Positively charged graphene oxide/quaternized chitosan composite nanofiltration membrane prepared through layer-by-layer self-assembly and preparation method of nanofiltration membrane

A technology of quaternized chitosan and layer-by-layer self-assembly, applied in the field of separation membranes, can solve the problems of large impact on membrane performance, insufficient environmental protection polyacrylamide, complicated preparation steps, etc., and achieves good interception effect and hydrophilicity. And the effect of good anti-fouling performance and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

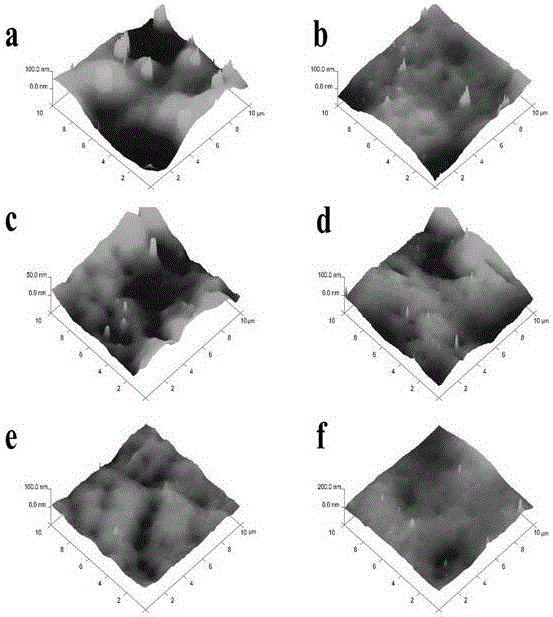

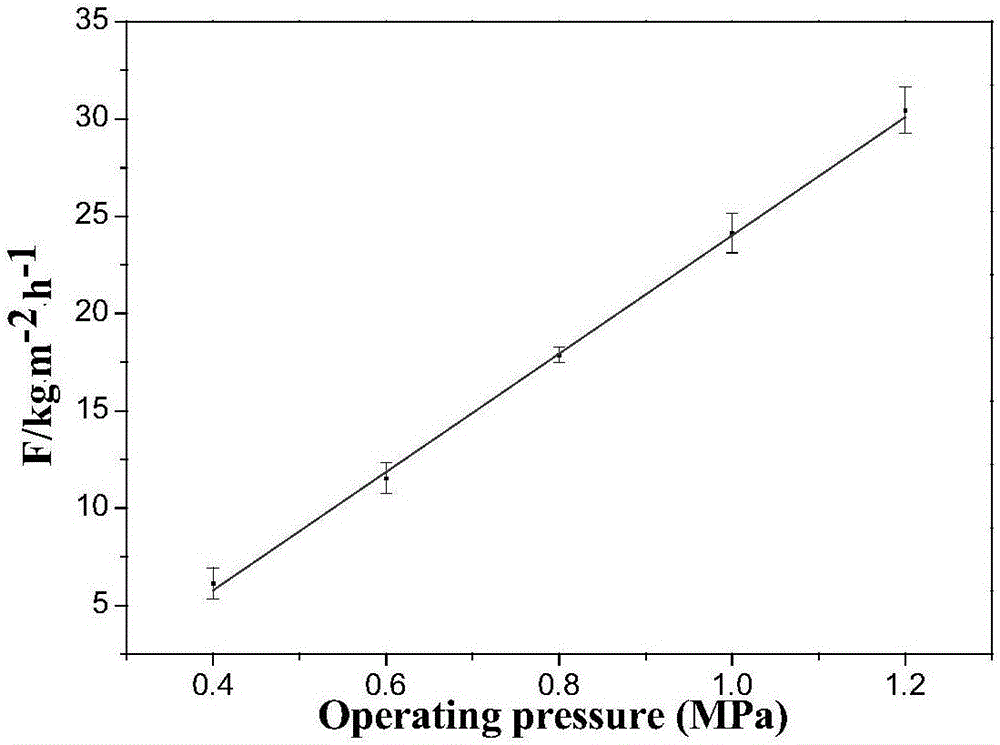

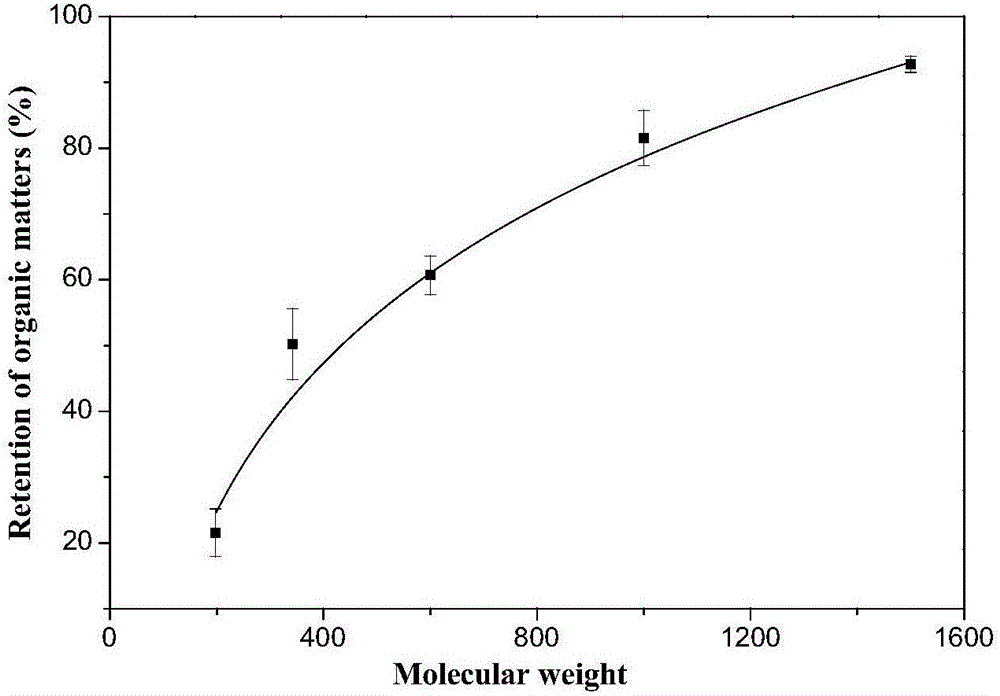

[0023] The refined HTCC sample was dissolved in deionized water to prepare a HTCC cationic casting solution with a mass concentration of 5 mg / mL. Weigh the graphite oxide sample and dissolve it in deionized water. Under the condition of 60W, ultrasonically peel it for 3h, let it stand overnight, and then take the upper layer dispersion to make the mass concentration of 0.25mg / mL, 0.5mg / mL, 0.75mg / mL, 1.0mg / mL, 1.5mg / mL GO anion casting solution, adjust the pH to about 4 with acid and alkali. Take 6 polyethersulfone ultrafiltration membranes, soak them in the cationic polyelectrolyte solution for 15 minutes, and then wash them in deionized water for 1 minute to remove excess polyelectrolyte on the surface of the composite membrane. It was then soaked in an anionic polyelectrolyte solution for 20 min, and then washed in deionized water for 1 min to complete a double layer. Repeat the above steps to prepare 1.5, 2.5, 3.5, 4.5, 5.5, 6.5 double layer composite membranes. The obta...

Embodiment 2

