Coating for lost foam casting

A lost foam casting and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of poor adhesion, coating and leveling, etc., achieve fast wetting speed, improve bonding strength, The effect of improving coating performance and leveling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

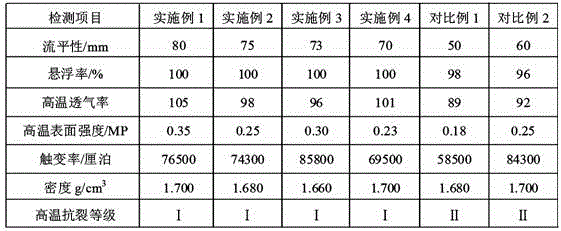

Examples

Embodiment 1

[0018] Bauxite 6.0kg, quartz powder 3.0kg, corn starch 120g, CMC 40g, yellow dextrin 60g, organic bentonite 140g, wood fiber 50g, polyurethane resin 150g, polyurethane modified phenolic resin 200g, fibrous wollastonite 340g.

Embodiment 2

[0020] Bauxite 5.9kg, quartz powder 2.8kg, potato starch 110g, CMC 50g, yellow dextrin 50g, organic bentonite 130g, wood fiber 60g, polyurethane resin 160g, polyurethane modified phenolic resin 180g, fibrous wollastonite 360g.

Embodiment 3

[0022] Bauxite 6.2kg, quartz powder 3.2kg, corn starch 130g, CMC 30g, yellow dextrin 70g, organic bentonite 160g, wood fiber 40g, polyurethane resin 140g, polyurethane modified phenolic resin 220g, fibrous wollastonite 320g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com