Lead-carbon battery negative pole preparation method based on ZIF-8 zeoliteimidazate framework porous carbon nanomaterial

A zeolite imidazolate and nanomaterial technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., to achieve the effects of high specific surface area, inhibition of irreversible sulfation, and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a lead-carbon battery negative electrode based on a ZIF-8 zeolite imidazolate framework porous carbon nanomaterial, comprising the following steps:

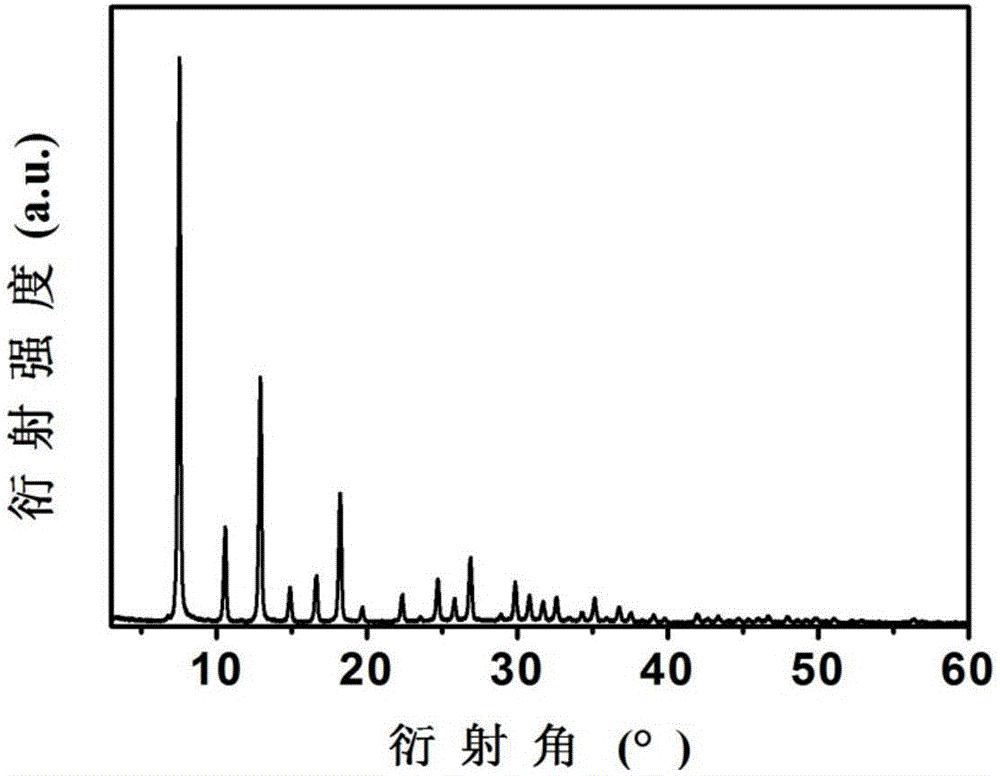

[0032] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 7000 rad / min and washed 3 times to obtain a white paste. The prepared white paste was dried for 8 hours in a blast dryer at 60°C, and dried in a vacuum oven at 105°C for 5 hours to obtain a ZIF-8 zeolite imidazolate skeleton, whose XRD pattern is as follows: figure 1 shown;

[0033] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep...

Embodiment 2

[0039] A preparation method of a lead-carbon battery negative electrode based on a ZIF-8 zeolite imidazolate framework porous carbon nanomaterial, comprising the following steps:

[0040] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 6000 rad / min and washed 3 times to obtain a white paste. The prepared white paste was dried in a blast dryer at 60°C for 10 hours, and dried in a vacuum oven at 100°C for 5 hours to obtain a ZIF-8 zeolite imidazolate skeleton;

[0041] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep it in a tube furnace with a nitrogen atmosphere ...

Embodiment 3

[0047] A preparation method of a lead-carbon battery negative electrode based on a ZIF-8 zeolite imidazolate framework porous carbon nanomaterial, comprising the following steps:

[0048] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 7000 rad / min and washed twice to obtain a white paste. The prepared white paste was dried in a blast dryer at 60°C for 9 hours, and dried in a vacuum oven at 105°C for 5 hours to obtain a ZIF-8 zeolite imidazolate skeleton;

[0049] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep it in a tube furnace with a nitrogen atmosphere at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com