Penicillium chrysogenum and ferrihydrite aggregate and production method and application thereof

A technology for producing Penicillium chrysogenum and ferrihydrite, which is applied to chemical instruments and methods, water pollutants, biological water/sewage treatment, etc., can solve the problems of cumbersome operation steps and high cost, and achieve improved treatment efficiency, simple operation, The effect of high biosafety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of penicillium chrysogenum fungus (Penicillium Chrysogenum F) of the present invention is obtained by screening by the following method:

[0036] (1) Put 5g of slag from the Zhuzhou smelter into the sterilized 100mL conical flask of enrichment culture solution from the collected soil sample, and cultivate it on a constant temperature culture shaker for 24 hours to achieve the effect of enrichment.

[0037] (2) Take 1 mL of the enriched culture solution and dilute it to different times with sterile water. Select a suitable concentration of culture solution and inoculate it on the fungal isolation medium plate by pouring plate, streaking and dilution coating methods, and place it in a 35-37°C incubator until a single colony grows. Several good strains were repeatedly isolated and purified by streaking on plates until purified strains were obtained. The obtained Penicillium chrysogenum fungus was used to prepare a bacterial suspension: inoculate the spores of Penic...

Embodiment 2

[0043] A preparation method of Penicillium chrysogenum-ferrihydrite aggregate, comprising the following steps:

[0044] (1) Preparation of ferrihydrite: Take 45g ferric nitrate and dissolve it in 500mL deionized water, then add 1mol L -1 Adjust the pH to 7-8 with KOH, and adjust the pH to neutral with KOH after stirring vigorously. After standing still and removing the supernatant, the precipitate was washed with normal saline after the pH was stabilized, centrifuged at 3000rpm for 5min, and the precipitate was taken out in a beaker and air-dried at room temperature to obtain ferrihydrite powder.

[0045] (2) Preparation of Penicillium chrysogenum suspension: inoculate the spores of Penicillium chrysogenum in PDA liquid medium, shake and cultivate at 35-37°C for 24 hours to obtain a fungal suspension containing a large number of hyphae, and the concentration of the suspension is 0.432g / mL (weighing method).

