Air-conditioning air deflector, clustered molding composite material for manufacturing same and preparation method

A technology of mass molding and composite materials, which is applied in the field of air conditioners, can solve the problems that plague injection molding production, increase production costs, and deformation of parts, and achieve bright and uniform colors, easy manufacturing and production, and small size deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

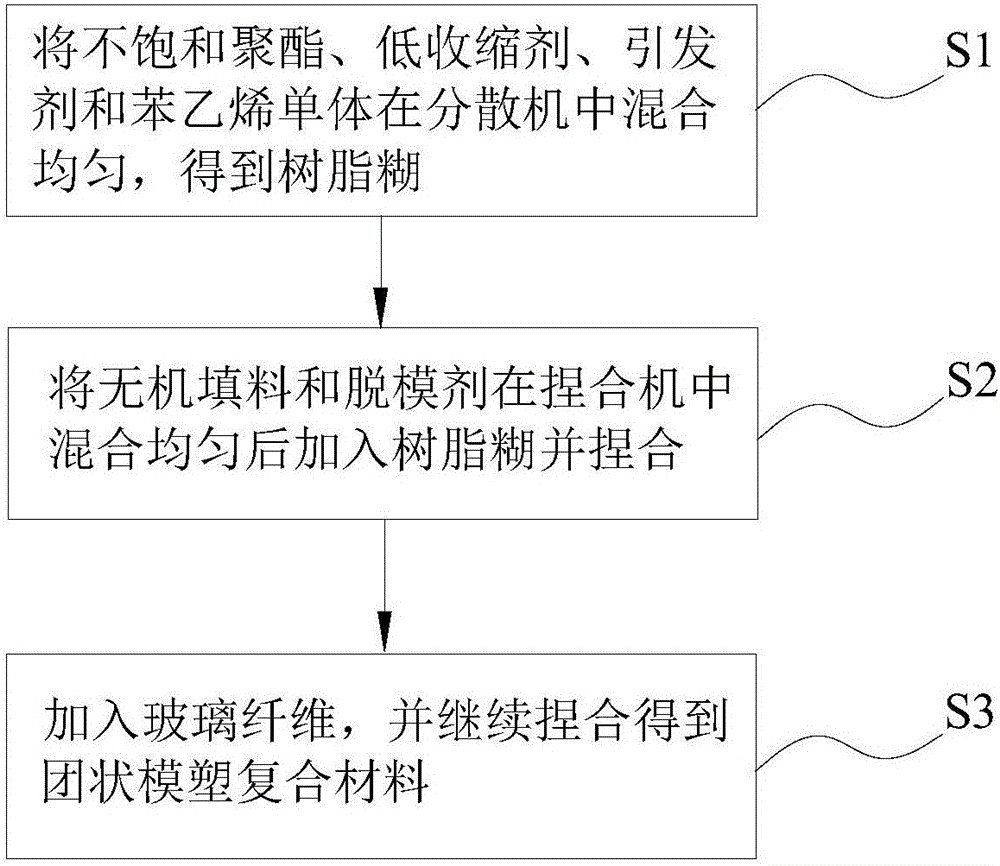

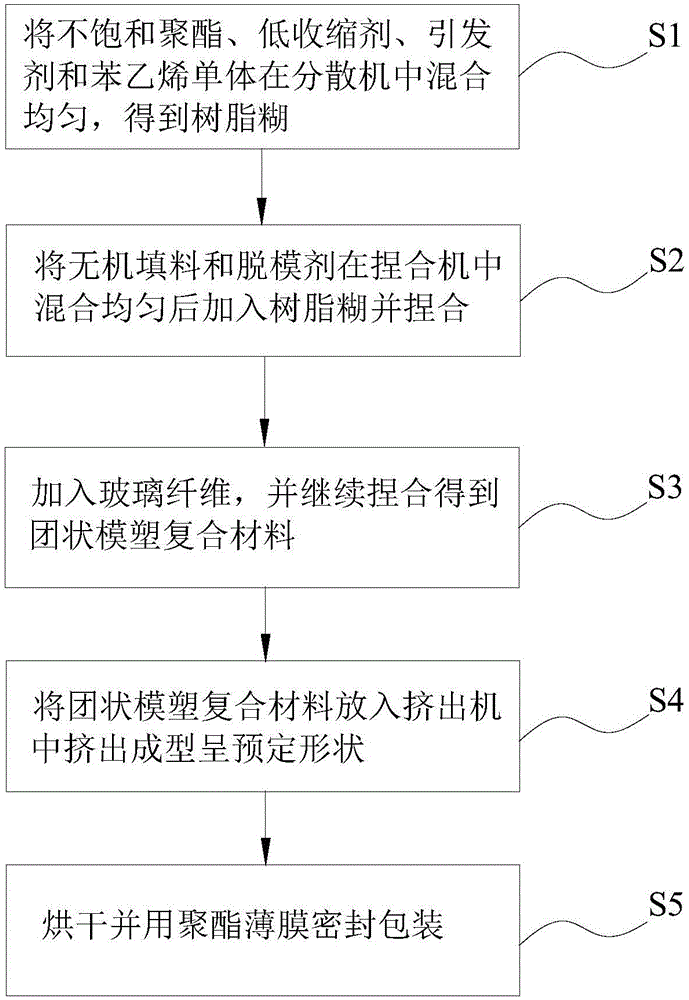

Method used

Image

Examples

Embodiment 1

[0061] 60 parts by weight of o-phthalic unsaturated polyester resin, 40 parts by weight of low shrinkage agent (wherein, 30 parts by weight of molecular weight is 50000 high degree of polymerization polystyrene, 10 parts by weight of molecular weight is 5000 low degree of polymerization polystyrene Ethylene), 0.3 part of TBPB, 0.7 part of TBPO, and 1 part of magnesium oxide were uniformly mixed in a high-speed mixer to obtain a resin paste. In addition, mix 90 parts of calcium carbonate with a median particle size of 12000 mesh, 10 parts of calcium carbonate with a median particle size of 1800 mesh, and 3.5 parts of zinc stearate in a kneader, add the previously prepared resin paste, and add 40wt % length is the chopped glass fiber of 6mm, kneading evenly obtains BMC composite material.

[0062] The air-conditioning wind deflector was molded on a compression molding machine with the BMC composite material thus obtained. The mold was heated by electricity, the surface temperatu...

Embodiment 2

[0064] Change the high degree of polymerization polystyrene that molecular weight is 50000 and the low degree of polymerization polystyrene that molecular weight is 5000 into 20 parts and 20 parts respectively, all the other are the same as embodiment 1. There are no pinholes and pitting on the surface of the wind deflector base, the surface is smooth, without ripples, the color is uniform and bright, the color difference is 0.80 after testing, the heat distortion temperature is 218°C, the bending strength is 77Mpa, and the impact strength is 14kJ / m 2 , better surface smoothness and gloss.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com