A cobalt complex recovery method for simultaneous flue gas desulfurization and denitrification by cobalt ammonium absorbent

A technology of desulfurization, denitrification, and recovery methods, which is applied in the field of recovery and regeneration of cobalt complexes, can solve the problems of low regeneration rate of complex absorbents, complex absorption and regeneration, etc., and achieve low operating costs, high recovery rates, and easy operation and maintenance. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

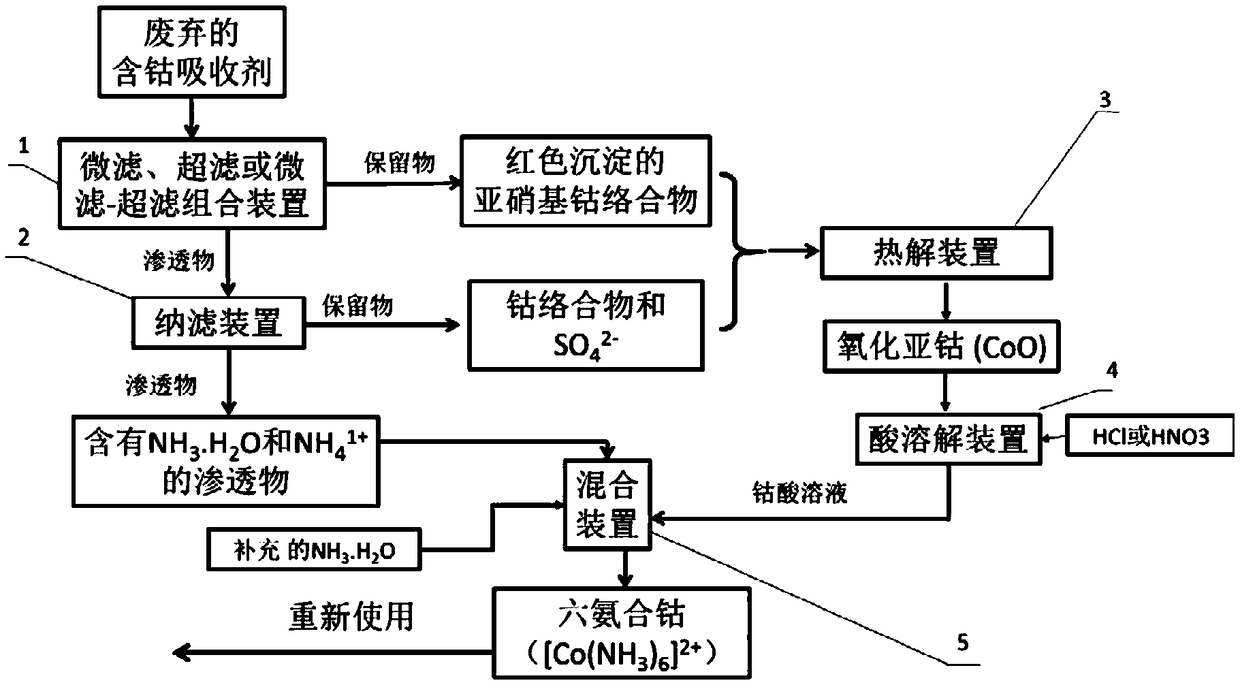

[0026] The membrane used in the ultrafiltration device 1 is an ultrafiltration roll-type composite membrane membrane module, and its operating pressure is 0.2MPa. The nanofiltration device uses a polyamide nanofiltration roll-type composite membrane membrane module, and the nanofiltration operating pressure is 0.8MPa. The operating temperature in the pyrolysis unit 3 was 950°C. The acid solution added to the dissolving device 4 is hydrochloric acid HCl with a concentration of 37%, and the pH value of the solution in the mixing device is 11. Through this process flow, the invalid trivalent [Co(NH 3 ) 6 ] 3+ Recovery and reduction to divalent [Co(NH 3 ) 6 ] 2+ Used again as absorbent to absorb SO 2 and NOx, the discarded [Co(NH 3 ) 6 ] 3+ into [Co(NH 3 ) 6 ] 2+ The cobalt recovery rate is higher than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com