Method for treating high-salinity high-organic-matter industrial waste water

A technology of industrial waste water and treatment method, applied in the field of chemical industry, to achieve the effects of increasing green area, low operating cost, and reducing salt and organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

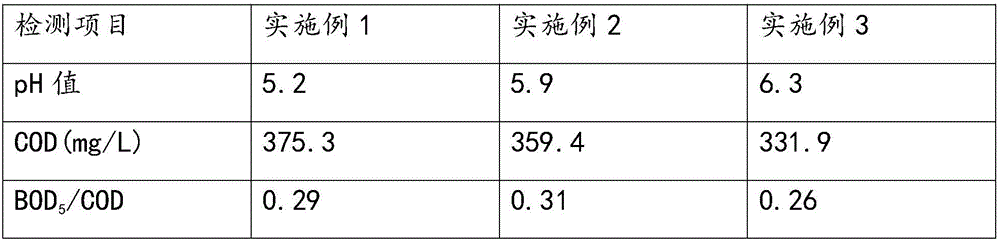

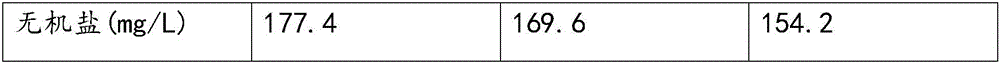

Embodiment 1

[0044] A treatment method for high-salt and high-organic-matter industrial wastewater, comprising the following steps:

[0045] A. Pretreatment

[0046] First, high-salt and high-organic industrial wastewater flows through multiple grids with gradually reduced grid gaps, and then is discharged into the sedimentation tank, and 10ppm coagulant (ferric chloride) is added for chemical treatment for 20 minutes, and then solid-liquid separation is carried out to remove Solid matter, that is, the supernatant of industrial wastewater;

[0047] B. Biological purification after dilution

[0048] First add salt-free water to the supernatant of the industrial wastewater described in step A for dilution, and then introduce it into the artificial wetland planted with purification plants for biological purification, and the artificial wetland includes the first biological purification zone, The second biological purification zone and the third biological purification zone, wherein the wate...

Embodiment 2

[0054] A treatment method for high-salt and high-organic-matter industrial wastewater, comprising the following steps:

[0055] A. Pretreatment

[0056] First, high-salt and high-organic industrial wastewater flows through multiple grids with gradually reduced grid gaps, and then discharged into the sedimentation tank, and 45ppm coagulant (ferric chloride) is added for chemical treatment for 30 minutes, and then solid-liquid separation is carried out to remove Solid matter, that is, the supernatant of industrial wastewater;

[0057] B. Biological purification after dilution

[0058] First add salt-free water to the supernatant of the industrial wastewater described in step A for dilution, and then introduce it into the artificial wetland planted with purification plants for biological purification, and the artificial wetland includes the first biological purification zone, The second biological purification zone and the third biological purification zone, wherein the water d...

Embodiment 3

[0064] A treatment method for high-salt and high-organic-matter industrial wastewater, comprising the following steps:

[0065] A. Pretreatment

[0066] First, high-salt and high-organic industrial wastewater flows through multiple grids with gradually reduced grid gaps, and then discharged into the sedimentation tank, adding 80ppm coagulant (ferric chloride) for chemical treatment for 20-40min, and then solid-liquid separation , remove the solid matter, promptly obtain the supernatant of industrial waste water;

[0067] B. Biological purification after dilution

[0068] First add salt-free water to the supernatant of the industrial wastewater described in step A for dilution, and then introduce it into the artificial wetland planted with purification plants for biological purification, and the artificial wetland includes the first biological purification zone, The second biological purification zone and the third biological purification zone, wherein the water depth of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com