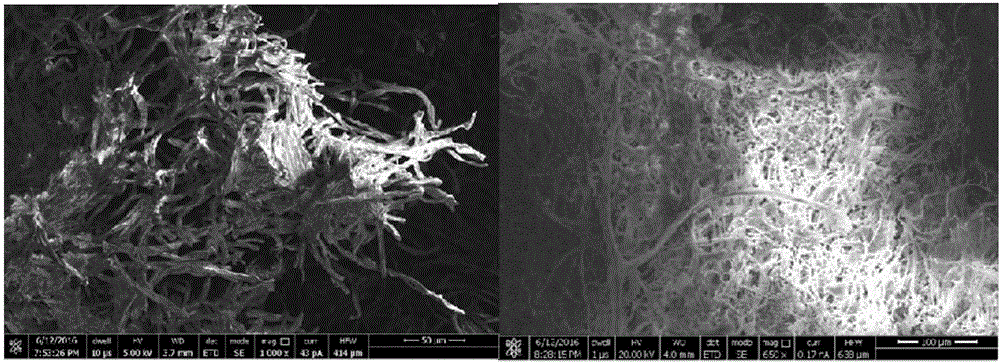

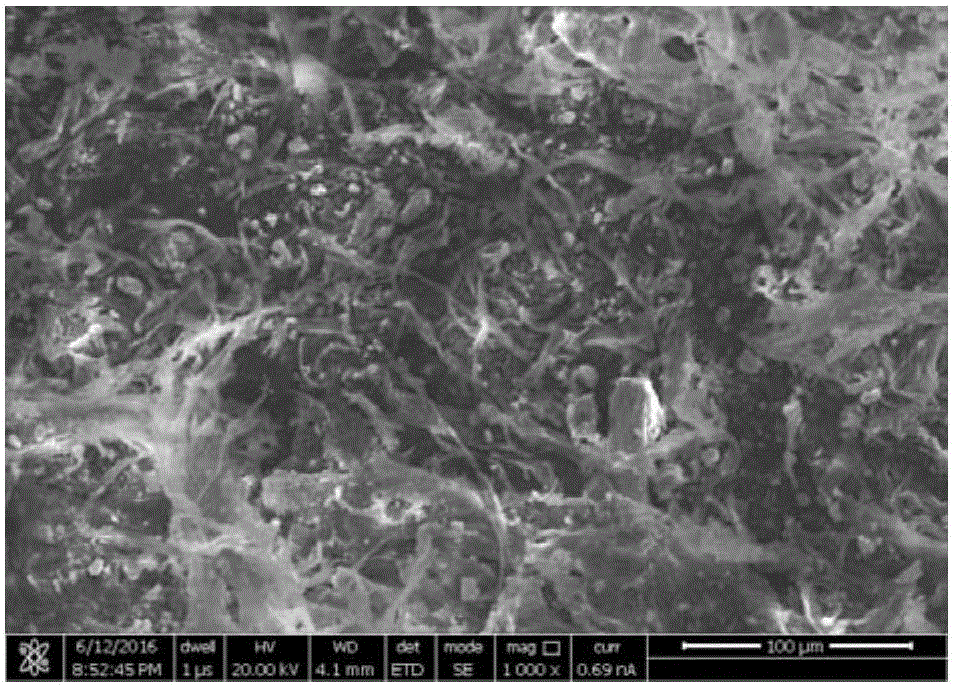

[0046] (3) Add 0.3 g of ferrihydrite into 15 ml of Penicillium chr...

Embodiment 3

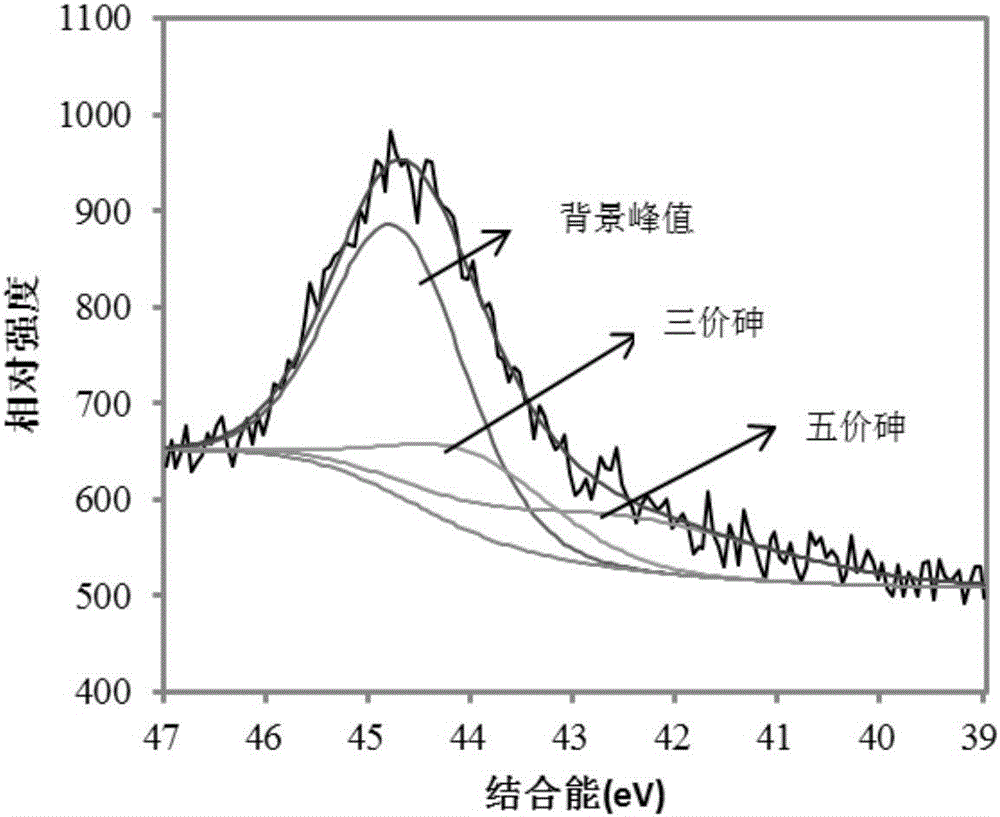

[0051] Investigate the effects of different ferrihydrite content and different bacterial suspension content on the treatment of arsenic-containing wastewater:

[0052] Group A: Mix 0.1, 0.2, 0.3, and 0.5 g of ferrihydrite powder with 0.6 mL of fungal suspension to form aggregates A1, A2, A3, and A4. Add the aggregates A1, A2, A3, and A4 to the trivalent arsenic ion concentration of 200mg L -1 In the arsenic-containing wastewater, the natural pH was 5.5, and the supernatant was taken after shaking culture at 165rpm for 72 hours to detect the concentration of trivalent arsenic ions.

[0053] Group B: take the suspension of Penicillium chrysogenum with a volume of 0.2, 0.4, 0.6, 0.8mL (i.e. 5%, 10%, 15%, 20% (v / v)) Add 0.3 g of ferrihydrite powder to the bacterial suspension to form aggregates B1, B2, B3, and B4. Add the aggregates B1, B2, B3, and B4 respectively to the concentration of trivalent arsenic ions at 200 mg·L -1 In the arsenic-containing wastewater, the natural pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com