCl of 1M to adjust), ultrasonic (frequency is 53kHz, power is 500w) 30 minutes, then add the surfactant solution of 500ml and continue to stir (stirring speed is 2000r / min) 24 hours makes Fe 3+ Evenly adsorbed and wrapped on the inner and outer surfaces of natural clinoptilolite to obtain a mixed solution;

[0060] The above-mentioned surfactant solution is absolute ethanol.

[0061] That is, FeCl 3 ·6H 2 The volume ratio of O aqueous solution to surfactant solution is 5:1.

[0062] 3) Add 0.98M NaBH dropwise t...

Embodiment 2

[0069] Embodiment 2, a kind of preparation method of nanomaterial modified zeolite, carries out following steps successively:

[0070] 1) 100 g of natural clinoptilolite was acid-washed with 800 ml of 0.15M HCl, dried at 85° C. to constant weight, and passed through a 100-mesh sieve as a carrier.

[0071] 2) Weigh 100g of the carrier and add it to 1000ml of 0.28M FeCl 3 ·6H 2 In the O aqueous solution, adjust the pH of the suspension system to be 4.5, sonicate for 30 minutes, then add 100ml of surfactant solution and continue to stir for 28 hours to make Fe 3+ Evenly adsorbed and wrapped on the inner and outer surfaces of natural clinoptilolite to obtain a mixed solution;

[0072] The above-mentioned surfactant solution is an EDTA-2Na (disodium ethylenediaminetetraacetic acid) solution with a mass concentration of 5%.

[0073] That is, FeCl 3 ·6H 2 The volume ratio of O aqueous solution to surfactant solution is 10:1.

[0074] 3) Add 0.98M NaBH dropwise to the mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com