High-hardness CrAlN coating layer containing multiphase AlCrN nanometer insertion layer and preparation method thereof

A high-hardness, intercalated layer technology, applied in the field of materials science, can solve the problems of hardness, oxidation resistance, deposition conditions and deposition efficiency, and achieve the effect of improving hardness and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation, characterization and measuring instruments used in the present invention:

[0032] JGP-450 Magnetron Sputtering System, Shenyang Scientific Instrument Development Center Co., Ltd., Chinese Academy of Sciences

[0033] D8 Advance X-ray diffractometer, Bruker, Germany

[0034] NANO Indenter G200 nanoindenter, Agilent Technologies, USA

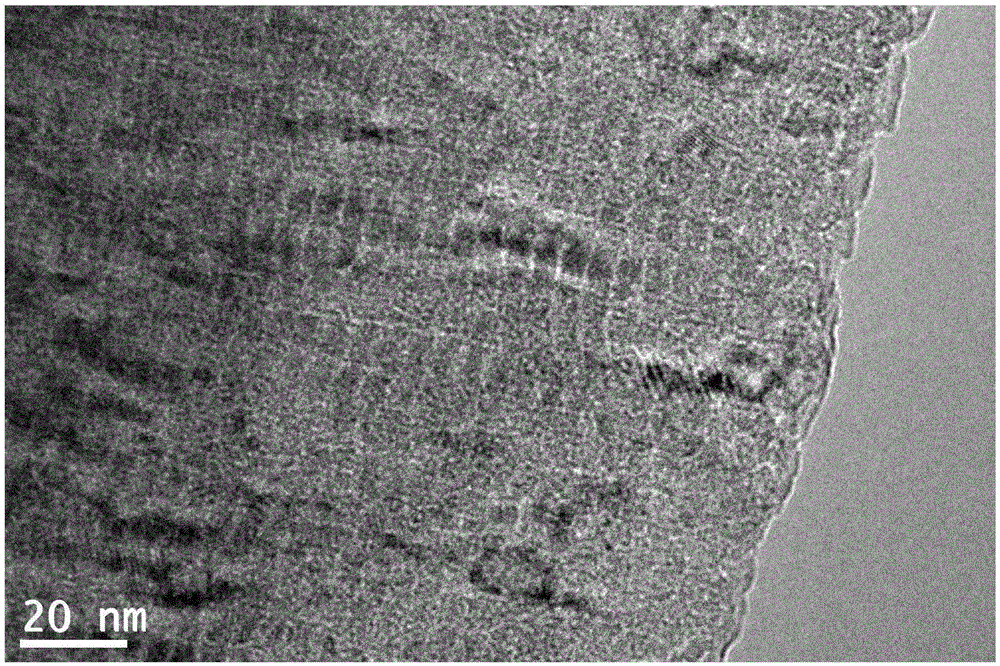

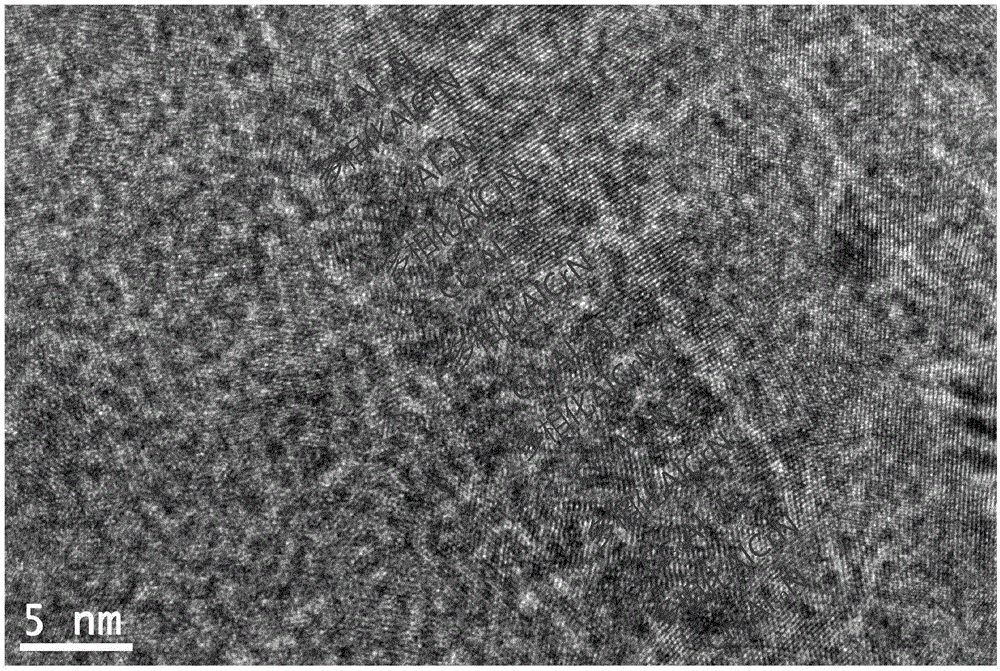

[0035] Tecnai G 2 Model 20 high-resolution transmission electron microscope, FEI, USA

[0036] Quanta FEG450 scanning electron microscope, American FEI company

Embodiment 1

[0038] Using Cr 50 al 50 (50 atom%:50 atom%) composite target and Al 80 Cr 20 (80 atom%:20 atom%) composite target with a diameter of 75mm;

[0039] Ar gas flow: 38sccm, N 2 Air flow: 5sccm; target base distance 3-7cm, total air pressure range 0.6Pa.

[0040] Cr 50 al 50 N-layer sputtering power DC 120W, time 12s; heterogeneous Al 80 Cr 20 N-layer sputtering power radio frequency 80W, time 2s;

[0041] After testing, the obtained Cr 50 al 50 N layer thickness is 4.0nm, heterogeneous Al 80 Cr 20 The thickness of the N layer is 0.3 nm, the total thickness is 1.8 μm, and the hardness is 35.4 GPa.

Embodiment 2

[0043] Using Cr 50 al 50 (50 atom%:50 atom%) composite target and Al 80 Cr 20(80 atom%:20 atom%) composite target with a diameter of 75mm;

[0044] Ar gas flow is 38sccm, N 2 The air flow rate is 5sccm; the target base distance is 3-7cm, and the total air pressure is 0.6Pa;

[0045] Cr 50 Al 50 N-layer sputtering power DC 120W, time 15s; heterogeneous Al 80 Cr 20 N layer sputtering power radio frequency 80W, time 3s.

[0046] After testing, the obtained Cr 50 Al 50 N layer thickness is 5.0nm, heterogeneous Al 80 Cr 20 The thickness of the N layer is 0.4 nm, the total thickness is 2.1 μm, and the hardness is 36.1 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com