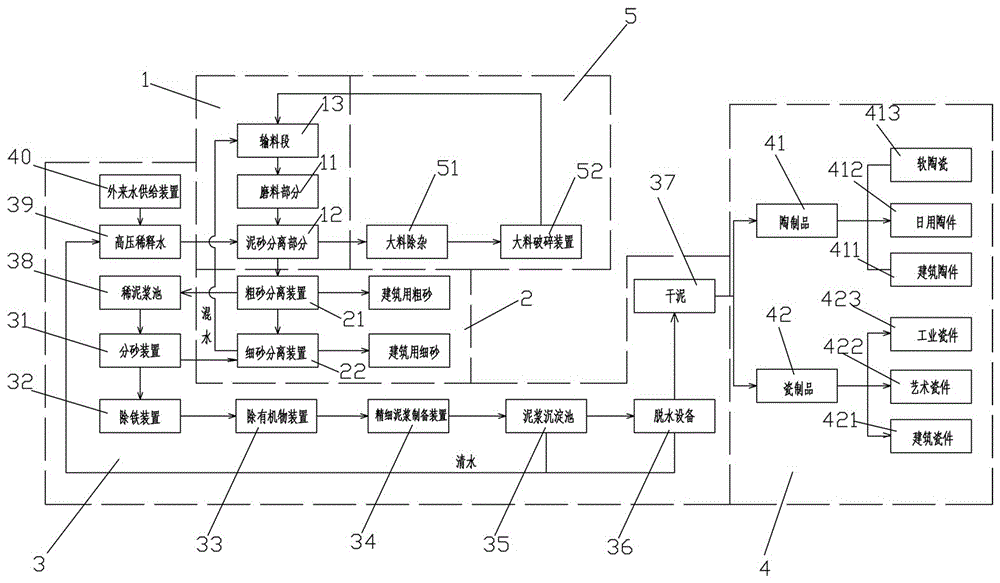

System for industrially treating silt residue soil

A technology of silt, silt and sand, which is applied in the field of slag treatment systems, and can solve problems such as man-made losses, man-made landslides, casualties and property losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: 80% of soil, 20% of soil modifier, mixed evenly, and further mixed in an internal mixer at a temperature of 130-150 degrees Celsius to form;

Embodiment 2

[0047] Example 2: 85% of soil, 15% of soil modifier, mixed evenly, and then further mixed in an internal mixer at a temperature of 130-150 degrees Celsius to form;

[0048] Implementation: 3: The soil is 90%, and the soil modifier is 10%, mixed evenly, and then further mixed in an internal mixer under the condition of 130-150 degrees Celsius, and it can be formed;

[0049] As for the soil modifier, it can be mixed with 5-8 parts of cellulose, 1-3 parts of urea and 6-10 parts of ethylene-vinyl acetate copolymer;

[0050] For example, it can be made by mixing 5 parts of cellulose, 1 part of urea and 6 parts of ethylene-vinyl acetate copolymer; it can also be mixed with 7 parts of cellulose, 2 parts of urea and 8 parts of ethylene-vinyl acetate copolymer It can also be mixed with 8 parts of cellulose, 3 parts of urea and 10 parts of ethylene-vinyl acetate copolymer.

[0051] The cellulose in the present invention can be hydroxyethyl cellulose, hydroxypropyl methyl cellulose or h...

