Method for accurately measuring selenium content in wine

A technology for accurate determination and content, applied in the field of analytical chemistry, can solve problems such as equipment or personnel damage, and achieve the effects of high accuracy, good repeatability, and simple and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

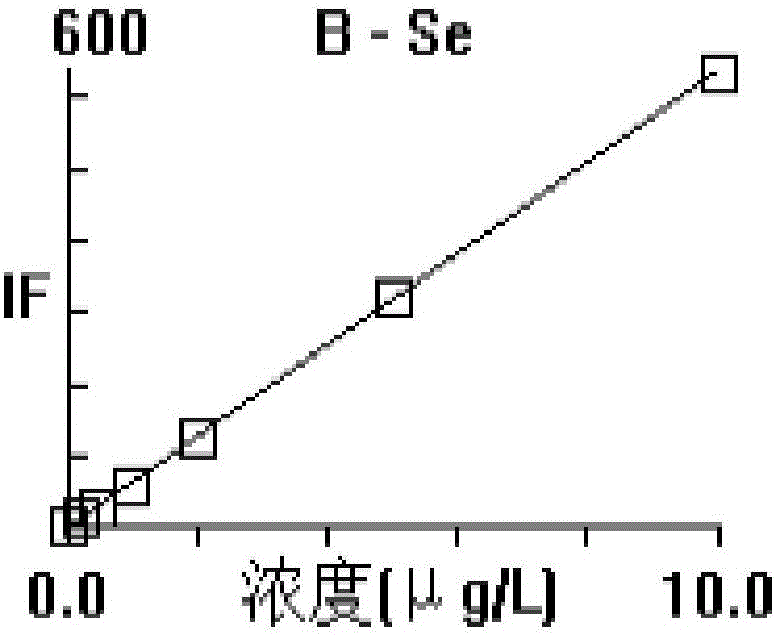

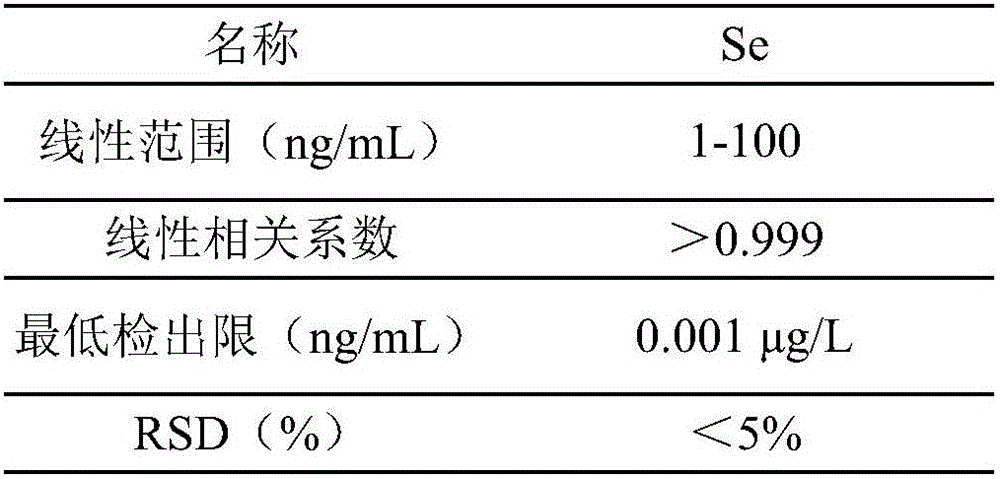

Image

Examples

Embodiment 1

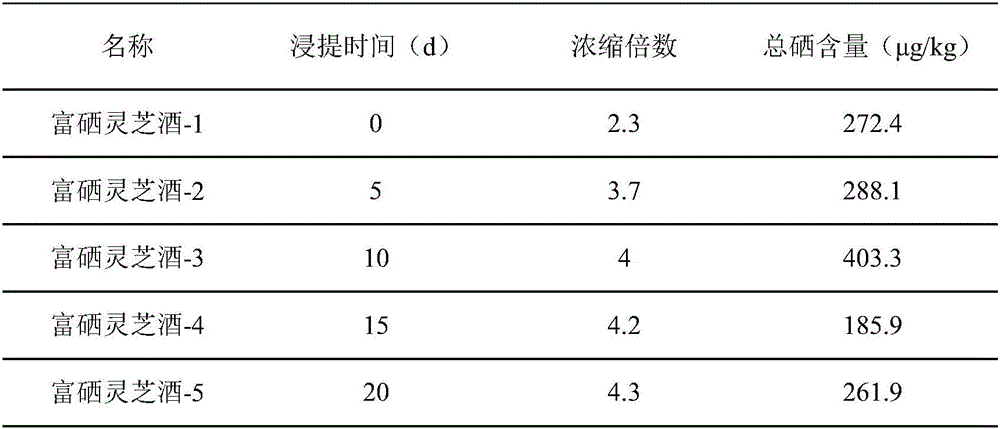

[0026] Determination of total selenium content in embodiment 1 selenium-enriched ganoderma lucidum wine

[0027] The steps of the pretreatment method for the determination of total selenium content in selenium-enriched Ganoderma lucidum wine were optimized. The optimization process and results are as follows:

[0028] Measure 50 mL of wine sample into a conical flask, heat it in a water bath at 80°C for 1 to 2 hours, and take the end point of the water bath when the wine smell is basically gone, add 8 mL of nitric acid, shake well and let it stand for 30 minutes, then add 2 mL of hydrogen peroxide drop by drop, every Drop 0.5mL, shake well after each drop and let stand for 2min, cold digest for 6h, heat digest at 80°C for 30min, heat digest at 90°C for 30min, heat digest at 100°C for 1-2h until clarification, add 5mL after cooling After reducing with hydrochloric acid for 3 hours, transfer the solution in the Erlenmeyer flask to a 25mL colorimetric tube for testing.

[0029] ...

example 2

[0039] Determination of total selenium content in example 2 selenium-enriched wheat wine

[0040] The implementation conditions are the same as those in Example 1, and Table 4 and Table 5 are the measurement results of total selenium in selenium-enriched wheat wine and the measurement results of standard addition recovery respectively.

[0041] Table 4 Determination results of total selenium in wine samples

[0042]

[0043]

[0044] Table 5 The recovery and determination results of selenium-enriched wheat wine

[0045]

[0046] It can be seen from Table 5 that the recovery rate of the addition of selenium-enriched wheat wine is 79% to 88%, and the recovery effect is ideal, indicating that the pretreatment method and determination method are reliable.

[0047] To sum up, the present invention can fully digest the organic matter in the wine and fully reduce the selenium-containing compounds, so as to facilitate the detection of the total selenium content. This is of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com