Adhesive composition and surface protection film

A composition and adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of reduced reoperability, difficulty in re-attaching, easy to produce residual glue, etc., and reach the pot life Effects of long life, excellent durability and reworkability, and excellent antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] In order to avoid an increase in the viscosity of the pressure-sensitive adhesive composition, each monomer used for the preparation of the copolymer of the main component, it is preferable to reduce the amount of the polyfunctionality (difunctionality or more) monomer which can function as a crosslinking agent as much as possible. In particular, (D) polyalkylene glycol mono(meth)acrylate monomer is preferably used because the corresponding diester component is a di(meth)acrylate of a difunctional monomer.

[0109] The copolymer is preferably an acrylic polymer, and preferably contains (meth)acrylate monomer or (meth)acrylic acid, (meth)acrylic acid, (meth)acrylic acid, base) acrylic monomers such as acrylamides.

[0110] In addition, the acid value of the acrylic polymer is preferably from 0.01 to 8.0. Thereby, the contamination property can be improved, and the performance of preventing the generation of adhesive residue can be improved.

[0111] Here, the "acid val...

Embodiment 1

[0123] Nitrogen gas was introduced into a reaction device equipped with a stirrer, a thermometer, a reflux cooler, and a nitrogen introduction pipe, and the air in the reaction device was replaced with nitrogen gas. Then, add 100 parts by weight of 2-ethylhexyl acrylate, 3.0 parts by weight of 8-hydroxyoctyl acrylate, 0.2 parts by weight of acrylic acid, polypropylene glycol monoacrylate (the alkylene that constitutes the polyalkylene glycol chain) in the reaction device. The average number of repeating units of oxy groups n=12, the absorbance in the state of 25% aqueous solution is 0.03) 10 parts by weight, 5 parts by weight of N-vinylpyrrolidone and 60 parts by weight of solvent (ethyl acetate). Then, 0.1 weight part of azobisisobutyronitrile was dripped as a polymerization initiator over 2 hours, and it was made to react at 65 degreeC for 6 hours, and the acrylic acid copolymer solution used in Example 1 with a weight average molecular weight of 500,000 was obtained. A part...

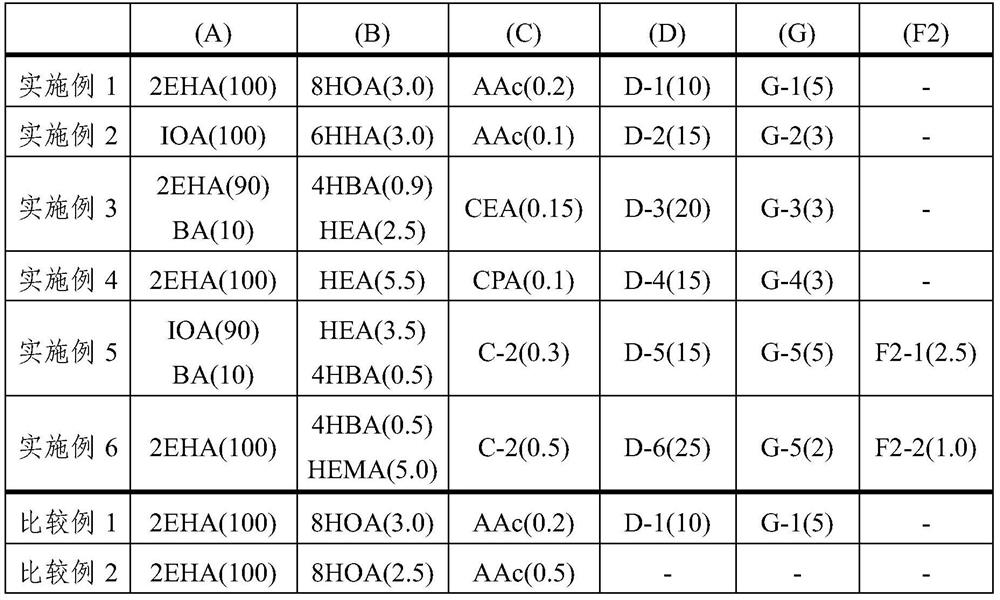

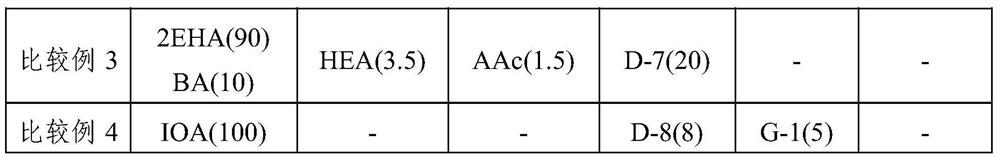

Embodiment 2~6 and comparative example 1~4

[0125] Except that the composition of the monomer is as described in (A) to (D), (G) and (F2) of Table 1, in the same manner as the above-mentioned acrylic acid copolymer solution used in Example 1, obtained in Acrylic copolymer solution used in Examples 2-6 and Comparative Examples 1-4.

[0126]

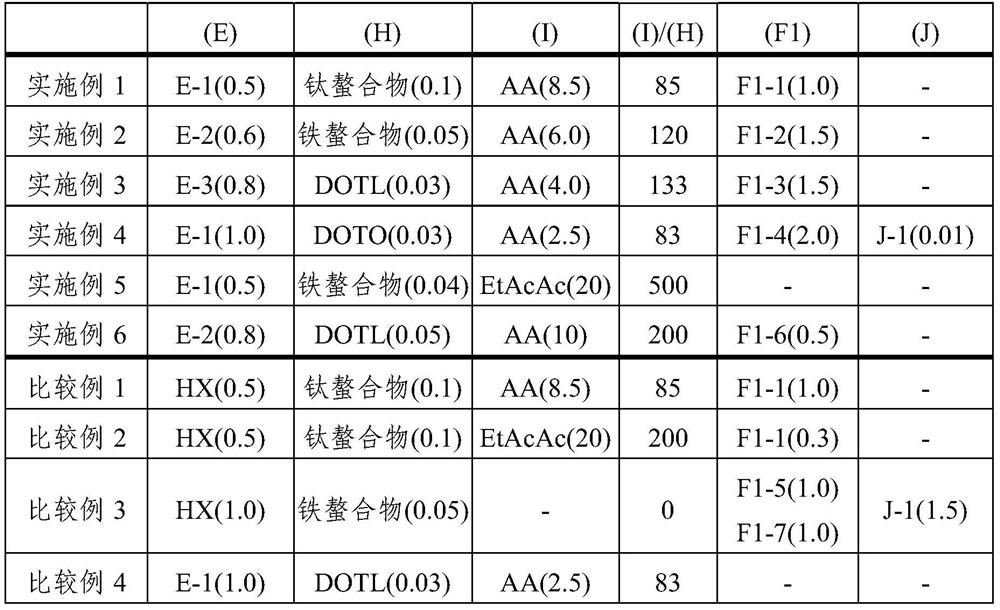

[0127] [Example 1]

[0128] For the acrylic acid copolymer solution of Example 1 prepared above, add 1.0 parts by weight of 1-octylpyridinium hexafluorophosphate, 8.5 parts by weight of acetylacetone and stir, then add the isocyanurate of pentamethylene diisocyanate compound 0.5 parts by weight of titanium triacetylacetonate and 0.1 parts by weight of titanium triacetylacetonate were stirred and mixed to obtain the adhesive composition of Example 1. After coating this adhesive composition on a release film made of a silicone resin-coated polyethylene terephthalate (PET) film, the solvent was removed by drying at 90°C to obtain an adhesive layer Adhesive sheets with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com