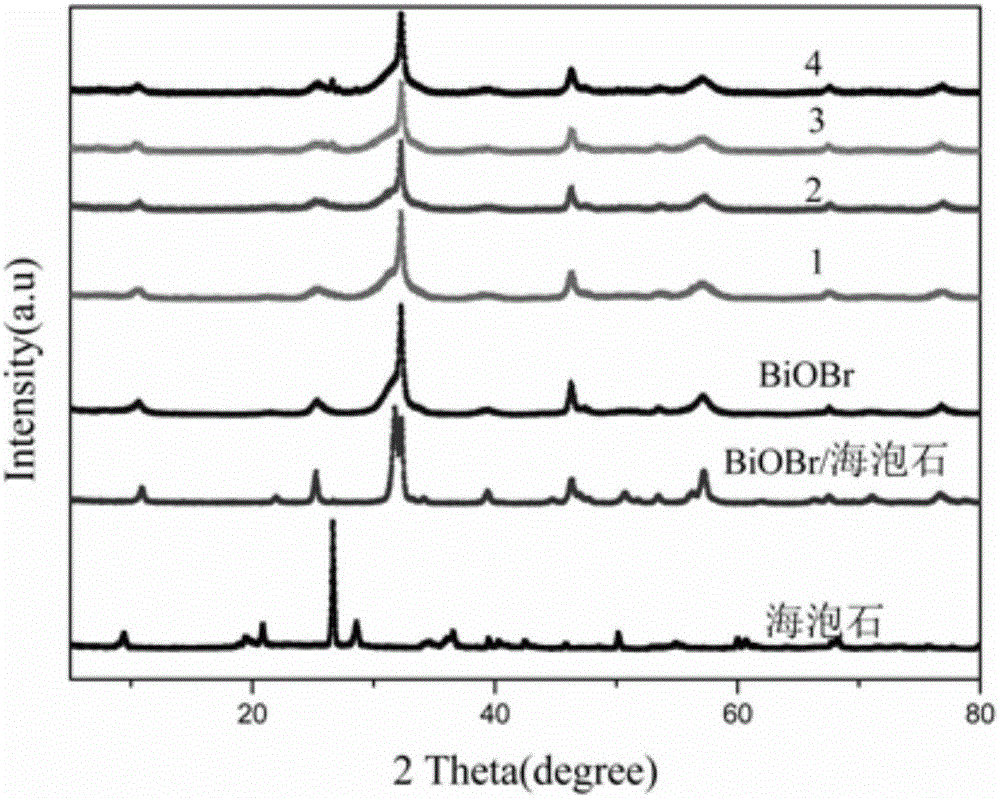

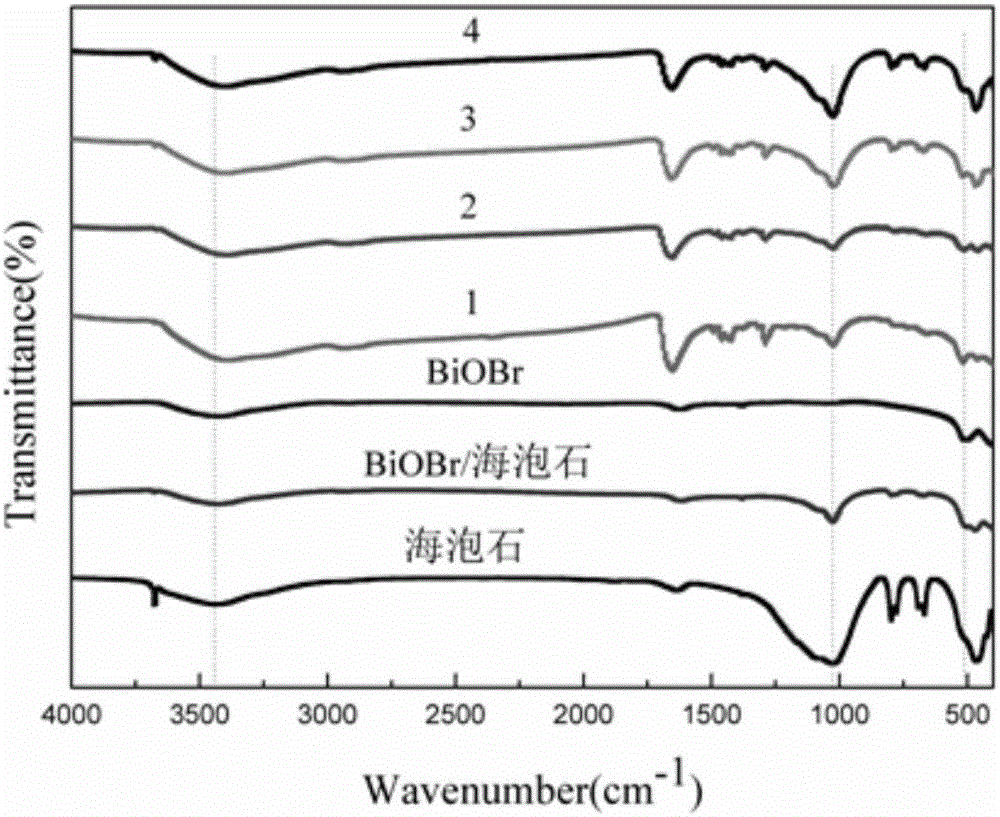

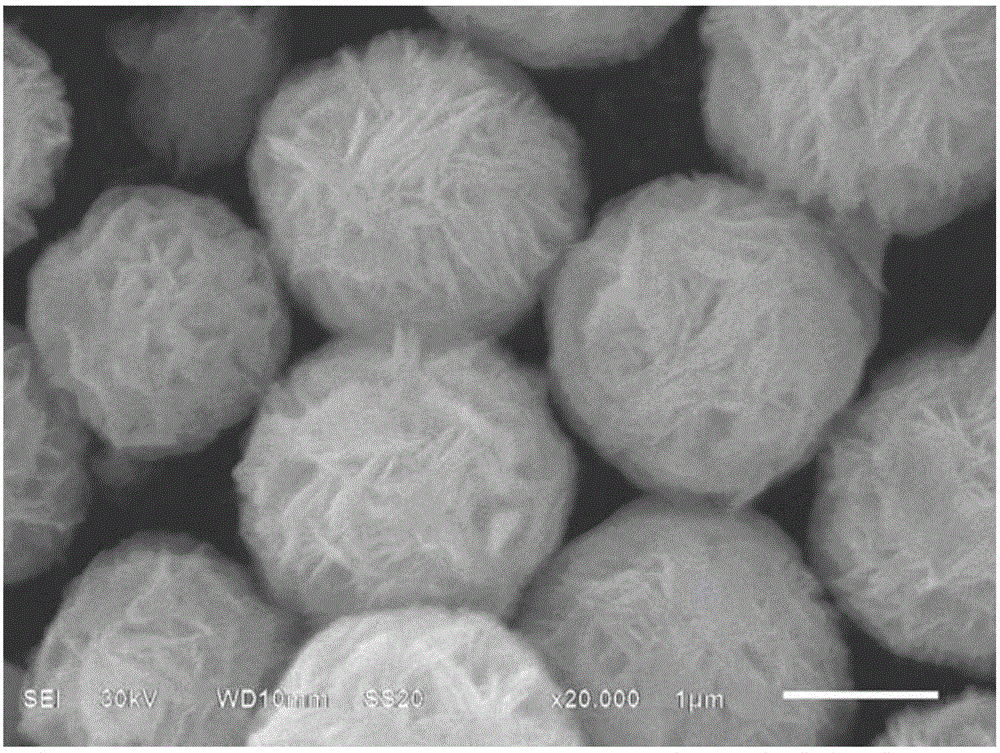

Method for PVP assisted preparation of flower-like BiOBr/sepiolite composite catalyst and application of composite catalyst

A technology of composite catalyst and sepiolite, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of no composite photocatalyst of sepiolite and BiOBr, so as to improve the photocatalytic ability , Good dispersibility, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Sepiolite pretreatment: Soak the raw sepiolite soil in distilled water, wash with distilled water several times, filter until the pH is neutral, dry in an oven, grind, and sieve for later use.

[0035] 2) Add the purified sepiolite to a concentration of 1.5mol L -1 hydrochloric acid solution, so that the solid-to-liquid ratio is 1g:7mL, soak, wash, suction filter, and dry.

[0036] 3) Calcining the acid-treated sepiolite at a rate of 5° C. / min to 400° C. for 3 hours, and passing through a 80-mesh sieve after cooling to obtain modified sepiolite.

[0037] 4) Weigh 25 mg of modified sepiolite and place it in 60 mL of ethylene glycol solvent, and disperse it by ultrasonication for 1 hour to obtain a suspension. Add 0.15gPVP and 3mmolBi(NO 3 ) 3 ·5H 2 O, stirred for 12h. Add an equal proportion of NH to the suspension 4 Br, stirred for 1 h, the solution was uniformly dispersed and transferred to a 100 mL reactor, reacted at 150 °C for 12 h, cooled to room temperatu...

Embodiment 2

[0039] 1)~3) The preparation method of modified sepiolite is the same as the preparation method of modified sepiolite in Example 1.

