Graphene electrothermal material and application thereof

A technology of electrothermal materials and graphene, which is applied in the direction of heating element materials, electrothermal devices, ohmic resistance heating, etc., can solve the problem that the energy saving of electrothermal materials is not very good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

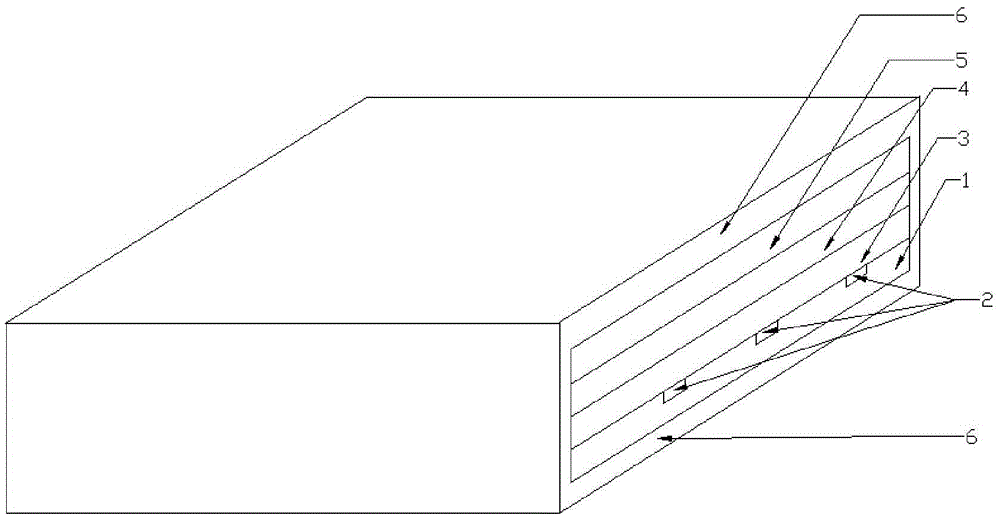

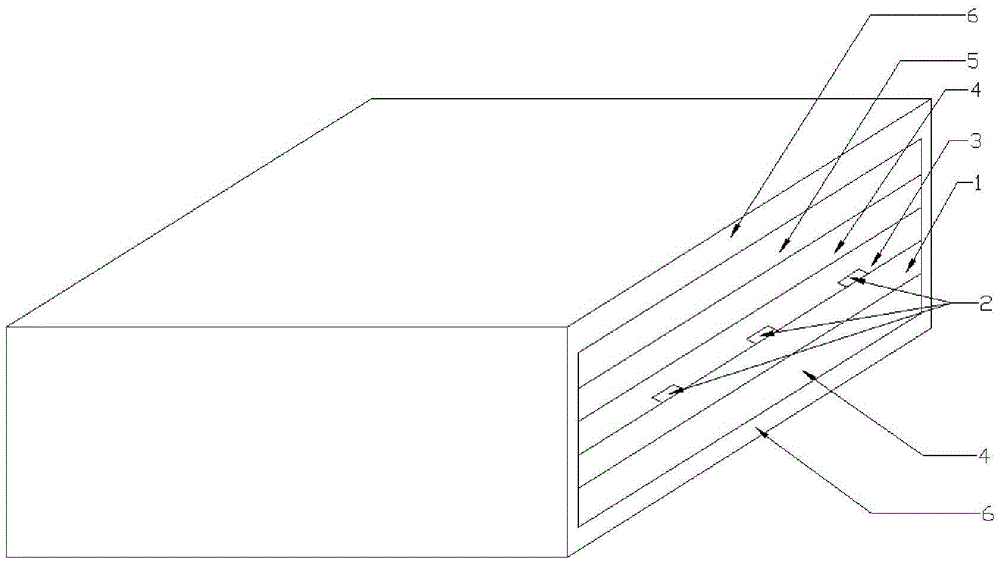

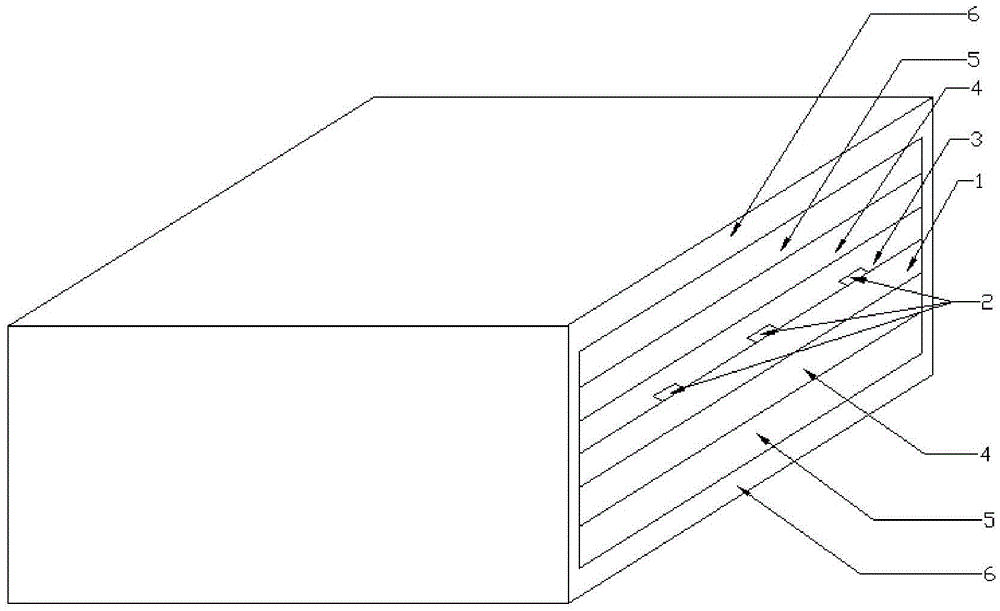

Image

Examples

Embodiment 1

[0106] (1) Graphene A and carbon fiber are mixed with a certain amount of dispersant 1wt% styrene-maleic anhydride copolyester, 0.1wt% silicone oil and 2wt% aminopropyl trimethoxy according to the ratio of 0.5:1 Silane was dissolved in ethanol to obtain a graphene composite slurry with a concentration of 2 mg / mL.

[0107] (2) Spray the above-mentioned slurry on the surface of ship pipelines, satellite antennas, aircraft, automobile parts, etc., and fully dry.

[0108] (3) Connect the above-mentioned dried heating film to a low-voltage circuit.

[0109] (4) Spray a layer of heat conduction protective layer on the surface of the heating film.

[0110] This embodiment can be applied to the deicing of pipelines, instruments, and parts of ships, vehicles, aircraft, etc. working in a low-temperature environment. The purpose of rapid surface heating can be realized under the condition of small voltage (1-5V).

Embodiment 2

[0112] (1) Graphene A and carbon fiber are uniformly mixed in a ratio of 2:1, with a certain amount of dispersant 1wt% styrene-maleic anhydride copolyester, 0.1wt% silicone oil and 2wt% aminopropyl trimethyl Oxysilane was dissolved in ethanol to obtain a graphene composite slurry with a concentration of 10 mg / mL.

