Reinforcing hollow fiber membrane lining and pretreatment technology

A fiber membrane and reinforced technology, applied in the field of composite membrane material preparation, can solve the problems of complex manufacturing process, undisclosed manufacturing method, complicated textile process, etc., and achieve the effects of simple operation, avoiding peeling and tearing, and obvious processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

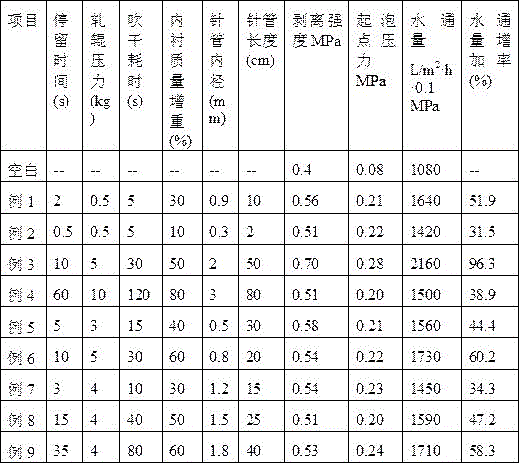

Examples

Embodiment 1

[0039] First, the reinforced lining is immersed in the pretreatment liquid for a period of time through the wire feeding device, and then the excess pretreatment liquid is removed by rollers and shearing and blowing in turn, and finally the reinforced lining is passed through the long and thin needle tube to restore the circular shape.

[0040] The type of reinforced lining is a polyethylene terephthalate fiber braided tube with an outer diameter of 0.9 mm, a weaving density of 20 meshes, and 24 braiding spindles. The pretreatment liquid was dimethylacetamide, whose pH was adjusted to 5.0, and the added polymer was polymethyl methacrylate with a content of 1.0 wt%.

[0041] In the pretreatment process, the residence time of the reinforced lining in the treatment liquid is 2 s, the working pressure of the roll is 0.5 kg, and the air drying takes 5 s; The volume is 30%; the inner diameter of the elongated needle is 0.9 mm and the length is 10 cm.

[0042] The rest of the film-m...

Embodiment 2

[0045] Firstly, the reinforced lining is immersed in the pretreatment solution for a period of time through the wire feeding device, and then the excess pretreatment solution is removed by rollers and shearing and blowing in turn, and finally the reinforced lining is passed through the long and thin needle tube to restore the circular shape.

[0046]The type of reinforced lining is polyamide fiber knitted tube, its outer diameter is 0.3 mm, the weaving density is 10 mesh, and the number of weaving spindles is 8. The pretreatment solution is a mixed solution of dimethylformamide / water, the mixing ratio is 1:1, and its pH is adjusted to 2.0. The added polymers are polymethyl acrylate and polyethyl acrylate, and the contents are 0.1 wt% and 1.0 wt%, respectively. wt%.

[0047] In the pretreatment process, the residence time of the reinforced lining in the treatment liquid is 0.5 s, the working pressure of the roll is 0.5 kg, and the air drying takes 5 s; The volume is 10%; the i...

Embodiment 3

[0051] First, the reinforced lining is immersed in the pretreatment liquid for a period of time through the wire feeding device, and then the excess pretreatment liquid is removed by rollers and shearing and blowing in turn, and finally the reinforced lining is passed through the long and thin needle tube to restore the circular shape.

[0052] The type of reinforced lining is a polyester fiber braided tube with an outer diameter of 2.0 mm, a braiding density of 60 mesh, and a braiding spindle number of 32. The pretreatment liquid is ethylene glycol, whose pH is adjusted to 9.0, and the added polymer is polyethyl acrylate with a content of 5.0 wt%.

[0053] In the pretreatment process, the residence time of the reinforced lining in the treatment liquid is 10 s, the working pressure of the roll is 5.0 kg, and the air drying takes 30 s; The volume is 50%; the inner diameter of the elongated needle is 2.0 mm and the length is 50 cm.

[0054] The rest of the film-making condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

| Bubble point pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com