Combined-cycle indirect air cooling system

An air-cooling system and combined cycle technology, which is applied in steam engine installations, steam applications, machines/engines, etc., can solve problems such as high coal consumption rate, poor performance of steam turbine final stage variable working conditions, and poor heat transfer effect of air-cooled islands, etc., to achieve broad Application prospects, huge economic benefits, and the effect of improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

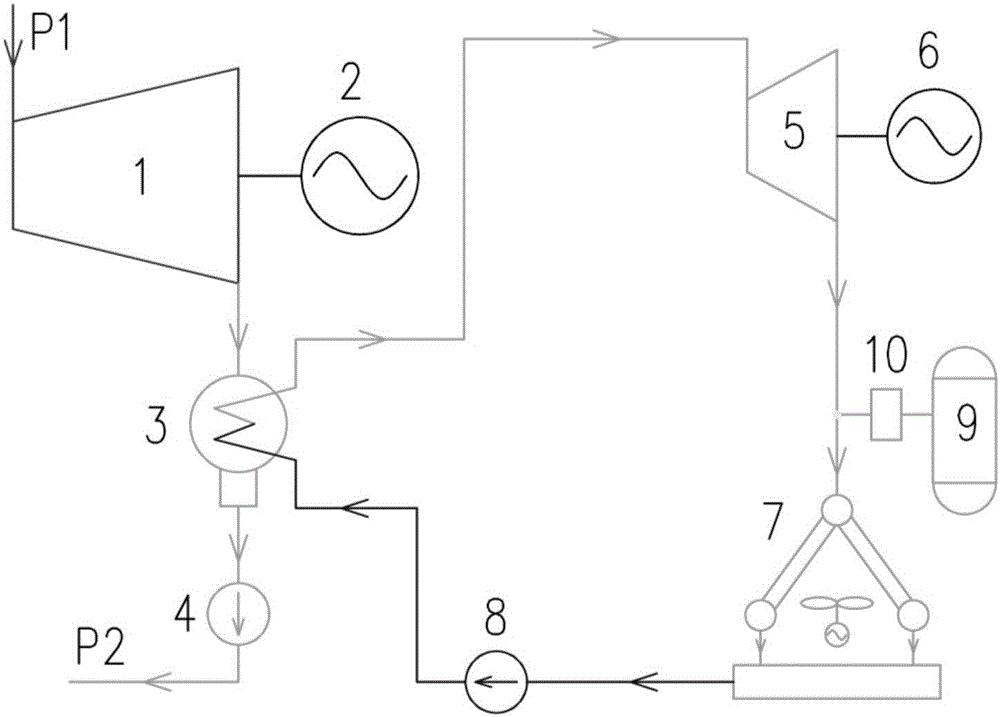

[0035] A combined cycle indirect air cooling system for large coal-fired power plants, such as attached figure 2 shown. The system uses the water vapor Rankine cycle operating at high back pressure as the upper cycle, and the air-cooled Rankine cycle with low freezing point working fluid as the lower cycle to form a high-efficiency combined cycle system, which is equivalent to reducing the temperature of the cold source of the coal-fired unit to close to ambient temperature.

[0036] The circulation system mainly includes main steam turbine 1, main generator 2, condenser 3, condensate pump 4, working medium turbine 5, auxiliary generator 6, air cooling island 7, working medium pump 8, working medium tank 9 and working medium Quality pressure regulating device 10.

[0037] The working process of the circulation system is: the liquid working fluid from the air-cooled island enters the condenser 3 after being pressurized by the working medium pump 8, and is used to condense th...

Embodiment 2

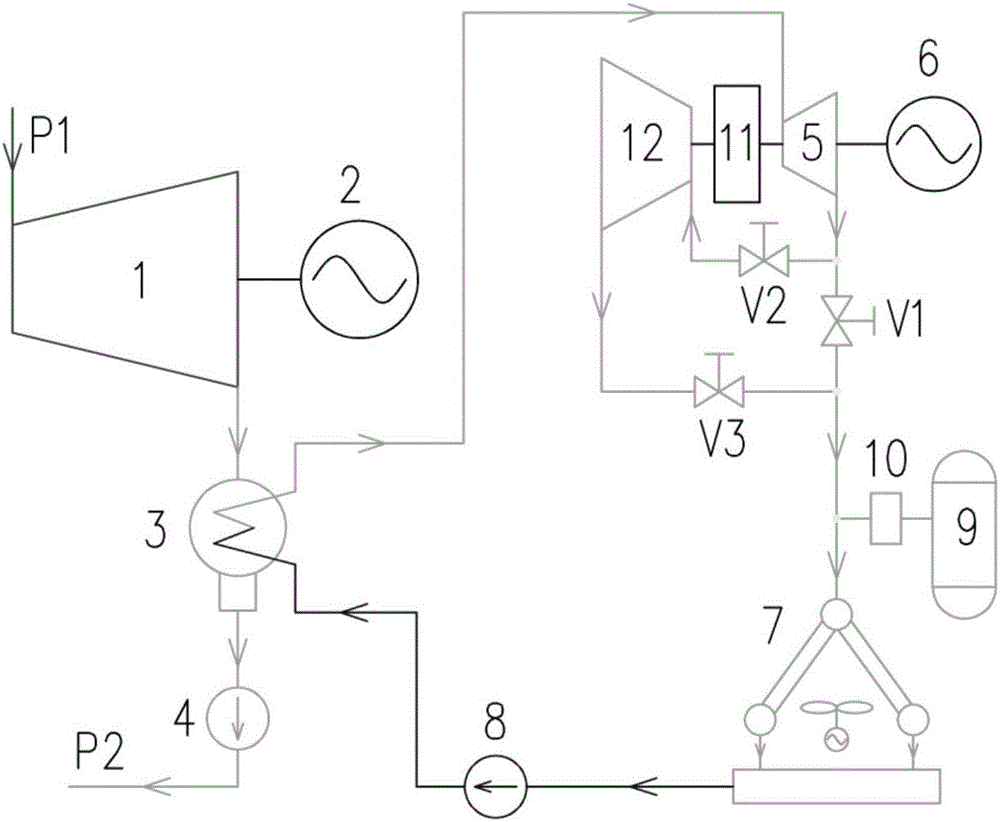

[0040] A combined cycle indirect air cooling system for large coal-fired power plants, such as attached image 3 shown. The system uses the water vapor Rankine cycle operating at high back pressure as the upper cycle, and the air-cooled Rankine cycle with low freezing point working fluid as the lower cycle to form a high-efficiency combined cycle system, which is equivalent to reducing the temperature of the cold source of the coal-fired unit to close to ambient temperature.

[0041] The circulation system mainly includes main steam turbine 1, main generator 2, condenser 3, condensate pump 4, working medium turbine 5, auxiliary generator 6, air cooling island 7, working medium pump 8, working medium tank 9, working medium Mass pressure regulating device 10, clutch 11, low-pressure working fluid turbine 12, and control valves V1, V2, V3.

[0042] The working process of the circulation system is: the liquid working medium from the air-cooling island 7 is pressurized by the wor...

Embodiment 3

[0046] A combined cycle indirect air cooling system for large coal-fired power plants, such as attached Figure 4 shown. The system uses the water vapor Rankine cycle operating at high back pressure as the upper cycle, and the air-cooled Rankine cycle with low freezing point working fluid as the lower cycle to form a high-efficiency combined cycle system, which is equivalent to reducing the temperature of the cold source of the coal-fired unit to close to ambient temperature.

[0047] The circulation system mainly includes main steam turbine 1, main generator 2, condenser 3, condensate pump 4, special working medium turbine 5, auxiliary generator 6, air cooling island 7, working medium pump 8, working medium tank 9, Working medium pressure regulating device 10, circulating fan 13, and control valves V1, V4, V5, V6, V7, V8, V9.

[0048] The working process of the circulation system is: when the ambient temperature is lower than the set temperature B, the control valves V1, V4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com