Pickling wastewater reuse method

A technology for pickling wastewater and purpose, applied in the field of pickling wastewater reuse, can solve problems such as resource waste, environmental pollution, salt loss, etc., and achieve the effect of reducing direct economic losses and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S10, pretreatment: collect 100Kg of pickling waste water with a salt content of 10%, pre-filter with a 150-mesh filter tank, then pass through a 250-mesh filter and boil for 10 minutes;

[0036] S20, flocculation: put the boiled pickled wastewater in a container, position it on a magnetic stirrer, add slaked lime to adjust the pH value to 7, add 90mg / L polyaluminum ferric chloride 2Kg, 60mg / L polyacrylic phthalein After mixing 2Kg of amine evenly, place it under the condition of 35°C and stir it rapidly for 3 minutes, then stir it at a medium speed for 30 seconds, and take the supernatant after standing for 30 minutes;

[0037] S30, microfiltration and ultrafiltration: pass the above supernatant through a ceramic microfiltration membrane with a membrane area of 0.24㎡ and a pore size of 100nm for 1 hour, and then use an ultrafiltration membrane with a molecular weight cut-off of 2000Da1 for 2 hours to obtain Filtrate; wherein, the microfiltration membrane feed velocity...

Embodiment 2

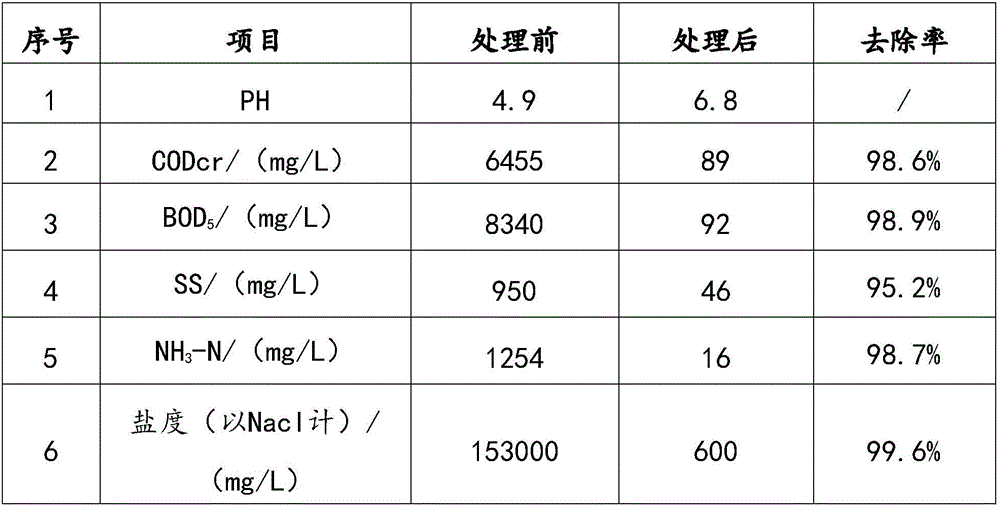

[0041] This embodiment is the detection of salinity, organic matter and nitrogen and phosphorus indicators in the treated pickling wastewater. By comparing COD, BOD, NH before and after treatment 3 -N, the removal situation of SS suspended solids, the salinity situation, verify the treatment effect of the recycling method of the present invention to pickling wastewater.

[0042] Detection and analysis method:

[0043] COD: GB11914-89, Determination of Chemical Oxygen Demand;

[0044] BOD: HJ505-2009, determination of water quality biochemical oxygen demand;

[0045] NH3-N: HJ 537-2009, determination of ammonia nitrogen in water quality;

[0046] SS suspended solids: GB11901, suspended solids in water quality.

[0047] Determination of salinity: according to the method specified in GB / T 12457 "Determination of Sodium Chloride in Food".

[0048] Indicators of pickling wastewater before and after treatment:

[0049]

[0050] Conclusion: As can be seen from the data in th...

Embodiment 3

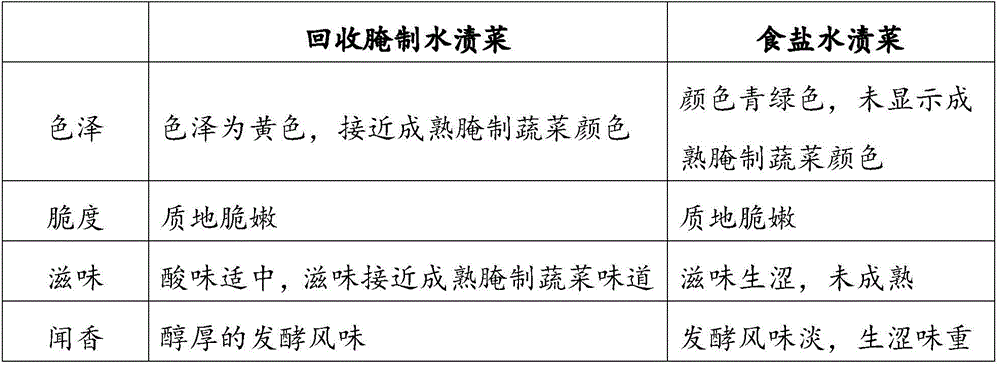

[0052] Use the pickled waste water treated by the embodiment of the present invention to salt fresh vegetables, and compare them with the same concentration of salt water to detect the changes in the heavy metal content and nitrite, and evaluate the sensory properties of the green vegetables to evaluate the treatment by this method. The safety degree of the pickling wastewater, so as to determine the feasibility of preparing pickled vegetables.

[0053] (1) Safety evaluation test:

[0054] Determination indicators and methods: Determination of nitrite: according to the method specified in GB / T 5009.33 "Determination of Nitrite and Nitrate in Food".

[0055] Related security tests:

[0056] Numbering

Test items

Test results

1

Lead (Pb)

<0.01, mg / L

2

Arsenic (As)

0.024, mg / L

3

not detected

4

<5000, mg / kg

5

Nitrosamines

not detected

[0057] Conclusion: the pickling wastew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com