High-gloss water-based amino baking paint and preparation method thereof

An amino baking varnish, high-gloss technology, applied in the direction of coating, etc., to achieve the effect of excellent mechanical properties, high application value, and reasonable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

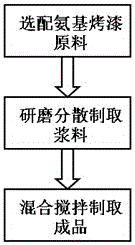

[0015] figure 1 It is a process step diagram of a method for preparing a high-gloss water-based amino baking varnish according to an embodiment of the present invention; the amino baking varnish includes the following raw material components: water-based hydroxyl acrylic acid modified saturated polyester resin, low methyl etherified melamine resin curing agent, dimethylethanolamine, Diethylene glycol monobutyl ether, compound pigment, wetting agent, dispersant, LF-1207 anti-flash rust agent, BYK-141 defoamer, BYK-300 leveling agent, deionized water, the preparation method It includes the following steps: a) matching amino baking varnish raw materials, b) grinding and dispersing to prepare slurry, c) mixing and stirring to prepare finished products.

[0016] The high-gloss water-based amino baking varnish mentioned in the present invention uses water-based acrylic modified saturated polyester resin and low methyl etherified melamine resin as film-forming substances, and by dete...

Embodiment 1

[0018] The specific preparation method is as follows:

[0019] a) Choose the raw material of amino baking varnish, and weigh the following raw materials by weight percentage: 30% water-based hydroxyacrylic acid modified saturated polyester resin, 8% low methyl etherified melamine resin curing agent, 1% dimethylethanolamine, 1% diethylene glycol monobutyl ether, 6% compound pigment, 0.2% wetting agent, 0.2% dispersant, 0.1% LF-1207 anti-flash rust agent, 0.1% BYK-141 defoaming agent agent, 0.4% BYK-300 leveling agent, 53% deionized water; the compound pigment is composed of iron oxide red and iron oxide black in a mass ratio of 1:1; the wetting agent is an anionic alkyl Sulfosuccinate; the dispersant is polyacrylic acid sodium salt.

[0020] b) Grinding and dispersing to prepare the slurry, first, 2 / 3 of the water-based hydroxyacrylic acid modified saturated polyester resin weighed in step a) and dimethylethanolamine, compound pigment, wetting agent, Put the dispersant, LF-12...

Embodiment 2

[0023] The specific preparation method is as follows:

[0024] a) Choose the raw material of amino baking varnish, and weigh the following raw materials by weight percentage: 35% water-based hydroxyacrylic acid modified saturated polyester resin, 10% low methyl etherified melamine resin curing agent, 2% dimethylethanolamine, 1.5% diethylene glycol monobutyl ether, 7% compound pigment, 0.3% wetting agent, 0.3% dispersant, 0.2% LF-1207 anti-flash rust agent, 0.2% BYK-141 defoaming agent agent, 0.5% BYK-300 leveling agent, 43% deionized water; the compound pigment is composed of iron oxide red and iron oxide black in a mass ratio of 1:1; the wetting agent is an anionic alkyl Sulfosuccinate; the dispersant is polyacrylic acid sodium salt.

[0025] b) Grinding and dispersing to prepare the slurry, first, 2 / 3 of the water-based hydroxyacrylic acid modified saturated polyester resin weighed in step a) and dimethylethanolamine, compound pigment, wetting agent, Put the dispersant, LF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com