Embodiment 3

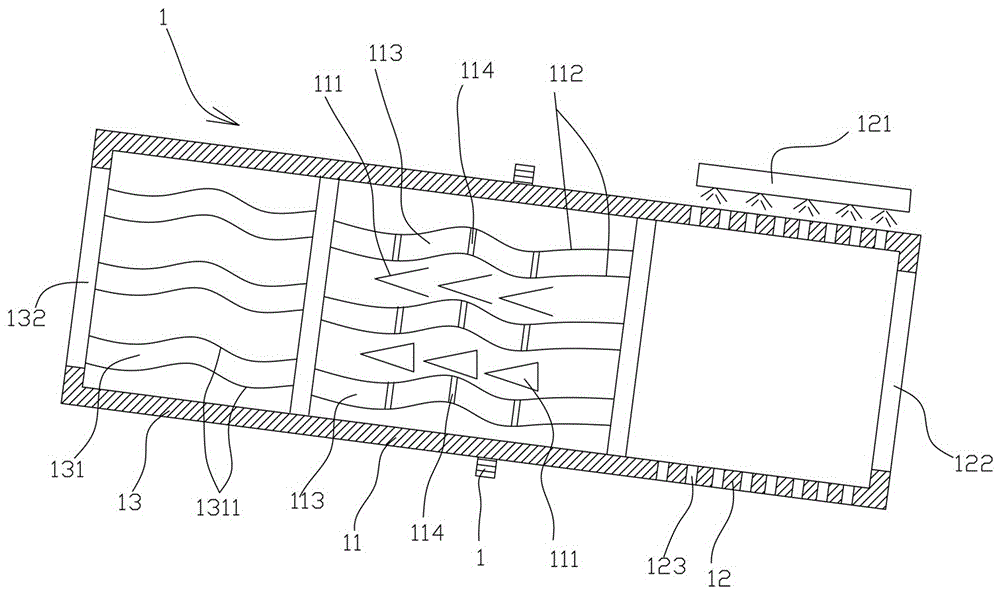

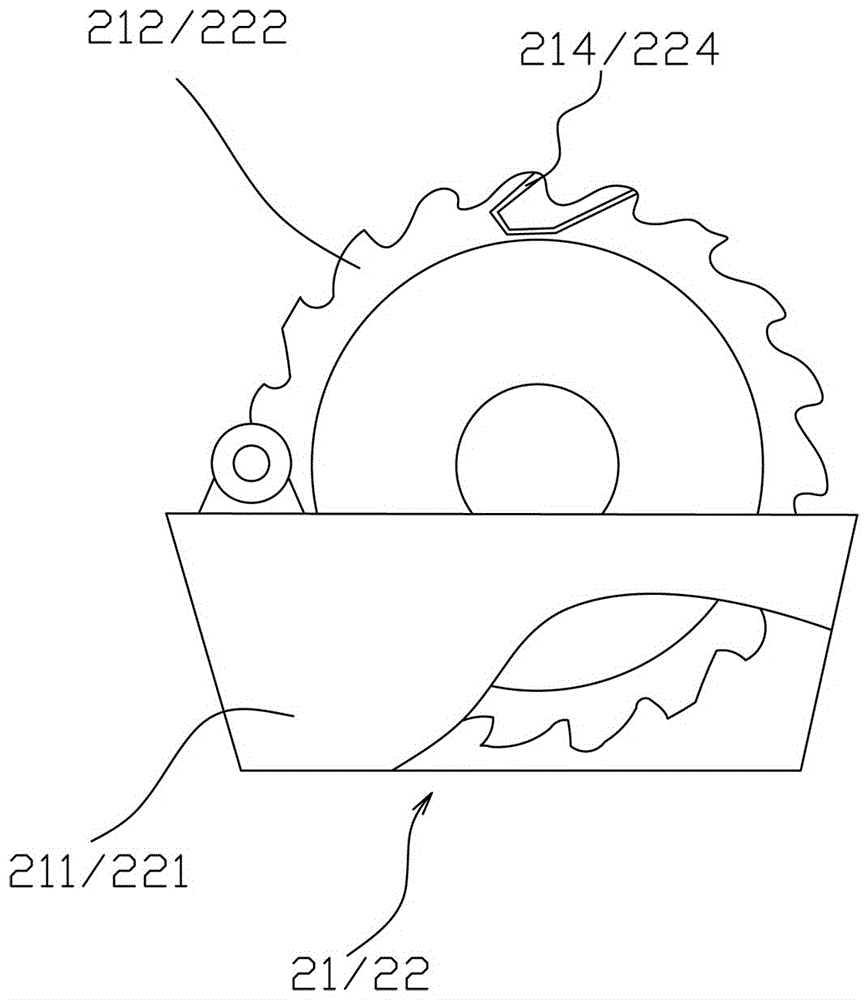

[0083] The abrasive member 111 can be made of the following high carbon iron alloy, which is composed of 16% by weight of titanium, 6% of carbon, 3% of silicon, 3% of lead, 8% of tungsten carbide, 0.3% of copper, 5% of boron, and 5% of chromium. , the remainder is iron.

[0084] The difference between the above alloys is that copper is generally considered a harmful element for iron alloys and cannot be used, but the present invention greatly improves the iron-titanium alloy by adding copper element and tungsten carbide into the iron-titanium alloy. Wear resistance.

[0085] Abrasive parts of the present invention and the comparison test method and results of the wear resistance of iron and titanium alloys purchased on the market:

[0086] Test method, using device, ML-10 abrasive wear testing machine, 200# corundum sandpaper, balance of 1 / 10,000 precision. The sample speed was 180 rpm, the normal load force was 750 N, and the time was 4 hours.

[0087] test results:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com