Activated carbon-cobalt ferrite composition material, preparation method thereof and application to photocatalytic denitrification

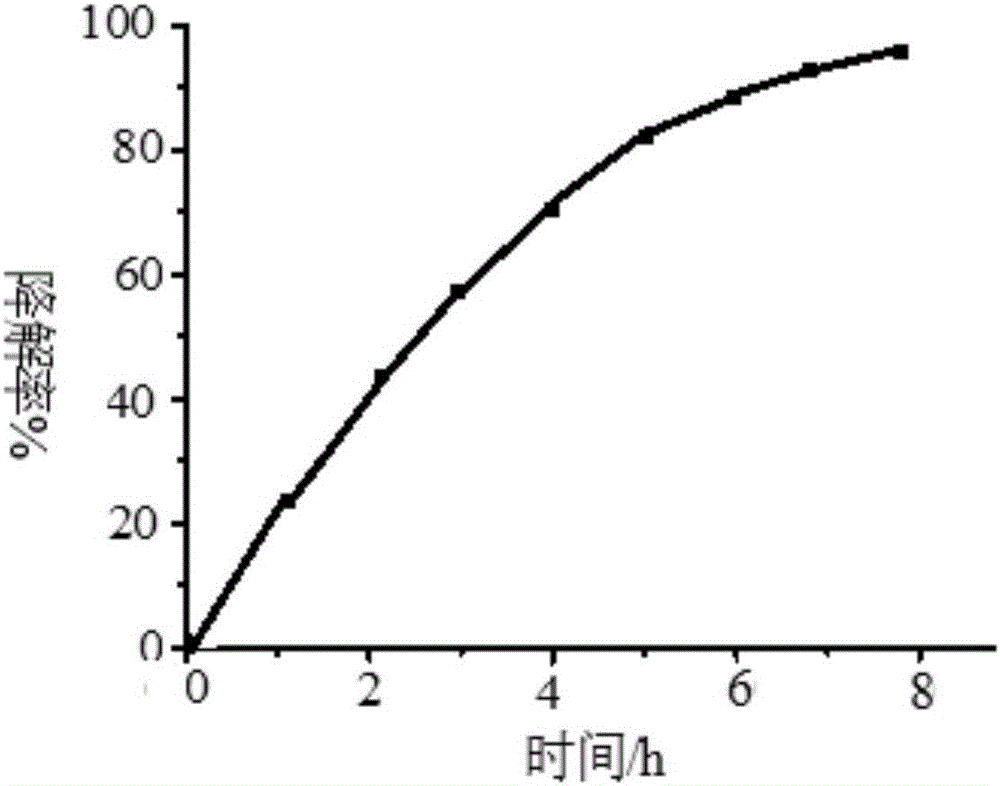

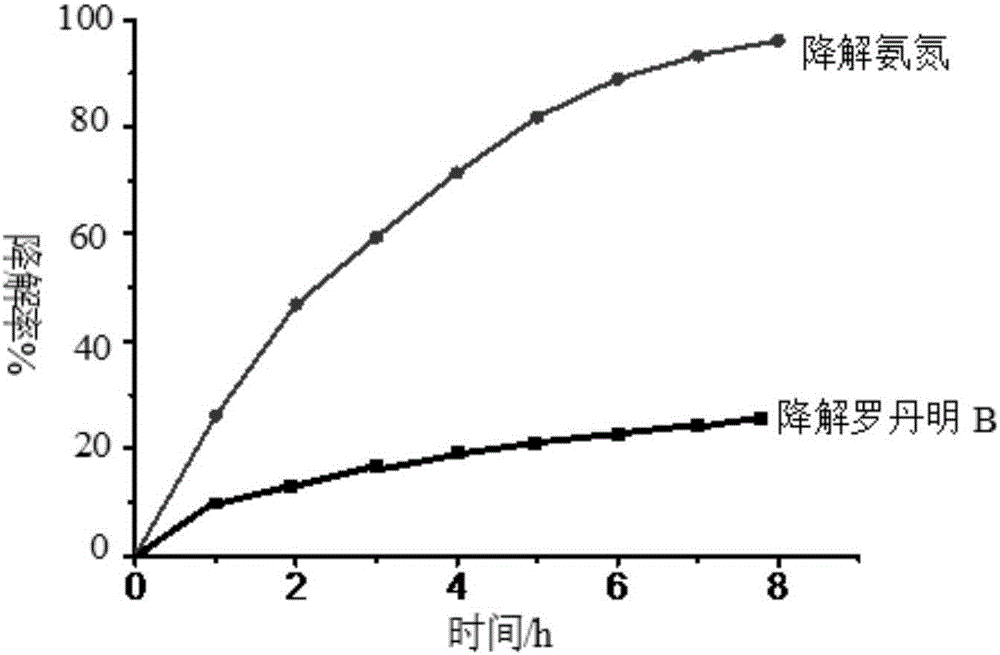

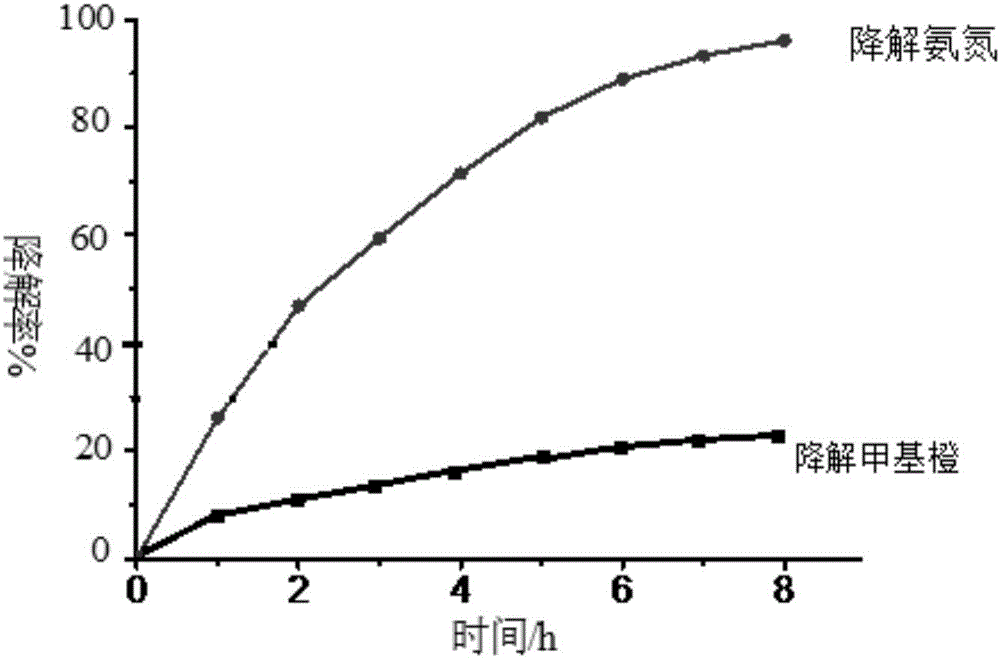

A composite material, cobalt ferrite technology, applied in the field of photocatalysis, can solve the problems of high investment, high cost, lack of selectivity in photocatalytic degradation of ammonia nitrogen, etc., and achieves the effects of cheap and easily available raw materials, simple preparation method, and easily controllable conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides the preparation method of the activated carbon-cobalt ferrite composite material, which includes: dissolving soluble cobalt salt, soluble iron salt and activated carbon in a solvent and mixing them evenly, then adjusting the obtained mixed solution to be alkaline, and then dissolving The mixed solution is reacted at 150-200° C. for 6-10 hours to prepare the activated carbon-cobalt ferrite composite material.

[0028] Further, the molar ratio of the soluble cobalt salt to the soluble iron salt is 1:1-3.

[0029] More preferably, the soluble cobalt salt includes CoCl 2 ·6H 2 O, but not limited to.

[0030] More preferably, described soluble iron salt comprises Fe(NO 3 ) 3 9H 2 O, but not limited to.

[0031] More preferably, the alkaline solution includes NaOH solution, but not limited thereto.

[0032] Further, the mixed solution is reacted at a temperature of 180-200°C for 8-10 hours, then washed with deionize...

Embodiment 1

[0035] Cobalt ferrite (CoFe 2 o 4 ) synthesis: Accurately weigh CoCl at a molar ratio of 1:2 2 ·6H 2 O (1.1897g, 0.005mol), FeCl 3 9H 2 O (2.703g, 0.01mol) was dissolved in 10ml of deionized water, and NaOH (1.9200g, 0.048mol) was accurately weighed and dissolved in 10ml of deionized water. NaOH was slowly added dropwise into the mixed solution under the condition of magnetic stirring, and then the remaining NaOH in the beaker was washed with deionized water and added to the mixed solution. Continue to stir for 20 minutes to make it evenly mixed. At this time, the total volume of the solution is about 50ml. Then add the mixed solution into a 100ml hydrothermal reaction kettle, rinse the residual liquid in the beaker with deionized water, and add it to the reaction kettle, control the total volume of the reaction kettle to about 60ml, and then place the reaction kettle at 180°C Under the conditions of reaction for 8 hours, after cooling, take it out and let it stand, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com