Melamine formaldehyde resin microwave foaming and after-treating device

A technology of melamine formaldehyde resin and post-processing device is applied in the field of melamine formaldehyde resin microwave foaming and post-processing device, which can solve the problems of excessive formaldehyde residue and the like, and achieves improvement of foaming rate and uniformity, improvement of stability, The effect of good mechanical properties and flame retardant and sound-absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

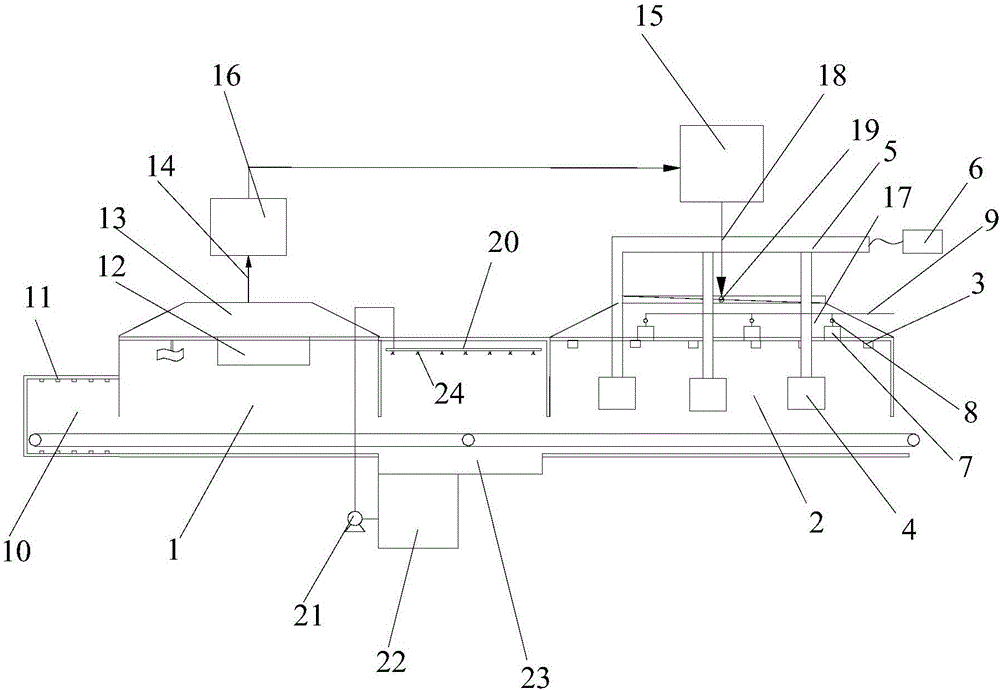

[0026] Such as figure 1 As shown, this embodiment provides a melamine-formaldehyde resin microwave foaming and post-processing device, including a microwave cavity and a curing and drying cavity, and a liquid ammonia spray cavity is arranged between the microwave cavity and the curing and drying cavity body, the top of the liquid ammonia spray chamber is provided with a spray water pipe, the spray pipe is connected to the water pump outlet, the water inlet of the water pump is connected to the circulating water pool through the pipeline, and the circulating water pool is arranged under the liquid ammonia spray chamber, and the liquid ammonia spray A water receiving tank is arranged at the bottom of the ammonia spray chamber, and the water receiving tank is connected with the circulating water pool through a pipeline. The water receiving tank is arranged above the circulating water pool, and a filter device is arranged at the junction of the water receiving tank and the circula...

Embodiment 2

[0039] Such as figure 1As shown, this embodiment provides a melamine formaldehyde resin microwave foaming and post-processing device. In this embodiment, a pre-foaming microwave cavity is provided in front of the microwave cavity, and the microwave frequency in the pre-foaming microwave cavity is 915MHz, and the microwave frequency in the microwave cavity is 915MHz. Since the microwave frequencies of the two are consistent, there is no need to set a microwave backstop between the two.

[0040] Other structures of this embodiment are the same as Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com