Modified white graphene composite antioxidation coating and preparation thereof

An anti-oxidation coating and white graphene technology, applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of limited anti-oxidation time and fast volatilization speed, and achieve great application value, strong anti-oxidation ability, and good adhesion The effect of force and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

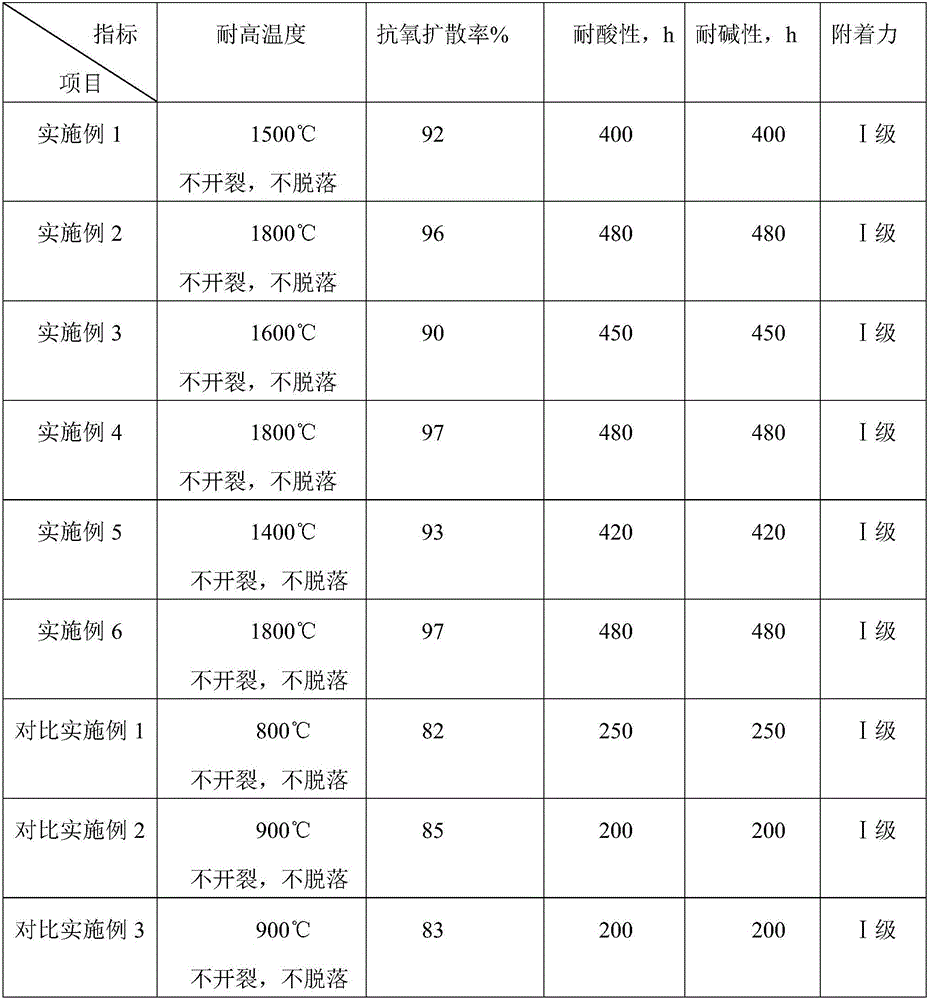

Examples

Embodiment 1

[0022] Step 1) surface modification of white graphene: select 5-10 layers of white graphene to soak in 0.3% oleylamine aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0023] Step 2) Preparation of modified white graphene composite anti-oxidation coating: Weigh 30 parts of acrylic resin, 10 parts of silica sol, 10 parts of KH-570 silane coupling agent and 50 parts of deionized water respectively by weight, and then add Mix and stir for 5 minutes at room temperature in a high-speed mixer. Then weigh 10 parts of spherical alumina, 20 parts of fumed silica, 10 parts of glass powder and 0.5 parts of modified white graphene and add them to a high-speed mixer in order to mix and stir. The temperature is controlled at 80°C for 15 minutes; after the end, the product is taken out Then grind for 120 minutes with a planetary grinder to obtain a composite anti-oxidation coating.

Embodiment 2

[0025] Step 1) surface modification of white graphene: select 5-10 layers of white graphene to soak in 0.3% oleylamine aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0026] Step 2) Preparation of modified white graphene composite anti-oxidation coating: Weigh 20 parts of acrylic resin, 10 parts of silica sol, 5 parts of KH-570 silane coupling agent and 40 parts of deionized water respectively by weight, and then add Mix and stir for 5 minutes at room temperature in a high-speed mixer. Then weigh 15 parts of spherical alumina, 10 parts of fumed silica, 7 parts of glass powder and 2.5 parts of modified white graphene and add them to a high-speed mixer in order to mix and stir. The temperature is controlled at 60°C and the time is 30 minutes; after the end, take out the product Then it was ground for 60 minutes by a planetary grinder to obtain a composite anti-oxidation coating.

Embodiment 3

[0028] Step 1) surface modification of white graphene: select 5-10 layers of white graphene to soak in 0.3% oleylamine aqueous solution for 24 hours, obtain modified white graphene after centrifugation and vacuum drying;

[0029] Step 2) Preparation of modified white graphene composite anti-oxidation coating: after weighing 30 parts of water-based polyurethane, 10 parts of silica sol, 8 parts of KH-570 silane coupling agent and 50 parts of deionized water in parts by weight, add in sequence Mix and stir for 5 minutes at room temperature in a high-speed mixer. Then weigh 10 parts of spherical alumina, 20 parts of fumed silica, 10 parts of glass powder and 0.5 parts of modified white graphene and add them to a high-speed mixer in order to mix and stir. The temperature is controlled at 80°C for 15 minutes; after the end, the product is taken out Then grind for 120 minutes with a planetary grinder to obtain a composite anti-oxidation coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com