[0040] 4) Weigh 50 mg of modified sepiolite, place it in 60 mL of ethylene glycol solvent, and disperse it by ultrasonication for 1 hour to obtain a suspension. Add 0.15gPVP and 3mmolBi(NO 3 ) 3 ·5H 2 O, stirred for 12h. Add an equal proportion of NH to the suspension 4 Br, stirred for 1 h, the solution was uniformly dispersed and transferred to a 100 mL reactor, reacted at 160 °C for 12 h, cooled to room temperature, washed with ethanol and deionized water alternately, and dried at 60 °C to obtain a flower-shaped BiOBr / sepiolite composite catalyst.

Embodiment 3

[0042] 1) Sepiolite pretreatment: Soak the raw sepiolite soil in distilled water, wash with distilled water several times, filter until the pH is neutral, dry in an oven, grind, and sieve for later use.

[0043] 2) Add the purified sepiolite to a concentration of 1.2mol L -1 hydrochloric acid solution, so that the solid-to-liquid ratio is 1g:5mL, soak, wash, suction filter, and dry.

[0044] 3) The acid-treated sepiolite was calcined at a rate of 8°C / min at a temperature of 400°C for 2 hours, cooled and sieved with 80 meshes to obtain modified sepiolite.

[0045] 4) Weigh 100 mg of modified sepiolite and place it in 60 mL of ethylene glycol solvent, and disperse it by ultrasonication for 1 hour to obtain a suspension. Add 0.15gPVP and 3mmolBi(NO 3 ) 3 ·5H 2 O, stirred for 12h. Add an equal proportion of NH to the suspension 4 Br, stirred for 1 h, the solution was uniformly dispersed and transferred to a 100 mL reactor, reacted at 160 °C for 12 h, cooled to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com