Microwave homogeneous hydrothermal synthesis method of magnesium-aluminum hydrotalcite

A homogeneous hydrothermal and hydrotalcite technology, applied in the direction of alumina/hydroxide, etc., can solve the problem of uneven particle size of hydrotalcite, and achieve the effect of simple operation, high reproducibility, and high uniformity of product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Weighing: Weigh 0.03mol of magnesium nitrate hexahydrate, 0.01mol of aluminum nitrate nonahydrate, and 0.18mol of urea;

[0062] (2) Dissolving and subpackaging: Dissolve magnesium nitrate, aluminum nitrate and urea in 100mL deionized water at room temperature, divide into two equal parts, install them in microwave digestion tanks, and seal them;

[0063] (3) Microwave homogeneous hydrothermal synthesis: place the microwave digestion tank in a microwave digestion apparatus, and heat at a set temperature of 130°C for 20 minutes to complete the synthesis;

[0064] (4) Washing and drying: Pour out all the solids and liquids in the microwave tank, wash with deionized water and absolute ethanol respectively, dry in vacuum at 105° C., grind and store.

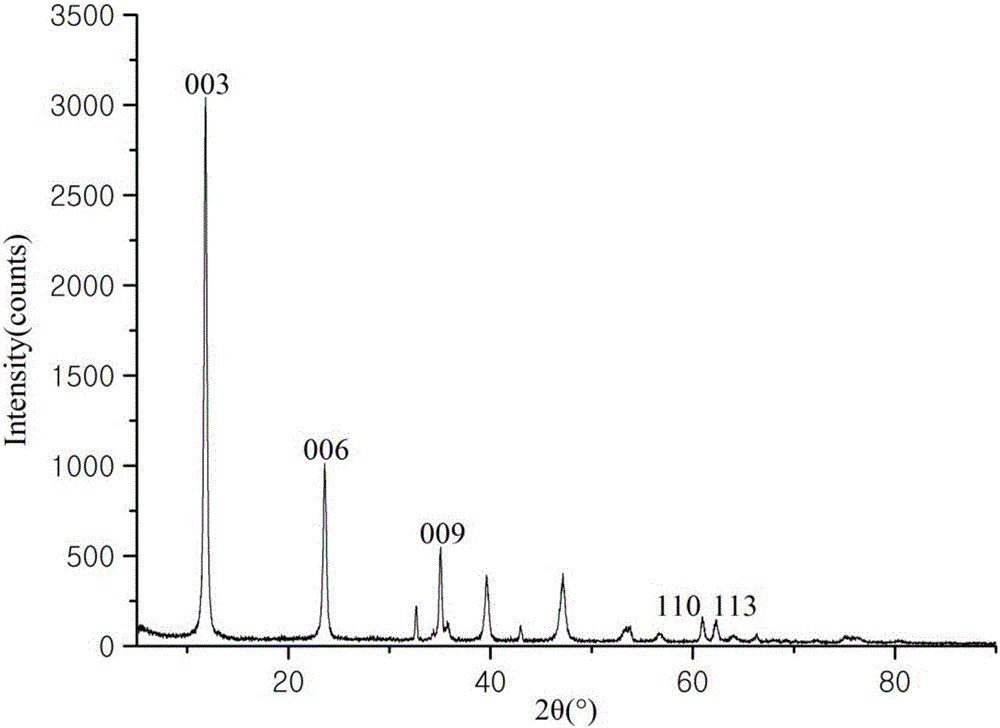

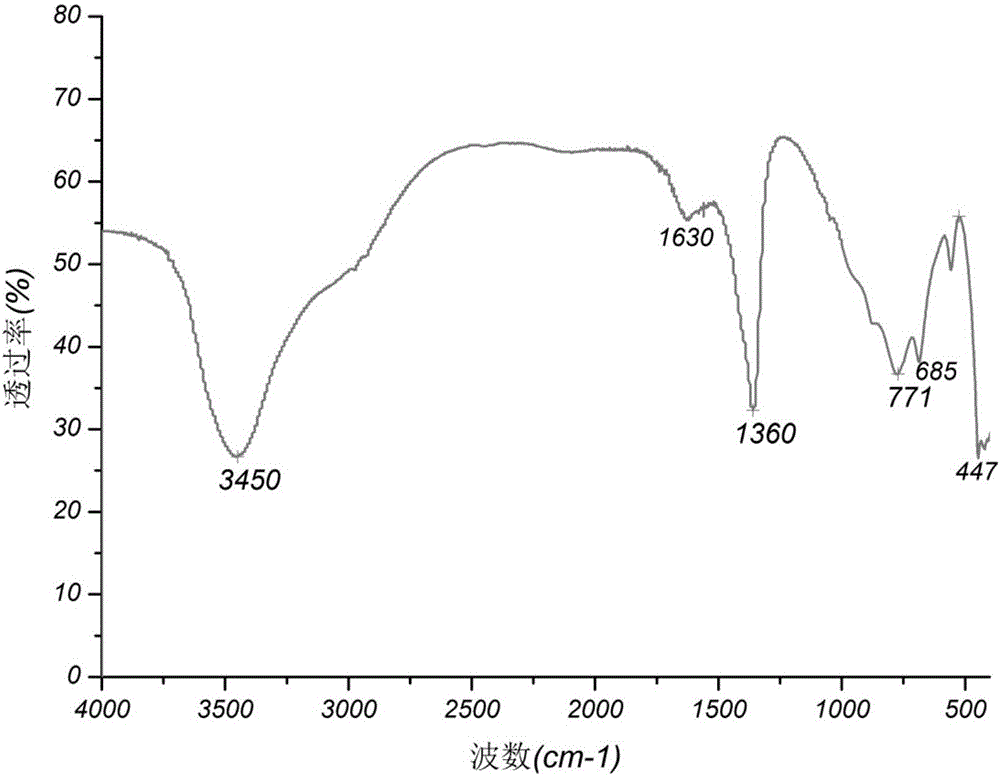

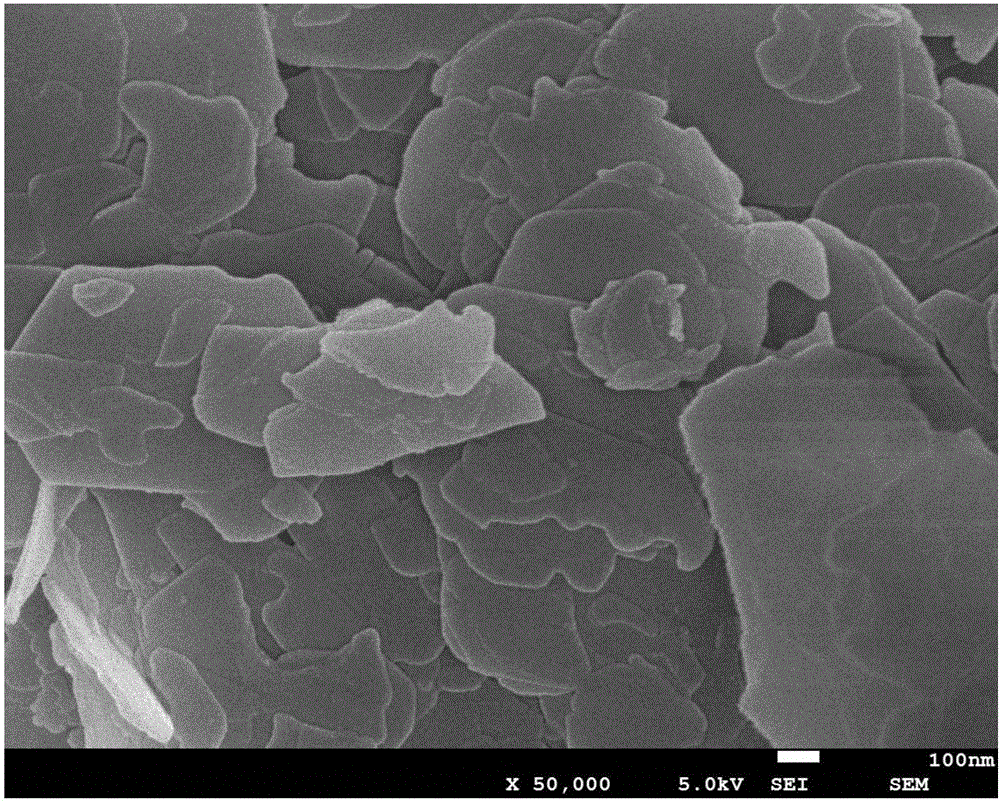

[0065] From the characterization results of the synthesized magnesium-aluminum hydrotalcite, it can be seen that, figure 1 The three diffraction peaks of X-ray 003, 006, and 009 in X-ray have a multiple relationship, indi...

Embodiment 2

[0067] (1) Weighing: Weigh 0.03mol of magnesium nitrate hexahydrate, 0.01mol of aluminum nitrate nonahydrate, and 0.36mol of urea;

[0068] (2) Dissolving and subpackaging: Dissolve magnesium nitrate, aluminum nitrate and urea in 100mL deionized water at room temperature, divide into two equal parts, install them in microwave digestion tanks, and seal them;

