A kind of molybdenum oxide electrochromic nano film and preparation method thereof

An electrochromic and nano-thin film technology, applied in the direction of coating, etc., can solve the problems of weak support, large film forming roughness, and difficulty in achieving complete uniformity of dispersion, and achieve uniform appearance, good repeatability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

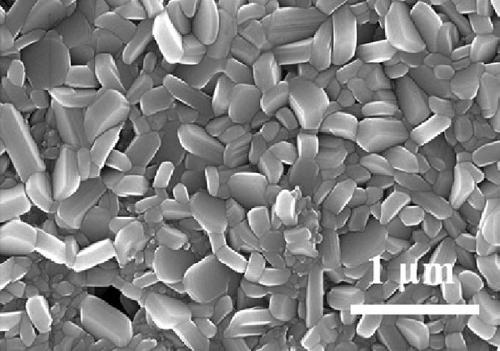

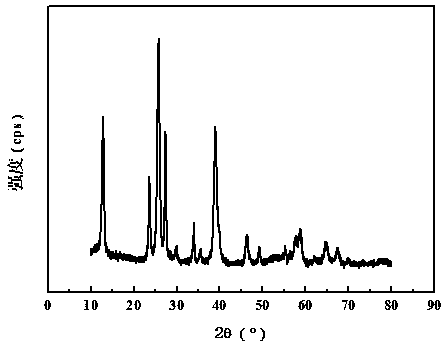

[0033] 1) 1.2 g of molybdenum powder, 8 ml of 30% hydrogen peroxide and 32 ml of deionized water were mixed and dissolved, stirred magnetically in an ice-water bath, and aged for 6 h to form a uniform transparent yellow solution.

[0034] 2) Add 1 g NaNO to the solution obtained in 1) 3 and 2 ml polyethylene glycol PEG, then transfer the precursor solution to a polytetrafluoroethylene reactor core with a capacity of 50 mL, and then put a piece of FTO conductive glass with a size of 2.5*5 cm in the reactor core, The conductive side was facing down, reacted at 180 °C for 12 h, and cooled naturally to room temperature after the reaction.

[0035] 3) Take out the FTO conductive glass in 2) the reaction kettle, soak it in anhydrous ethanol solution for 20 minutes, dry it at room temperature for 8 hours, and put the obtained film in a muffle furnace at 450 °C for 1 hour. The film is dark blue The color becomes white, and the molybdenum oxide film with the properties to be tested is...

Embodiment 2

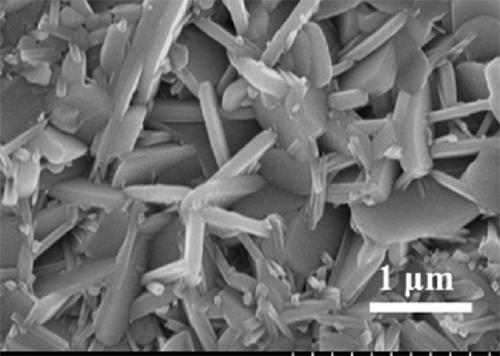

[0038] 1) 1.2 g of molybdenum powder, 8 ml of 30% hydrogen peroxide and 32 ml of deionized water were mixed and dissolved, stirred magnetically in an ice-water bath, and aged for 5 h to form a uniform transparent yellow solution.

[0039] 2) Add 1 g sodium citrate and 1 ml polyethylene glycol PEG to the solution obtained in 1), and then transfer the precursor solution to a polytetrafluoroethylene reactor core with a capacity of 50 mL, and then transfer it to the reactor core Put a piece of FTO conductive glass with a size of 2.5*5 cm, with the conductive side facing down, react at 180 °C for 6 h, and cool to room temperature naturally after the reaction.

[0040]3) Take out the FTO conductive glass in 2) the reaction kettle, soak it in anhydrous ethanol solution for 15 minutes, dry it at room temperature for 6 hours, and put the obtained film in a muffle furnace at 450 °C for 1 hour. The film is dark blue The color becomes white, and the molybdenum oxide thin film with the ele...

Embodiment 3

[0044] 1) Mix and dissolve 1.2 g of molybdenum powder, 8 ml of 30% hydrogen peroxide and 32 ml of deionized water, magnetically stir in an ice-water bath, and age for 10 hours to form a uniform transparent yellow solution.

[0045] 2) Add 1 g NaNO to the solution obtained in 1) 3 and 2 ml of n-butanol, then transfer the precursor solution to a polytetrafluoroethylene reactor core with a capacity of 50 mL, and then put a piece of FTO conductive glass with a size of 2.5*5 cm in the reactor core, in which the conductive Face down, react at 120 °C for 12 h, and cool to room temperature naturally after the reaction.

[0046] 3) Take out the FTO conductive glass in 2) the reaction kettle, soak it in anhydrous ethanol solution for 18 minutes, dry it at room temperature for 5 hours, and put the obtained film in a muffle furnace at 400°C for 1 hour. The film is dark blue The color becomes white, and the molybdenum oxide film with the properties to be tested is obtained.

[0047] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com