Preparation method of magnetic graphene composite film

A magnetic graphene and composite film technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of reduced mechanical strength of materials, cracks and other problems, and achieves no polymer residue, good quality, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of a kind of preparation method of magnetic graphene composite film are as follows:

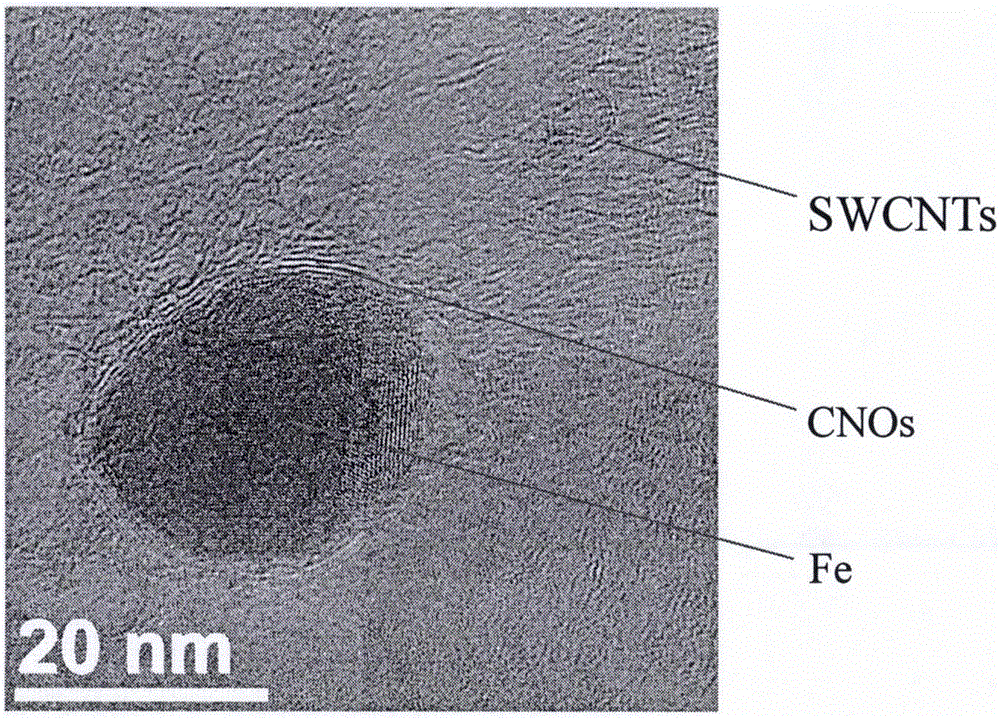

[0032] 1) Loaded carbon nanotubes

[0033]Put 9mg of F-127 into 10ml of deionized water, stir evenly to obtain a solution A with a concentration of F-127 of 0.088mol / L; add 7.2mg of SWCNTs to solution A, and disperse evenly in an ice bath by ultrasonic A mixed solution B with a concentration of SWCNTs of 0.06 mol / L was obtained, and the mixed solution B was spin-coated on a copper foil to obtain a copper foil C evenly loaded with SWCNTs. Among them, the ultrasonic power is 80W, the ultrasonic time is 30min, and the load of single-walled carbon nanotubes on the copper foil C is 7mg / cm 2 .

[0034] 2) In situ toughened graphene prepared by SWCNTs by chemical vapor deposition (CVD)

[0035] In the Ar atmosphere, place the copper foil C described in step 1) in the constant temperature zone of the CVD furnace, and then close the Ar. Vacuum down to -0.1MPa, and continu...

Embodiment 2

[0043] A kind of preparation method of magnetic graphene composite film, with embodiment 1, wherein: in the 1st) step, 20.9mgSDBS is put into 60ml deionized water, after stirring, obtain the solution that the amount concentration of SDBS substance is 0.001mol / L A; Add 72mg DWCNTs into solution A, and disperse evenly in an ice bath with 65W ultrasonic wave for 45min to obtain a mixed solution B with a concentration of DWCNTs of 0.1mol / L, and spin-coat the mixed solution B on copper foil to obtain Loading DWCNTs is 10mg / cm 2 The copper foil C.

[0044] In step 2), Ar is turned on, the copper foil C described in step 1) is placed in the constant temperature zone of the CVD furnace, and then Ar is turned off. Open H after vacuuming 2 , at 400sccm H 2 Heat reduction at 1050°C for 25min, then open CH 4 , at 400sccm H 2 and 10sccmCH 4 The chemical vapor phase growth was carried out for 10 min under the mixed gas atmosphere. Finally, the copper foil was quickly removed from the...

Embodiment 3

[0048] A kind of preparation method of magnetic graphene composite film, with embodiment 1, wherein: in the 1st) step, 28.8mg SDS is put into 10ml deionized water, after stirring, the amount concentration that obtains SDS substance is 0.01mol / L Solution A: Add 3.6 mg of SWCNTs to solution A, and disperse evenly in an ice bath with 30W ultrasonic for 60 minutes to obtain a mixed solution B with a concentration of SWCNTs of 0.03 mol / L, and spray the mixed solution B on the copper foil to obtain Loading SWCNTs is 0.4mg / cm 2 The copper foil C.

[0049] In step 2), Ar is turned on, the copper foil C described in step 1) is placed in the constant temperature zone of the CVD furnace, and then Ar is turned off. Open H after vacuuming 2 , at 350sccm H 2 Heat reduction at 850°C for 30min, then open CH 4 , at 350sccm H 2 and 15sccmCH 4 The chemical vapor phase growth was carried out for 55 minutes under the mixed gas atmosphere. Finally, the copper foil was quickly removed from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com