Energy-saving phase-transformation anti-cracking polymer special mortar and preparation method thereof

A kind of polymer and special technology, applied in the field of building materials, can solve the problems of increasing cost and not effectively improving the anti-cracking performance of mortar, and achieve the effects of low cost, improved storage stability and good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

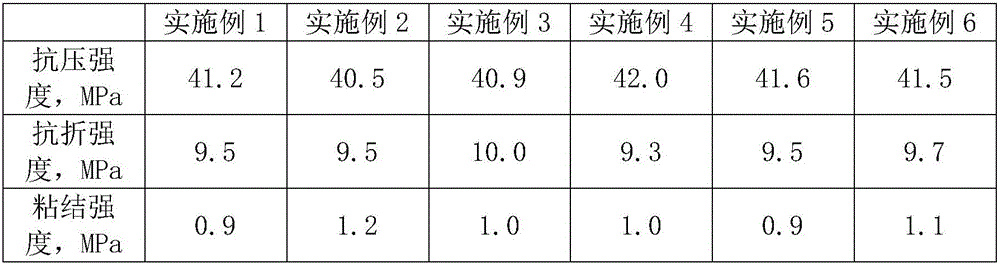

Examples

Embodiment 1

[0035] An energy-saving phase-change anti-crack polymer special mortar, comprising the following components in parts by weight:

[0036] 20 parts of cement, 40 parts of river sand,

[0037] 30 parts of fly ash, 3 parts of carboxy-modified styrene-butadiene latex,

[0038] 4 parts of epoxy resin modified styrene-acrylic latex, 10 parts of paraffin wax,

[0039] 10 parts of expanded perlite, 3 parts of polypropylene fiber,

[0040] 1 part of water reducer, 0.5 part of retarder,

[0041] 2 parts of silane coupling agent, 40 parts of deionized water;

[0042] Its preparation method comprises the following steps:

[0043] (1) Mix expanded perlite and paraffin evenly in a vacuum reactor at 120°C, then slowly open the vent valve, reduce the vacuum in the vacuum reactor to normal pressure, and let it stand for 1 hour to obtain expanded pearls adsorbed with paraffin rock;

[0044] (2) Mix the expanded perlite adsorbed with paraffin, polypropylene fiber, silane coupling agent, car...

Embodiment 2

[0047] An energy-saving phase-change anti-crack polymer special mortar, comprising the following components in parts by weight:

[0048] 40 parts of cement, 60 parts of river sand,

[0049] 50 parts of fly ash, 8 parts of carboxy-modified styrene-butadiene latex,

[0050] 10 parts of epoxy resin modified styrene-acrylic latex, 18 parts of paraffin wax,

[0051] 20 parts of expanded perlite, 5 parts of polypropylene fiber,

[0052] 2 parts of water reducer, 1.2 parts of retarder,

[0053] 3 parts of silane coupling agent, 60 parts of deionized water;

[0054] Its preparation method comprises the following steps:

[0055] (1) Mix expanded perlite and paraffin in a vacuum reactor at 200°C, then slowly open the vent valve, reduce the vacuum in the vacuum reactor to normal pressure, and let it stand for 2 hours to obtain expanded pearls adsorbed with paraffin rock;

[0056] (2) Mix the expanded perlite adsorbed with paraffin, polypropylene fiber, silane coupling agent, carbox...

Embodiment 3

[0059] An energy-saving phase-change anti-crack polymer special mortar, comprising the following components in parts by weight:

[0060] 25 parts of cement, 45 parts of river sand,

[0061] 35 parts of fly ash, 4 parts of carboxy-modified styrene-butadiene latex,

[0062] 5 parts of epoxy resin modified styrene-acrylic latex, 12 parts of paraffin wax,

[0063] 12 parts of expanded perlite, 3.5 parts of polypropylene fiber,

[0064] 1.2 parts of water reducer, 0.7 parts of retarder,

[0065] 2.2 parts of silane coupling agent, 45 parts of deionized water;

[0066] Its preparation method comprises the following steps:

[0067] (1) Mix expanded perlite and paraffin evenly in a vacuum reactor at 140°C, then slowly open the vent valve, reduce the vacuum in the vacuum reactor to normal pressure, and let it stand for 1.2 hours to obtain an expanded wax adsorbed with paraffin. Perlite;

[0068](2) Mix the expanded perlite, polypropylene fiber, silane coupling agent, carboxyl-mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com