Preparation method of hydrophobic mesoporous silicon and application of hydrophobic mesoporous silicon in preparing waterproof colored coating

A technology of mesoporous silicon and water medium, which is applied in pigment-containing coatings, water/sewage treatment, chemical instruments and methods, etc., can solve the problems that hydrophobic mesoporous silicon is not environmentally friendly and cannot be recycled, and achieves strong practical application value. , Product environmental protection, economic and social benefits are huge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

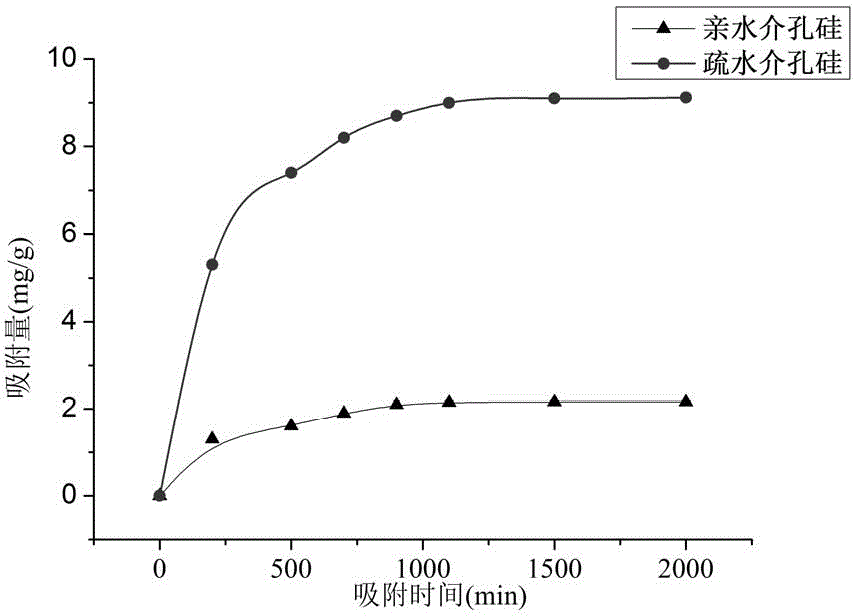

Image

Examples

Embodiment 1

[0014] In the specific implementation of the present invention, the preparation method of the hydrophobic mesoporous silicon is that 2g polyethylene oxide-polypropylene oxide-polyoxyethylene triblock copolymer (P123) is added to 70ml deionized water, Then add 12ml of hydrochloric acid with a mass concentration of 36%, 14mg of ammonium fluoride and 1.5g of mesitylene as a pore-enlarging agent, and stir at 40°C for 1 hour to form a mixed liquid; add 2g of ethyl orthosilicate and perfluorinated Octyltriethoxysilane 2g, continue to stir at 40°C for 12h, reflux at 95°C for 24h; suction filter to obtain a filter cake, wash the filter cake twice with water, and burn at 500°C for 8h to obtain a powdery hydrophobic media porous silicon.

Embodiment 2

[0016] In the specific implementation of the present invention, the preparation method of the hydrophobic mesoporous silicon is that 2.5g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) is added to 70ml deionized water , then add 11ml of hydrochloric acid with a mass concentration of 36%, 12mg of ammonium fluoride and 1.3g of mesitylene as a pore-enlarging agent, and stir at 35°C for 1 hour to form a mixed liquid; add 2.5g of ethyl orthosilicate and Perfluorooctyltriethoxysilane 2.5g, continue to stir at 40°C for 13h, reflux at 100°C for 12h; suction filter to obtain a filter cake, wash the filter cake twice with water, burn at 480°C for 9h to obtain a powder hydrophobic mesoporous silica.

Embodiment 3

[0018] In the specific implementation of the present invention, the preparation method of the hydrophobic mesoporous silicon is that 3.8g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) is added to 70ml deionized water , then add 12.5ml of hydrochloric acid with a mass concentration of 36%, 14mg of ammonium fluoride and 2.5g of mesitylene as a pore-enlarging agent, and stir at 45°C for 1 hour to form a mixed liquid; add 2.8g of ethyl orthosilicate to the mixed liquid and perfluorooctyltriethoxysilane 2.8g, continue stirring at 40°C for 14h, and reflux at 92°C for 24h; filter with suction to obtain a filter cake, wash the filter cake twice with water, and burn at 550°C for 6h to obtain a powder hydrophobic mesoporous silicon.

[0019] The application of the hydrophobic mesoporous silicon prepared by the methods described in Example 1, Example 2, and Example 3 in the preparation of waterproof color coatings is the same as the summary of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com