Polymer hydrogel modified based on fe3+-dopamine and its preparation method

A polymer and dopamine technology, applied in the field of multifunctional polymer materials, can solve the problems of poor mechanical properties of Pluronis hydrogel, and achieve the effect of easy operation, pH responsive self-healing, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] PluF127-DOPA-Fe 3+ Preparation of hydrogel:

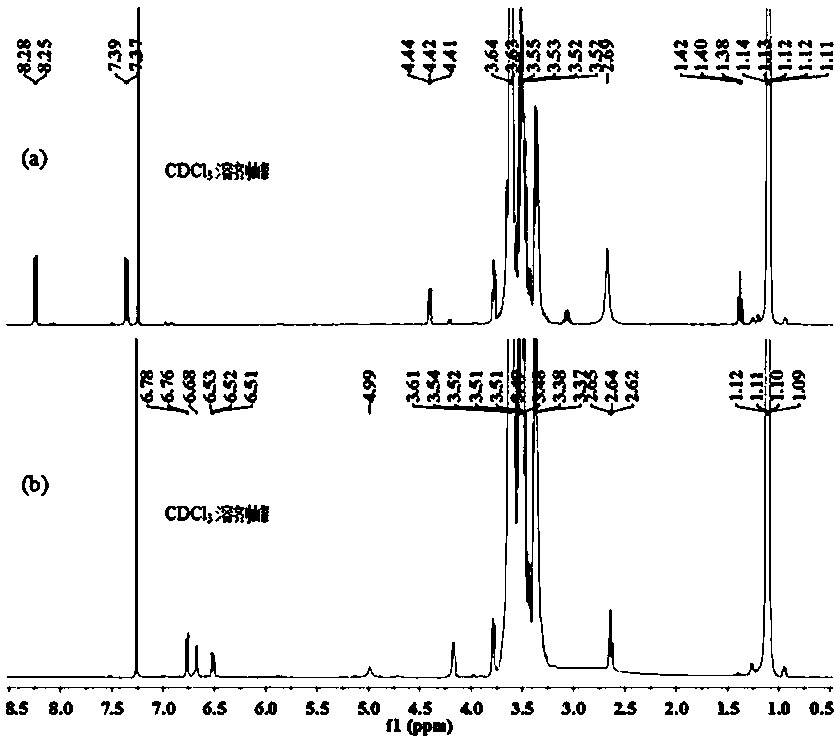

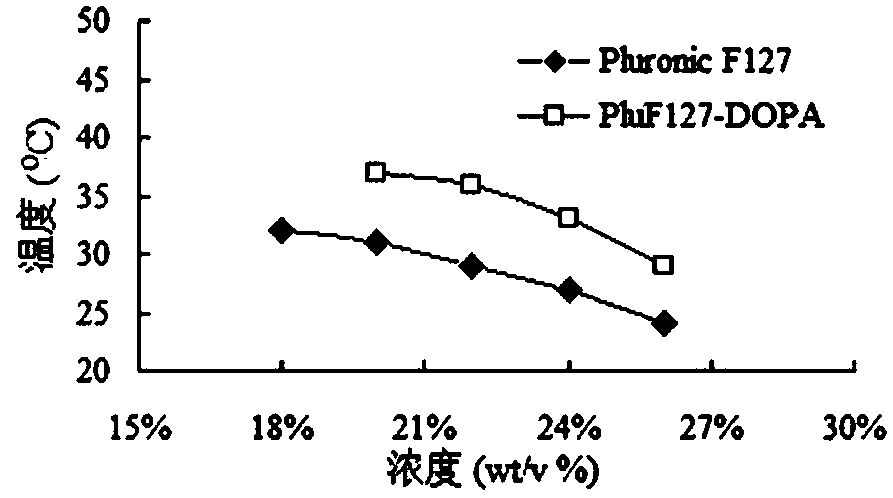

[0028] (1) Accurately weigh 0.9675g of p-nitrophenyl chlorate into a 250ml round bottom flask, add 10ml of anhydrous dichloromethane and stir to dissolve; dissolve 10g of hydroxyl-containing polymer Pluronic F127 in 60 mL of dichloromethane Add 245.5 μL of triethylamine to the methane solvent, and add the mixed solution dropwise into the methylene chloride solution dissolved with p-nitrophenyl chlorate under stirring and nitrogen protection; after the dropwise addition, mix the solution After stirring at 22°C for 48 hours, extract once with saturated NaCl solution, collect the organic phase, and dry the organic phase with anhydrous sodium sulfate for 30 min, filter it with suction and concentrate; drop the concentrated solution into anhydrous diethyl ether at 0°C , a white precipitate was obtained; filtered and dried in vacuo; the above titration and precipitation were repeated twice to obtain the purified p-nitrophenyl chl...

Embodiment 2

[0051] PluF68-DOPA-Fe 3+ Preparation of hydrogel:

[0052] (1) Accurately weigh 1.6900g of p-nitrophenyl chlorate into a 250ml round bottom flask, add 12ml of anhydrous dichloromethane and stir to dissolve; dissolve 12g of hydroxyl-containing polymer Pluronic F68 in 60 mL of dichloromethane Add 368 μL of triethylamine to the methane solvent, and add the mixed solution dropwise into the dichloromethane solution dissolved with p-nitrophenyl chlorate under stirring and nitrogen protection; after the dropwise addition, the mixed solution is After stirring at 30°C for 48 hours, extract once with saturated NaCl solution, collect the organic phase, and dry the organic phase with anhydrous sodium sulfate for 30 min, then filter with suction and concentrate; drop the concentrated solution into anhydrous diethyl ether at 4°C, Obtain a white precipitate; filter and dry in vacuo; repeat the above titration and precipitation twice to obtain the purified p-nitrophenyl chlorate-activated poly...

Embodiment 3

[0058] PEG10000-DOPA-Fe 3+ Preparation of hydrogel:

[0059] (1) Accurately weigh 2.4188g of p-nitrophenyl chlorate into a 250ml round bottom flask, add 20ml of anhydrous dichloromethane and stir to dissolve; dissolve 20g of hydroxyl-containing polymer polyethylene glycol 10000 (PEG10000) In 100mL of dichloromethane solvent, add 613.6μL of triethylamine, under stirring and nitrogen protection, add the mixed solution dropwise to the dichloromethane solution in which p-nitrophenyl chlorate is dissolved; dropwise After completion, the mixed solution was stirred at 26°C for 48 hours, extracted once with a saturated NaCl solution, collected the organic phase, and dried the organic phase with anhydrous sodium sulfate for 30 minutes, then suction filtered and concentrated; the concentrated solution was dropped to 2°C In anhydrous ether, a white precipitate was obtained; filtered and vacuum-dried; the above titration and precipitation were repeated twice to obtain the purified p-nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com