A kind of cellulose-based tio2/β-cd double network gel cage microsphere and its preparation method and application

A cellulose-based and cellulose technology, applied in the field of gel microspheres and its preparation, can solve the problems of high cost and non-recyclable use of adsorbents, and achieve good surface uniformity, long-term storage, and good water retention performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

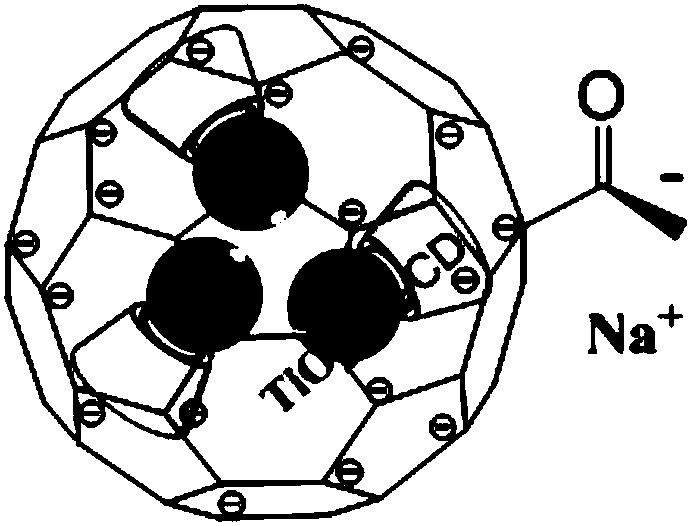

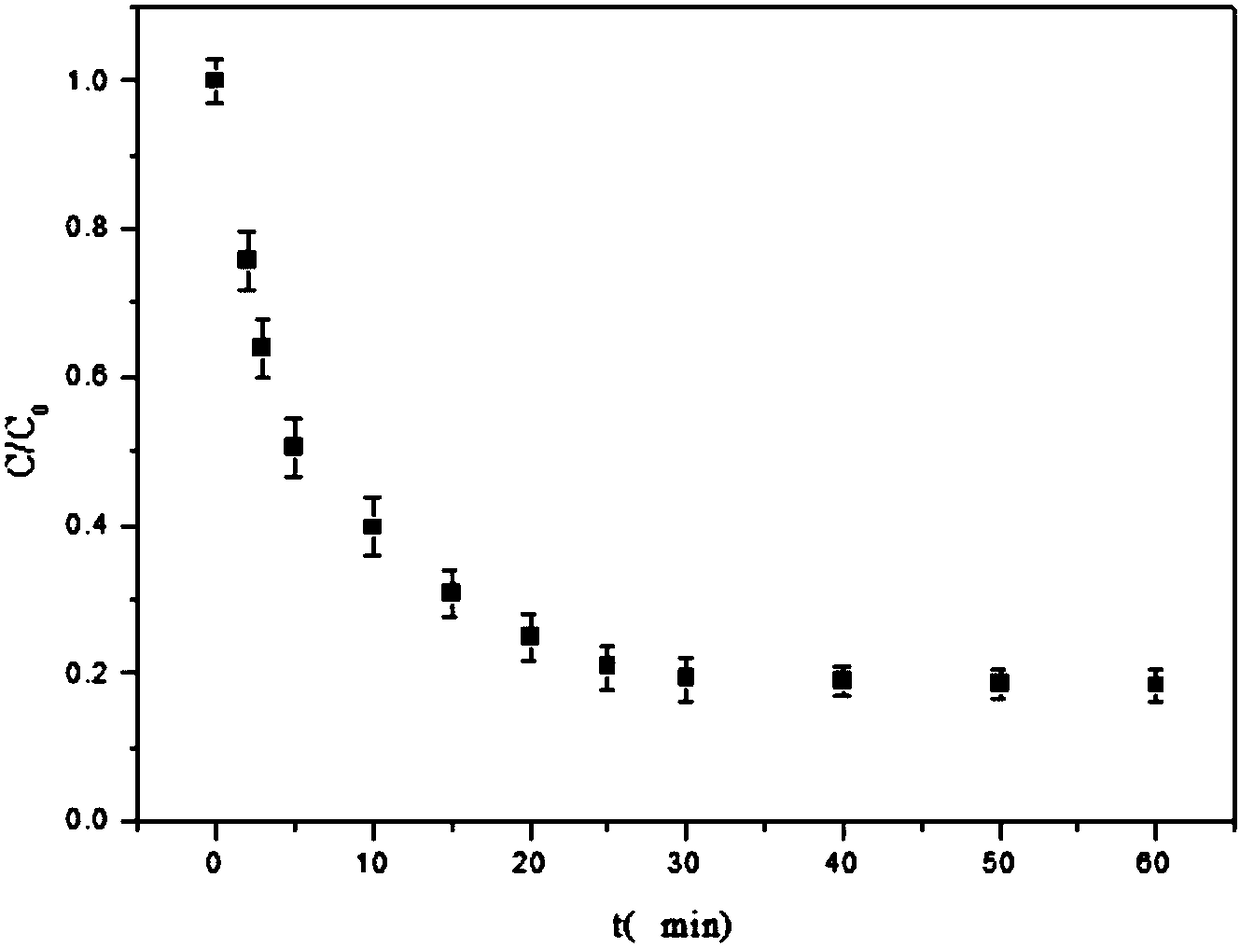

[0042] Specific implementation mode 1: In this implementation mode, cellulose-based TiO 2 / β-CD double network gel cage microspheres are composed of hydroxyethyl cellulose, carboxymethyl cellulose, crosslinking agent, initiator, TiO 2 / β-CD complex suspension and deionized water; wherein the mass ratio of hydroxyethyl cellulose and carboxymethyl cellulose is (6-8): (2-4), and the mass ratio of hydroxyethyl cellulose The volume ratio of mass to cross-linking agent is (0.6-0.8) g: (3-5) mL, and the volume ratio of hydroxyethyl cellulose to initiator is (0.6-0.8) g: (3-5) mL , the mass of hydroxyethyl cellulose and TiO 2 The volume ratio of / β-CD complex suspension is (0.6~0.8)g: (10~15)mL, the volume ratio of the mass of hydroxyethyl cellulose to deionized water is (0.6~0.8)g:( 10-20) mL.

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment is different from Embodiment 1 in that: the crosslinking agent is epichlorohydrin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the initiator is 10 mol / L NaOH solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com