[0026]The refined HTCC sample was dissolved in deionized water to prepare a HTCC cationic casting solution with a mass concentration of 5 mg / mL. Weigh the graphite oxide sample and dissolve it in deionized water. Under the condition of 60W, it will be ultrasonically stripped for 3h, and it will be left standing overnight. pH to 4. Take 6 pieces of polyethersulfone ultrafiltration membranes, soak 6 pieces in cationic polyelectrolyte solution for 15 minutes, and then wash in deionized water for 1 minute to remove excess polyelectrolyte on the surface of the composite membrane. It was then soaked in an anionic polyelectrolyte solution for 20 min, and then washed in deionized water for 1 min to complete a double layer. Repeat the above steps to complete the preparation of 1.5, 2.5, 3.5, 4.5, 5.5, 6.5 double layers soaked in the cationic solution first. The obtained wet film was placed at 50°C for solvent evaporation for 30 min. Then, soak the 6 pieces of dry film in the cross-l...

Embodiment 3

[0029] The refined HTCC sample was dissolved in deionized water to prepare a HTCC cationic casting solution with a mass concentration of 5 mg / mL. Weigh the graphite oxide sample and dissolve it in deionized water. Under the condition of 60W, it will be ultrasonically stripped for 3h, and it will be left standing overnight. pH to 4. Take 4 pieces of polyethersulfone ultrafiltration membranes, soak 4 pieces in the cationic polyelectrolyte solution for 15 minutes, and then wash in deionized water for 1 minute to remove excess polyelectrolyte on the surface of the composite membrane. It was then soaked in an anionic polyelectrolyte solution for 20 min, and then washed in deionized water for 1 min to complete a double layer. Repeat the above steps to complete the preparation of 4.5 bilayers soaked in the cationic solution first. Dry the wet film at 50°C for 30 min, and soak 4 pieces of dry film in an alternating solution of (ECH / ethanol) (0.6mL / 50mL) with a pH of about 8-9 adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com