Erbium-doped medium-infrared light-emitting fluorophosphate glass and preparation method thereof

A technology of infrared luminescence and fluorochlorophosphate, which is applied in the field of erbium-doped mid-infrared luminescent fluorochlorophosphorus glass, which can solve problems such as poor thermal stability and chemical stability, inhomogeneous regions and crystallization, and increased glass scattering loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] According to 1-3 in Table 1 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh each raw material and mix evenly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace with a melting temperature of 1000 ° C, and clarify it for 15 pour the molten glass into the preheated mold; quickly move the glass into the muffle furnace that has been heated to near the annealing temperature (450°C), keep it warm for 4 hours, and then lower it to room temperature at a rate of 10°C / hour. Remove the glass sample after complete cooling.

[0033] The test results for this glass are as follows:

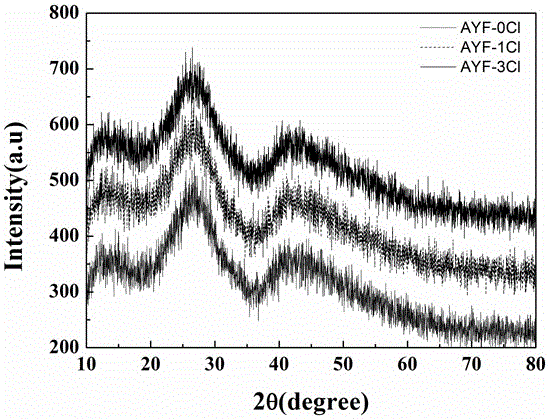

[0034] Take a little sample after annealing, grind it into a fine powder with an agate mortar, and carry out XRD analysis, as shown in figure 1 shown. The experimental results show that the glass has no obvious crystal phase and has good glass-forming performance. The matrix material is suitable fo...

Embodiment 2

[0036] According to table 1 in 1 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh each raw material and mix evenly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace with a melting temperature of 1000 ° C, and clarify it for 15 pour the molten glass into the preheated mold; quickly move the glass into the muffle furnace that has been heated to near the annealing temperature (450°C), keep it warm for 4 hours, and then lower it to room temperature at a rate of 10°C / hour. Remove the glass sample after complete cooling.

[0037] The test results for this glass are as follows:

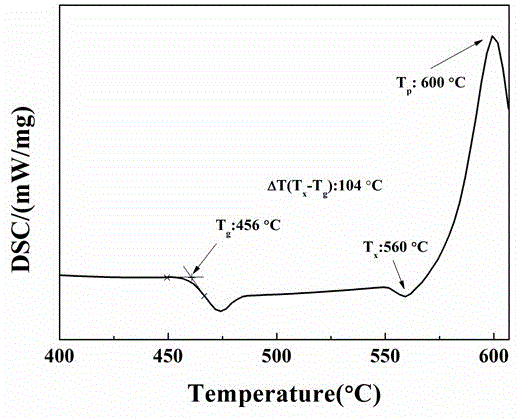

[0038] Take a little sample after annealing, grind it into a fine powder with an agate mortar, and carry out differential thermal analysis, as shown in figure 2 . The experimental results show that the glass sample has good devitrification resistance and can be used as 3 μm mid-infrared laser glass ...

Embodiment 3

[0040] According to table 1 in 2 # The mole percentage of the glass composition, calculate the corresponding weight of each composition, weigh each raw material and mix evenly; put the mixture into a corundum crucible and melt it in a silicon carbide rod electric furnace with a melting temperature of 1000 ° C, and clarify it for 15 pour the molten glass into the preheated mold; quickly move the glass into the muffle furnace that has been heated to near the annealing temperature (450°C), keep it warm for 4 hours, and then lower it to room temperature at a rate of 10°C / hour. Remove the glass sample after complete cooling.

[0041] The test results for this glass are as follows:

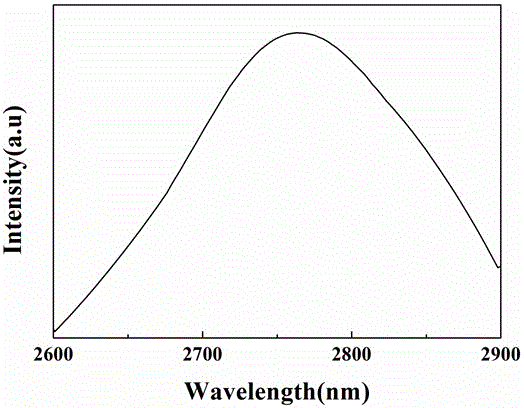

[0042] The annealed sample was processed into a 10×20×1.0 mm glass plate and polished, and its fluorescence spectrum was tested under the pumping of a laser diode with a wavelength of 980 nm, such as image 3 shown. Experiments show that the glass is transparent without devitrification. Obvious mid-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap