Method for preparing lithium-sulfur battery cathode Li2S/NCs composite material by activating and reducing lithium sulfate by using biomass wastes

A technology of biomass waste and composite materials, which is applied in the field of lithium-sulfur battery cathode material preparation, can solve problems such as environmental pollution and complicated preparation process, and achieve the effects of environmental friendliness, simple operation process and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh bagasse powder (3.0g), Li 2 SO 4(1.0g) and urea (2.0g) were added to a round-bottomed flask filled with 50mL of water, mixed evenly, stirred magnetically in an oil bath at 80°C for 10 hours, and finally the obtained mixture was rotary evaporated at 55°C Remove excess water and move into magnetic boat;

[0030] (2) Send the magnetic boat into the tube furnace, feed nitrogen protective gas, heat the mixture to 800°C at a heating rate of 5°C / min and keep it warm at this temperature for 2 hours, then naturally cool to 100°C;

[0031] (3) The calcined material is ground in an anhydrous environment and stored under dry conditions.

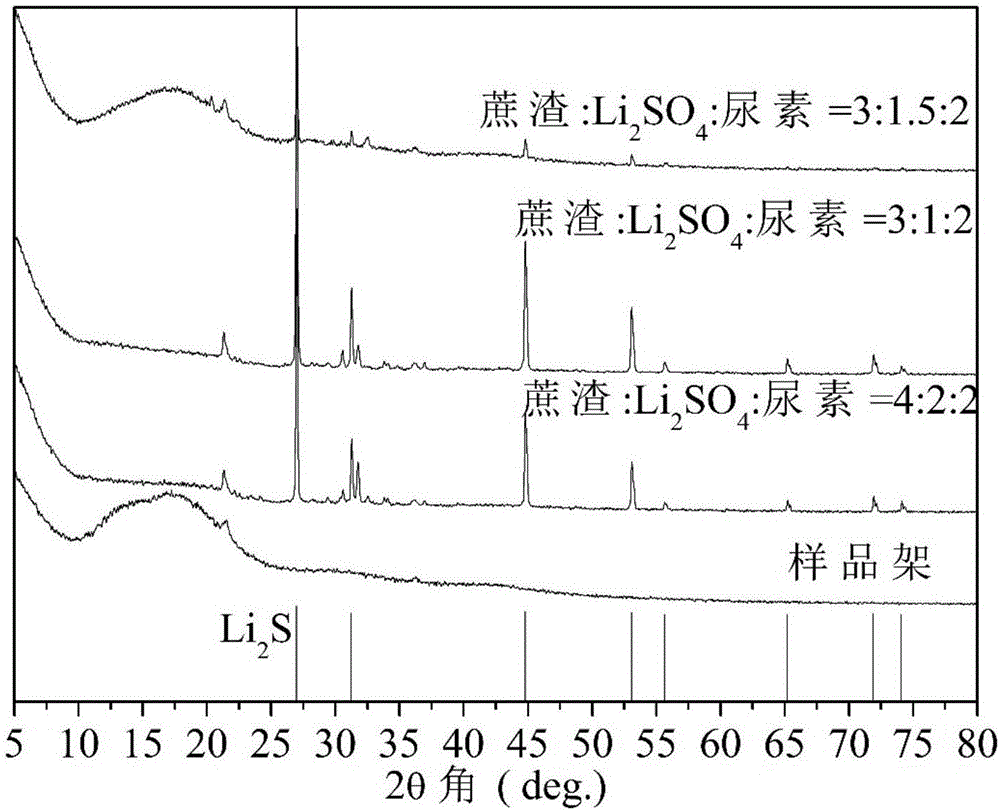

[0032] Li got 2 The x-ray powder diffraction pattern (XRD) of the S / NCs composite is as figure 1 shown. Depend on figure 1 It can be seen that the reaction process of Example 1 has successfully generated Li 2 S, but the non-background miscellaneous peaks near 20 degrees show that there are still impurities in the product.

Embodiment 2

[0034] (1) Weigh bagasse powder (3.0g), Li 2 SO 4 (1.5g) and urea (2.0g) were added to a round-bottomed flask filled with 50mL of water, mixed evenly, stirred magnetically in an oil bath at 80°C for 10 hours, and finally the resulting mixture was rotary evaporated at 55°C Remove excess water and move into magnetic boat;

[0035] (2) Send the magnetic boat into the tube furnace, feed nitrogen protective gas, heat the mixture to 800°C at a heating rate of 5°C / min and keep it warm at this temperature for 2 hours, then naturally cool to 100°C;

[0036] (3) The calcined material is ground in an anhydrous environment and stored under dry conditions.

[0037] Li got 2 The x-ray powder diffraction pattern (XRD) of the S / NCs composite is as figure 1 shown. Depend on figure 1 It can be seen that the reaction process of Example 2 has successfully generated Li 2 S, and there is no obvious non-background impurity peak.

Embodiment 3

[0039] (1) Weigh bagasse powder (4.0g), Li 2 SO 4 (2.0g) and urea (2.0g) were added to a round-bottomed flask filled with 50mL of water, mixed uniformly, stirred magnetically in an oil bath at 80°C for 10 hours, and finally the resulting mixture was rotary evaporated at 55°C Remove excess water and move into magnetic boat;

[0040] (2) Send the magnetic boat into the tube furnace, feed nitrogen protective gas, heat the mixture to 800°C at a heating rate of 5°C / min and keep it warm for 2 hours at this temperature, and then naturally cool to 150°C;

[0041] (3) The calcined material is ground in an anhydrous environment and stored under dry conditions.

[0042] Li got 2 The x-ray powder diffraction pattern (XRD) of the S / NCs composite is as figure 1 shown. Depend on figure 1 It can be known that the reaction process of Example 3 has successfully generated Li 2 S, and there is no obvious non-background impurity peak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com