[0069] (3) Microwave homogeneous hydrothermal synthesis: place the microwave digestion tank in a microwave digestion apparatus, and heat at a set temperature of 150°C for 60 minutes to complete the synthesis;

[0070] (4) Washing and drying: Pour out all the solids and liquids in the microwave tank, wash with deionized water and absolute ethanol, dry under vacuum at 105°C, grind and store.

[0071] From the characterization results of the synthesized magnesium-aluminum hydrotalcite, it can be seen that, Figure 5 The three diffraction peaks of X-ray 003, 006, and 009 in X-ray have a multiple relationship, indicating that...

Embodiment 3

[0073] (1) Weighing: Weigh 0.03mol of magnesium nitrate hexahydrate, 0.01mol of aluminum nitrate nonahydrate, and 0.27mol of urea;

[0074] (2) Dissolving and subpackaging: Dissolve magnesium nitrate, aluminum nitrate and urea in 100mL deionized water at room temperature, divide into two equal parts, install them in microwave digestion tanks, and seal them;

[0075] (3) Microwave homogeneous hydrothermal synthesis: place the microwave digestion tank in a microwave digestion apparatus, and heat at a set temperature of 140°C for 40 minutes to complete the synthesis;

[0076] (4) Washing and drying: Pour out all the solids and liquids in the microwave tank, wash with deionized water and absolute ethanol, dry under vacuum at 105°C, grind and store.

[0077] From the characterization results of the synthesized magnesium-aluminum hydrotalcite, it can be seen that, Figure 9 The three diffraction peaks of X-ray 003, 006, and 009 in X-ray have a multiple relationship, indicating that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com