External wall heat preservation material and preparation method thereof

A technology of external wall insulation and raw materials, applied in the field of building materials, can solve the problems of heavy workload, performance degradation of insulation materials, strong water absorption, etc., and achieve the effects of excellent waterproof and thermal insulation performance, excellent waterproof performance, energy saving and environmental protection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

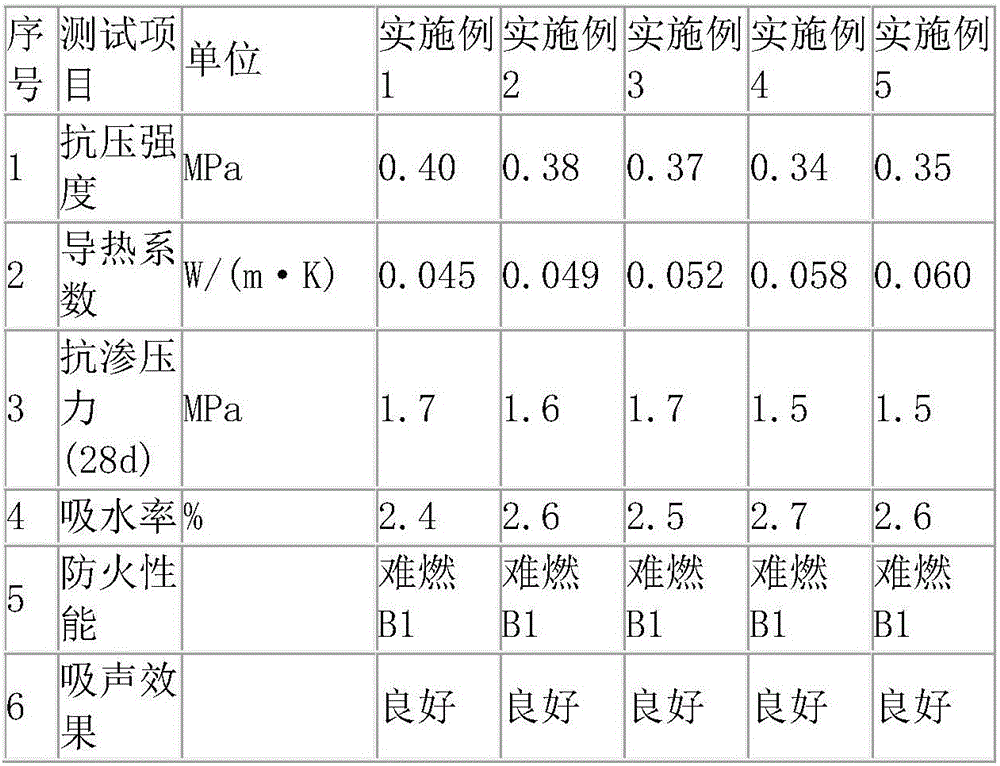

Examples

Embodiment 1

[0022] An external wall insulation material, comprising the following raw materials in parts by weight: 40 parts of fly ash, 100 parts of Portland cement, 25 parts of glass fiber, 22 parts of polyether polyol, tris(bromophenoxy)cyanurate 32 parts of acid ester, 28 parts of flame retardant (the weight ratio of decabromodiphenylethane and brominated epoxy resin is 3:5), and the smoke suppressant (the weight ratio of aluminum hydroxide and ferrocene is 3:2 ) 18 parts, coupling agent (3-aminopropyltriethoxysilane) 4 parts, hydrophobic agent (dodecyltrimethoxysilane) 3 parts, foam stabilizer (water-soluble silicone oil) 7 parts, elastic emulsion 7 servings.

[0023] The external wall insulation material comprises the following steps:

[0024] (1) Put Portland cement and tris(bromophenoxy)cyanurate into the elastic emulsion, stir and mix evenly at a speed of 3500r / min, then ultrasonically treat for 2.5h at an ultrasonic frequency of 25kHz;

[0025] (2) Add glass fiber, polyether p...

Embodiment 2

[0030] An external wall insulation material, comprising the following raw materials in parts by weight: 30 parts of fly ash, 80 parts of Portland cement, 20 parts of glass fiber, 10 parts of polyether polyol, tris(bromophenoxy)cyanurate 20 parts of acid ester, 20 parts of flame retardant (the weight ratio of decabromodiphenylethane and brominated epoxy resin is 3:5), smoke suppressant (the weight ratio of aluminum hydroxide and ferrocene is 3:2 ) 15 parts, coupling agent (3-aminopropyltriethoxysilane) 1 part, hydrophobic agent (dodecyltrimethoxysilane) 2 parts, foam stabilizer (water-soluble silicone oil) 5 parts, elastic emulsion 5 servings.

[0031] The external wall insulation material comprises the following steps:

[0032] (1) Put Portland cement and tris(bromophenoxy)cyanurate into the elastic emulsion, stir and mix evenly at a speed of 3500r / min, then ultrasonically treat for 2.5h at an ultrasonic frequency of 25kHz;

[0033] (2) Add glass fiber, polyether polyol and ...

Embodiment 3

[0038] An external wall insulation material, comprising the following raw materials in parts by weight: 50 parts of fly ash, 110 parts of Portland cement, 30 parts of glass fiber, 30 parts of polyether polyol, tris(bromophenoxy)cyanurate 40 parts of acid ester, 40 parts of flame retardant (the weight ratio of decabromodiphenylethane and brominated epoxy resin is 3:5), smoke suppressant (the weight ratio of aluminum hydroxide and ferrocene is 3:2 ) 20 parts, coupling agent (3-aminopropyltriethoxysilane) 5 parts, hydrophobic agent (dodecyltrimethoxysilane) 5 parts, foam stabilizer (water-soluble silicone oil) 8 parts, elastic emulsion 10 servings.

[0039] The external wall insulation material comprises the following steps:

[0040] (1) Put Portland cement and tris(bromophenoxy)cyanurate into the elastic emulsion, stir and mix evenly at a speed of 3500r / min, then ultrasonically treat for 2.5h at an ultrasonic frequency of 25kHz;

[0041] (2) Add glass fiber, polyether polyol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com