Protective composite material molded by means of spraying and method for preparing protective composite material

A composite material and bonding material technology, which is applied in the field of spray-molded protective composite materials and their preparation, can solve the problems of poor heat resistance of composite materials, discounted puncture resistance, easy liquid flow, etc., and achieves low production cost, High-efficiency molding and the effect of reducing the degree of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

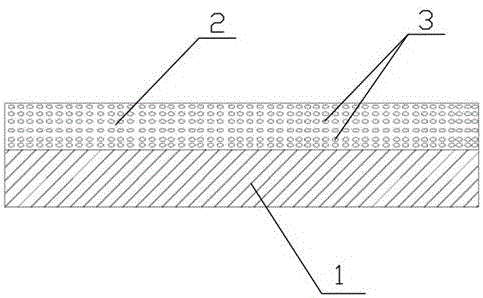

[0035] Aramid 1414 woven fabric with a surface density of 200g / m 2 , the thickness is 0.34mm, the warp and weft density is 110*110 / (root / 10cm), and the yarn linear density is 930D. The hot-melt adhesive film used is PES film with a thickness of 0.25mm; silicon carbide is used as the rigid particle material with a particle size of 80μm; the moving speed of the nozzle of the sandblasting machine is 18mm / s, and the nozzle sprays out rigid particles evenly. The spraying range is a circular area with a diameter of 50mm, and the spraying thickness is 0.4mm. The hot-pressing temperature of the continuous plate hot-pressing machine is 150° C., and the hot-pressing time is 15 s.

[0036] The preparation process of the rigid particle coating composite protective material of the present embodiment is as follows:

[0037] (1) Surface treatment of aramid 1414 woven fabric with organic solvents to remove slurry, wax and impurities on the surface of the fabric, and dry the fabric for later...

Embodiment 2

[0043] Made of glass fiber woven fabric with a surface density of 240g / m 2 , the thickness is 0.4mm, the warp and weft density is 85*85 / (root / 10cm), and the yarn linear density is 1600D. The hot-melt adhesive film used is PA film with a thickness of 0.3mm; zirconium corundum is used as the rigid particle material with a particle size of 100μm; the moving speed of the nozzle of the sandblasting machine is 16mm / s, and the nozzle ejects rigid particles evenly. The spraying range is a circular area with a diameter of 50mm, and the spraying thickness is 0.5mm. The hot-pressing temperature of the continuous plate hot-pressing machine is 165°C, and the hot-pressing time is 20s.

[0044] The preparation process of the rigid particle coating composite protective material of the present embodiment is as follows:

[0045] (1) Surface treatment of glass fiber woven fabrics with organic solvents to remove slurry, wax and impurities on the surface of the fabrics, and dry the fabrics for l...

Embodiment 3

[0051] Using basalt fiber woven fabric, surface density is 180g / m 2 , the thickness is 0.28mm, the warp and weft density is 130*130 / (root / 10cm) unknown, and the yarn linear density is 600D. The hot-melt adhesive film used is PUR film with a thickness of 0.3mm; alumina is selected as the rigid particle material with a particle size of 60μm; the moving speed of the nozzle of the sandblasting machine is 16mm / s, and the nozzle ejects rigid particles evenly. The spraying range is a circular area with a diameter of 50mm, and the spraying thickness is 0.2mm. The hot-pressing temperature of the continuous plate hot-pressing machine is 150° C., and the hot-pressing time is 25 s.

[0052] The preparation process of the rigid particle coating composite protective material of the present embodiment is as follows:

[0053] (1) Use an organic solvent to treat the surface of the basalt fiber woven fabric to remove the slurry, wax and impurities on the surface of the fabric, and dry the fab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com