Water-blown inorganic hybrid melamine polyurethane rigid foam material and manufacturing method thereof

A technology of hybrid melamine polyurethane and hybrid melamine, which is applied in the field of water-foamed polyurethane rigid foam materials and its manufacturing, can solve the problems of high viscosity, high thermal conductivity, and poor fluidity of the system, and achieve high temperature resistance and flame retardancy Improvement of performance and improvement of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

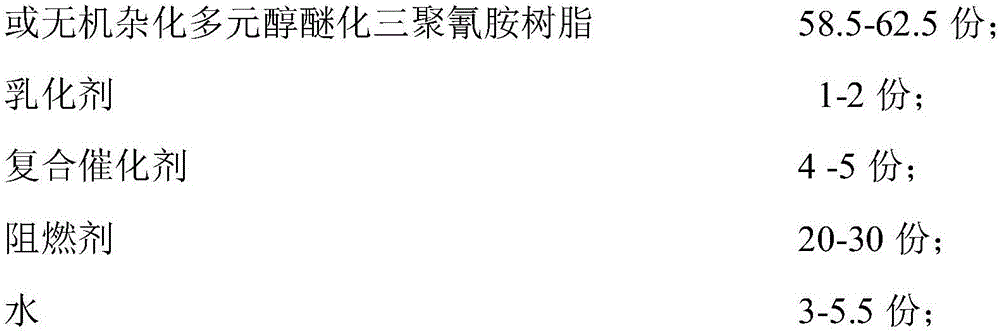

[0045] Water foaming inorganic hybrid melamine polyurethane rigid foam material, the material is a rigid foam material formed by foaming inorganic hybrid melamine polyurethane polyether and polymerized isocyanate, inorganic hybrid melamine polyurethane polyether, in parts by weight, The formula is as follows:

[0046]

[0047] The emulsifier is hard foam silicone oil.

[0048] The composite catalyst is potassium acetate and pentamethyldiethylenetriamine.

[0049] The flame retardant is phosphoric acid ester, the phosphoric acid ester is tris(1-chloro-2-propyl) phosphate, and the viscosity of the phosphoric acid ester is 290 Pa·s.

[0050] Inorganic hybrid melamine resin polyol is specifically boron hybrid melamine resin propylene glycol, and its molecular structural formula and preparation method are as follows:

[0051]

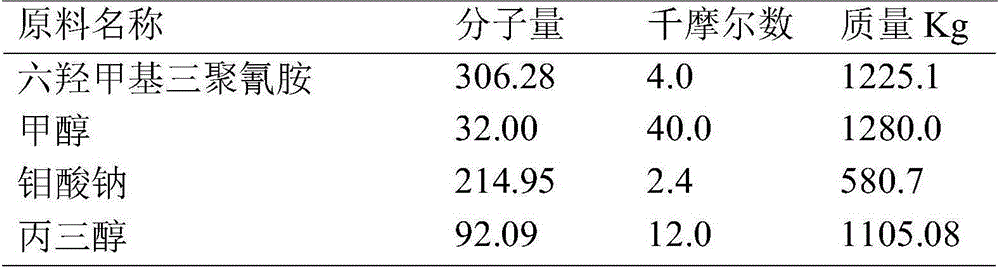

[0052] Raw material ratio:

[0053]

[0054]

[0055] (1) etherification reaction

[0056] Add hexamethylol melamine and methanol into the rea...

Embodiment 2

[0073] Water foaming inorganic hybrid melamine polyurethane rigid foam material is a rigid foam material formed by foaming inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate, characterized in that:

[0074] Water foaming inorganic hybrid melamine polyurethane rigid foam material is a rigid foam material formed by foaming inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate, characterized in that:

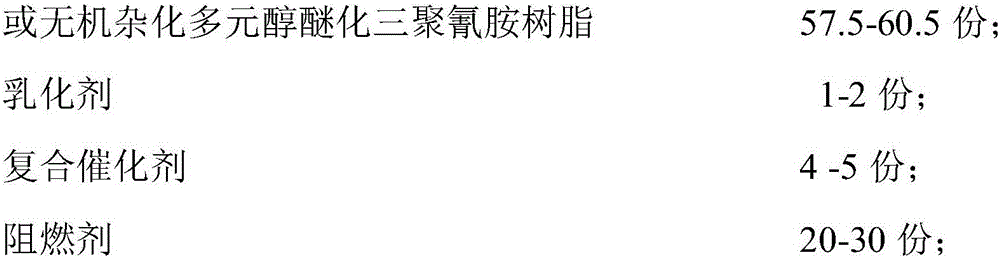

[0075] Described inorganic hybrid melamine polyurethane combination polyether, by weight ratio, formula is as follows:

[0076]

[0077] The emulsifier is hard foam silicone oil.

[0078] The composite catalyst is pentamethyldiethylenetriamine, 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, trimethyl-N-2 hydroxypropyl hexanoic acid and dilauric acid di Butyl tin.

[0079] The flame retardant is phosphoric acid ester, the phosphoric acid ester is tris(2,3-dichloropropyl) phosphate, and the viscosity o...

Embodiment 3

[0103] Water foaming inorganic hybrid melamine polyurethane rigid foam material is a rigid foam material formed by foaming inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate, characterized in that:

[0104] Water foaming inorganic hybrid melamine polyurethane rigid foam material is a rigid foam material formed by foaming inorganic hybrid melamine polyurethane combined with polyether and polymerized isocyanate, characterized in that:

[0105] Described inorganic hybrid melamine polyurethane combination polyether, by weight ratio, formula is as follows:

[0106]

[0107] The emulsifier is hard foam silicone oil.

[0108] The composite catalyst is 1,3,5-tris(dimethylaminopropyl)hexahydrotriazine, triethylenediamine and N,N-dimethylaniline.

[0109] The flame retardant is phosphoric acid ester, and the phosphoric acid ester is tris(1-chloro-2-propyl) phosphate and tris(2,3-dichloropropyl) phosphate, and the viscosity of the phosphoric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com