Preparation method for high-calcium instant bean flour of assisted nutrition complementary food

A technology of instant soybean powder and nutritional supplement, applied in the field of soybean product processing, can solve the problems of high calcium content, low absorption utilization rate, high absorption utilization rate, etc., and achieve the effect of low solubility, simple equipment and high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

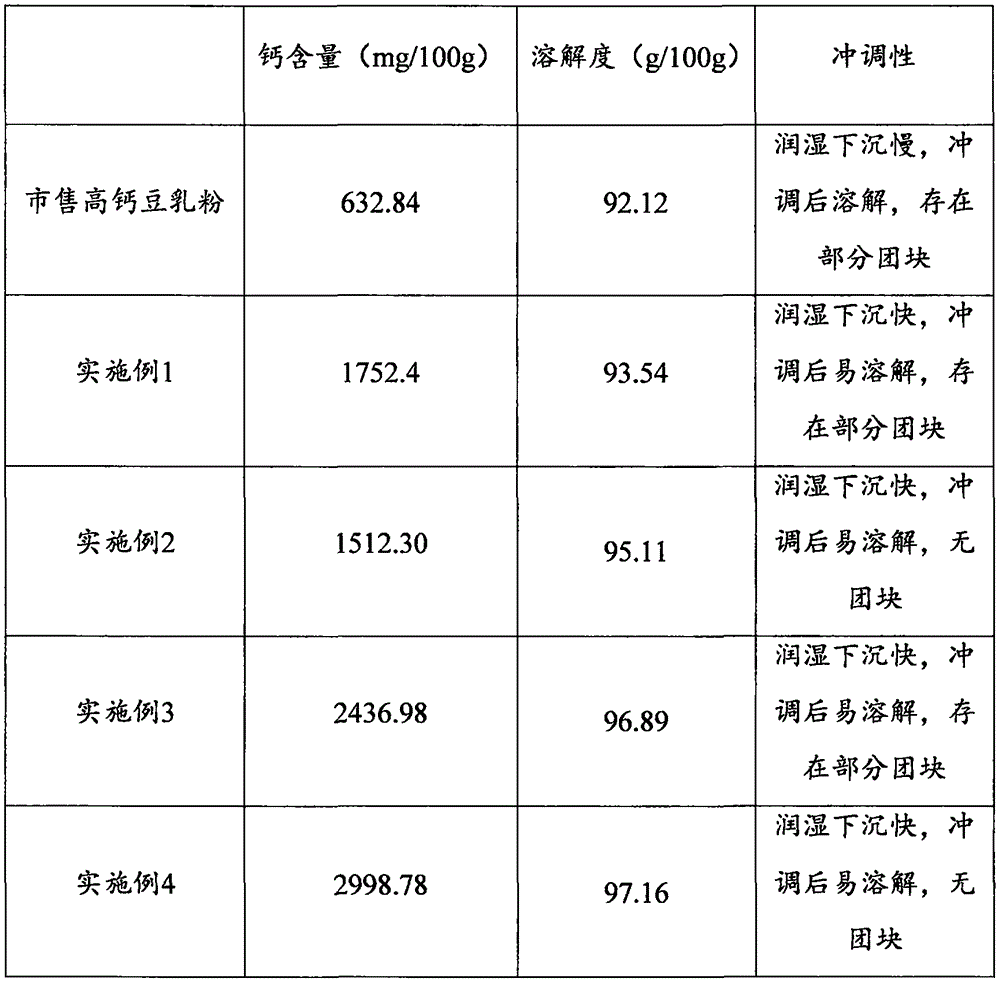

Examples

preparation example Construction

[0024] A method for preparing high-calcium instant bean powder used as food supplement nutritional supplements, the method comprising the following steps: (1) After soybeans are selected and removed, after the soybeans are selected and removed, dried and peeled, the concentration is 0.5%. NaHCO 3 After soaking beans in aqueous solution for 12 hours, dry them in an oven at 85°C, then use a refiner to add 8 times of boiling water to refine the pulp, and boil the soybean milk at 91°C-95°C for 10 minutes to obtain a mixture of pulp and residue; (2) Filter the residue part NaHCO for soymilk 3Adjust pH to 8.0, add superfine calcium carbonate, citric acid, white granulated sugar, and malt syrup to prepare, and the added amount of said superfine calcium carbonate is 3.75%-7.50%; (3) place the prepared soybean milk in an ultrasonic microwave combined reactor In the middle, ultrasonic-microwave joint solubilization treatment is carried out, the ultrasonic time is 10-25min, the ultrason...

Embodiment 1

[0028] After the soybeans have been selected and removed from impurities, after the soybeans have been selected to remove impurities, dried and peeled, they are treated with NaHCO with a concentration of 0.5%. 3 After soaking beans in aqueous solution for 12 hours, dry them in an oven at 85°C, then use a refiner to add 8 times the amount of boiling water to refine the pulp, and boil the soybean milk at 91°C for 10 minutes to obtain a mixture of pulp and residue; filter the residue part of the soybean milk with NaHCO 3 Adjust the pH to 8.0, add ultra-fine calcium carbonate, citric acid, white sugar, and malt syrup to prepare, and the added amount of ultra-fine calcium carbonate is 3.75%; put the prepared soybean milk in an ultrasonic microwave combined reactor, and carry out ultrasonic-microwave combined multiplication Dissolution treatment, ultrasonic time 10min, ultrasonic power 200W, microwave time 45s, microwave power 350W, processing temperature 75°C; homogenize the soymilk...

Embodiment 2

[0030] After the soybeans have been selected and removed from impurities, after the soybeans have been selected to remove impurities, dried and peeled, they are treated with NaHCO with a concentration of 0.5%. 3 After soaking beans in aqueous solution for 12 hours, dry them in an oven at 85°C, then use a refiner to add 8 times the amount of boiling water to refine the pulp, boil the soybean milk at 95°C for 10 minutes, and obtain a mixture of pulp and residue; filter the residue part of the soybean milk with NaHCO 3 Adjust the pH to 8.0, add ultra-fine calcium carbonate, citric acid, white granulated sugar, and malt syrup to prepare, wherein the amount of ultra-fine calcium carbonate added is 7.50%; (3) place the prepared soybean milk in an ultrasonic microwave combined reactor, and perform ultrasonic- Microwave joint solubilization treatment, ultrasonic time 25min, ultrasonic power 400W, microwave time 60s, microwave power 350W, treatment temperature 75°C; the soybean milk tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com