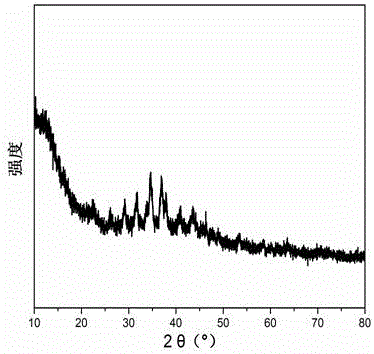

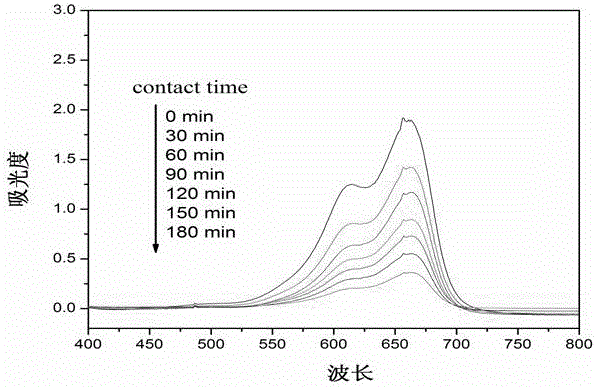

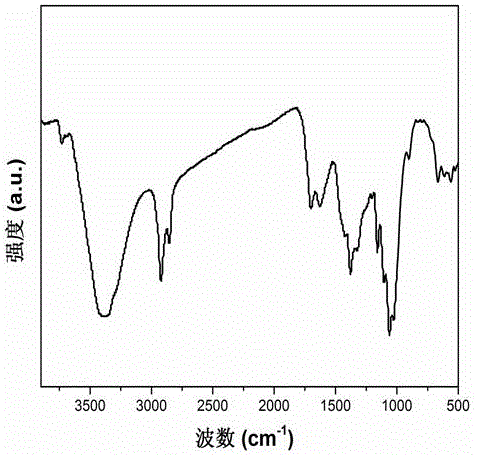

Preparation method of silver sulfide loaded radish derived carbon aerogel material

A technology for deriving carbon and aerogel, which is applied in the field of nanomaterials, can solve the problems of complex processing, increase production cost and application, and achieve the effects of simple equipment, abundant raw materials, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Peel the radish and cut it into a size of 2cm*3cm*4cm, put it into a reaction kettle and conduct a hydrothermal reaction at 180°C for 18h.

[0031] The material obtained by the reaction was first washed with distilled water, then soaked and washed twice with ethanol aqueous solution at 40°C to 45°C, then cooled to room temperature, and finally washed once with distilled water to obtain a biomass charcoal-based wet gel.

[0032] Weigh 0.02g of cetyltrimethylammonium chloride (CTAC) and dissolve it in 20mL of distilled water, ultrasonically shake it to dissolve completely, then add 12g of biochar-based wet gel and 0.025g of silver nitrate , reacted in a constant temperature water bath at 40°C to 45°C for 10 hours in the dark, and obtained a precipitate after the reaction—a carbon aerogel with silver chloride attached to the hole.

[0033] Then add 0.025g of sodium sulfide to 12g of the carbon aerogel with silver chloride attached to the holes, and carry out the metathesis...

Embodiment 2

[0036] Peel the radish and cut it into a size of 2cm*3cm*4cm, put it into a reaction kettle and conduct a hydrothermal reaction at 200°C for 18h.

[0037] The material obtained by the reaction was first washed with distilled water, then soaked and washed twice with ethanol aqueous solution at 40°C to 45°C, then cooled to room temperature, and finally washed once with distilled water to obtain a biomass charcoal-based wet gel.

[0038] Weigh 0.02g of CTAC and dissolve it in 20mL of distilled water, ultrasonically shake it to dissolve completely, then add 12g of biochar-based wet gel and 0.03g of silver nitrate, and keep it in a constant temperature water bath at 40°C to 45°C to avoid light After reacting for 10 hours, a precipitate was obtained after the reaction—a carbon aerogel with silver chloride attached to the pores.

[0039] Then add 0.03 g of sodium sulfide to 12 g of the carbon aerogel with silver chloride attached to the holes, and carry out the metathesis reaction un...

Embodiment 3

[0042] Peel the radish and cut it into a size of 2cm*3cm*4cm, put it into a reaction kettle and conduct a hydrothermal reaction at 180°C for 20h.

[0043] The material obtained by the reaction was first washed with distilled water, then soaked and washed twice with ethanol aqueous solution at 40°C to 45°C, then cooled to room temperature, and finally washed once with distilled water to obtain a biomass charcoal-based wet gel.

[0044] Weigh 0.03g of CTAC and dissolve it in 20mL of distilled water, ultrasonically shake to dissolve it completely, then add 13g of biochar-based wet gel and 0.025g of silver nitrate, and keep it in a constant temperature water bath at 40°C to 45°C to avoid light After reacting for 10 hours, a precipitate was obtained after the reaction—a carbon aerogel with silver chloride attached to the pores.

[0045] Add 0.025 g of sodium sulfide to 13 g of the carbon airgel with silver chloride attached to the holes, and carry out a metathesis reaction under da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com