[0113] (2) Spray the above-mentioned slurry on the surface of ship pipelines, satellite antennas, aircraft, automobile parts, etc., and fully dry.

[0114] (3) Connect the above-mentioned dried heating film to a low-voltage circuit.

[0115] (4) Spray a layer of heat conduction protective layer on the surface of the heating film.

[0116] This embodiment can be applied to the deicing of pipelines, instruments, and parts of ships, vehicles, aircraft, etc. working in a low-temperature environment. The purpose of rapid surface heating can be realized under the condition of small voltage (1-5V).

Embodiment 3

[0118] (1) Graphene A and carbon fiber are evenly compounded with a ratio of 3:1, adding 0.5wt% far-infrared finishing agent (titanium oxide), and adding 1wt% styrene-maleic anhydride copolyester, 0.1wt% Silicone oil and 2% aminopropyltrimethoxysilane were fully dispersed in water to obtain a 100 mg / mL slurry.

[0119] (2) Press and weld copper foil strips at both ends of the fiber fabric as electrodes.

[0120] (3) Apply the slurry evenly on the surface of the fiber fabric to form a film with a thickness of 0.1mm, and form a graphene radiation heating film after drying or drying.

[0121] (4) Degassing, followed by primary packaging with thermally conductive plastic material.

[0122] (5) Cutting and milling the target to obtain wiring solder joints, and use insulating materials to seal the joints after wiring.

[0123] (6) After laminating a phase-change material (sodium acetate) film with a thickness of 0.5mm on the outside of the heat-conducting plastic, use an insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com